Single-tubular gas protection fiber thermal treatment device

A heat treatment device and gas protection technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of uneven performance of metal fiber materials, complex structure of heat treatment furnaces, low utilization rate of heat energy, etc., to ensure heat treatment performance and simple structure. , The effect of uniform and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

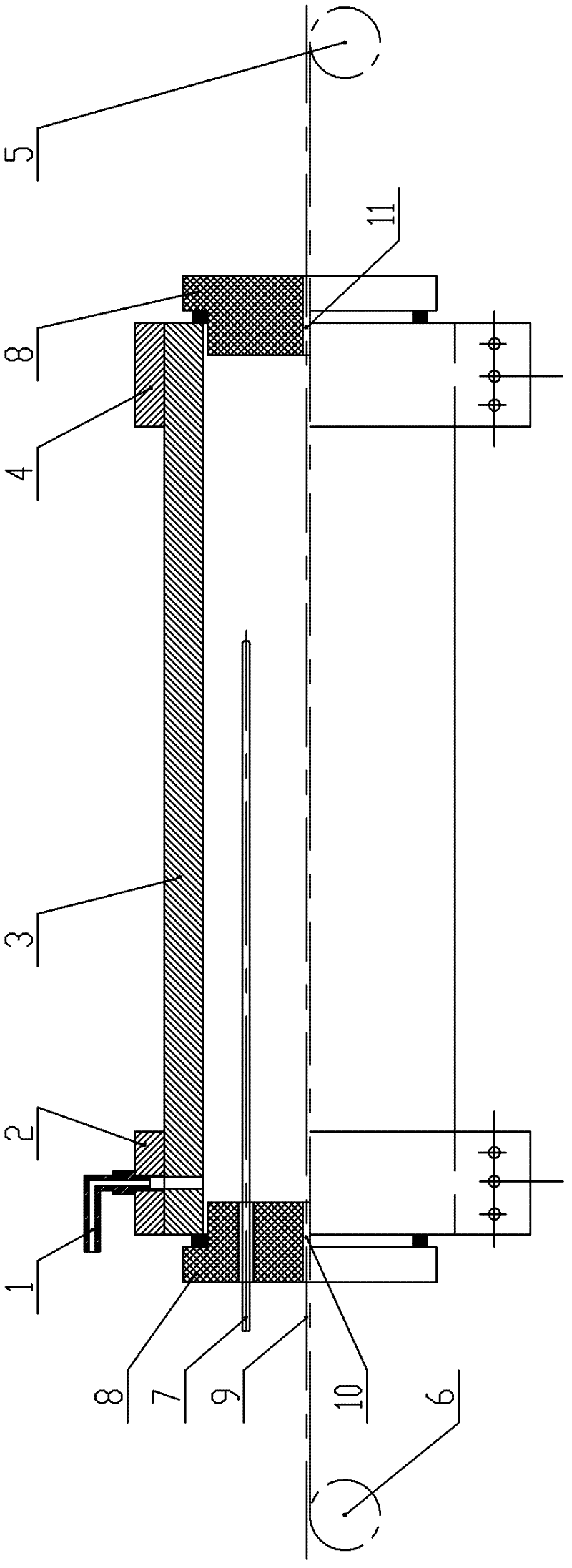

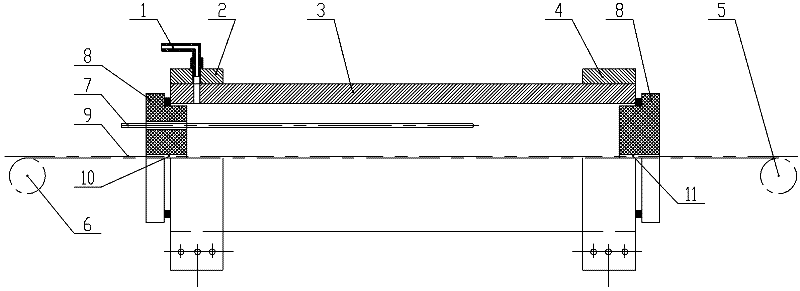

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 , including protective gas inlet 1, left electrode clamping end 2, heating tube 3, right electrode clamping end 4, right guide wheel 5, left guide wheel 6, temperature measuring thermocouple 7, head 8, fiber material 9. Material inlet 10, material outlet 11, etc.

[0014] Such as figure 1 As shown, the present invention is a single-tube gas-protected fiber heat treatment device, which includes a heating tube 3 made of superalloy with openings at both ends. The heating tube 3 is preferably made of GH3030 superalloy. The openings at both ends of the heating tube 3 are fixed with sealing heads 8 made of ceramic materials. Corresponding feed ports 10 and discharge ports 11 are respectively opened on the two seal heads 8 , the feed port 10 is located on the left seal head 8 , and the discharge port 11 is located on the right se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com