Formation method and equipment of acid cycle plate

A chemical formation method and acid cycle technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of uneven stratification of acid concentration and temperature, long time required, and large production site occupation, etc., to achieve uniform and controllable concentration and temperature, and improve Formation efficiency, elimination of polarization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

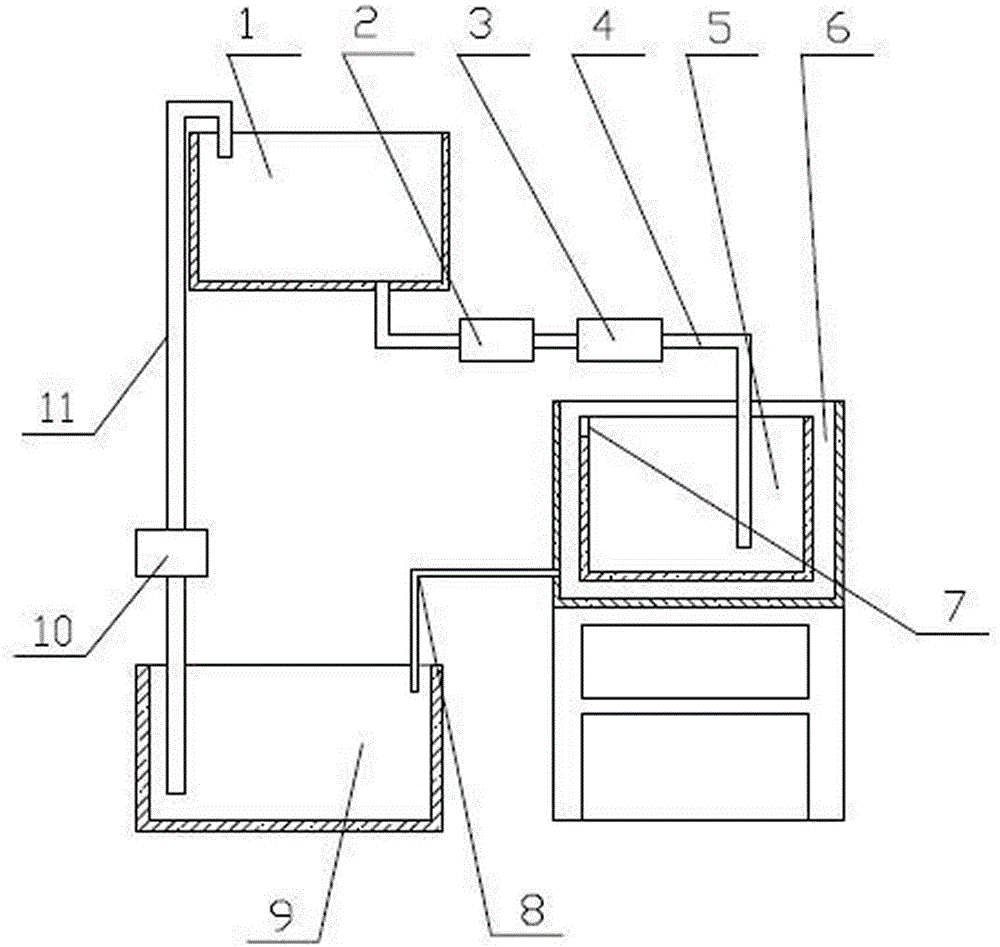

[0009] The technical scheme of the present invention is described in detail below in conjunction with specific examples: figure 1 As shown, this acid cycle plate formation device includes a formation tank 5, and a high-level acid storage tank 1, a flow regulating valve 2, a temperature-controlled heater 3, and an acid inlet pipe are arranged outside the formation tank 5. 4. Acid collection tank 6, acid outlet pipe 8, low-level acid storage tank 9, acid pump 10, acid return pipe 11, wherein the high-level acid storage tank 1 and the chemical conversion tank 5 are connected through the acid inlet pipe 4, the acid inlet The pipe 4 is provided with a flow regulating valve 2 and a temperature-controlled heater 3 in sequence, and an acid collection tank 6 is provided outside the formation tank 5, and an overflow port 7 is provided on the formation tank 5, between the acid collection tank 6 and the low-level acid storage tank 9 The lower acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com