Electromagnetic induction medium-frequency furnace and high-strength prestress steel strand production process

An electromagnetic induction, intermediate frequency furnace technology, applied in the improvement of process efficiency, metal material coating process, furnace and other directions, can solve the problem of affecting the forming quality of steel strands, poor heat treatment effect of steel strands, and lack of surface cleaning of steel strands, etc. problems, to ensure the effect of heat treatment, improve the quality of molding, save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

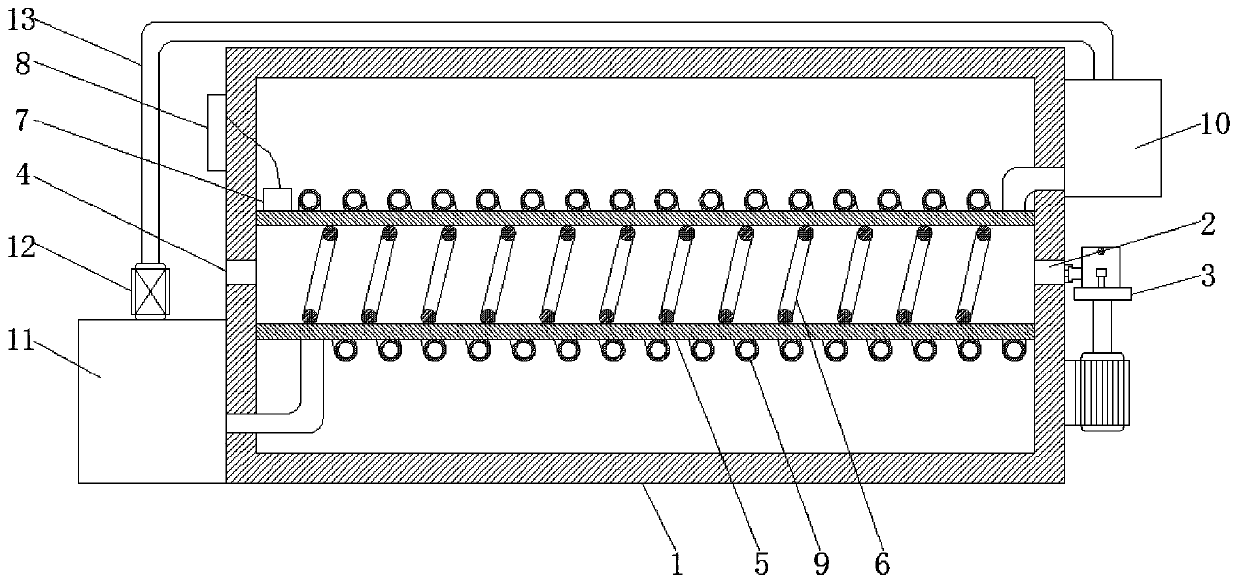

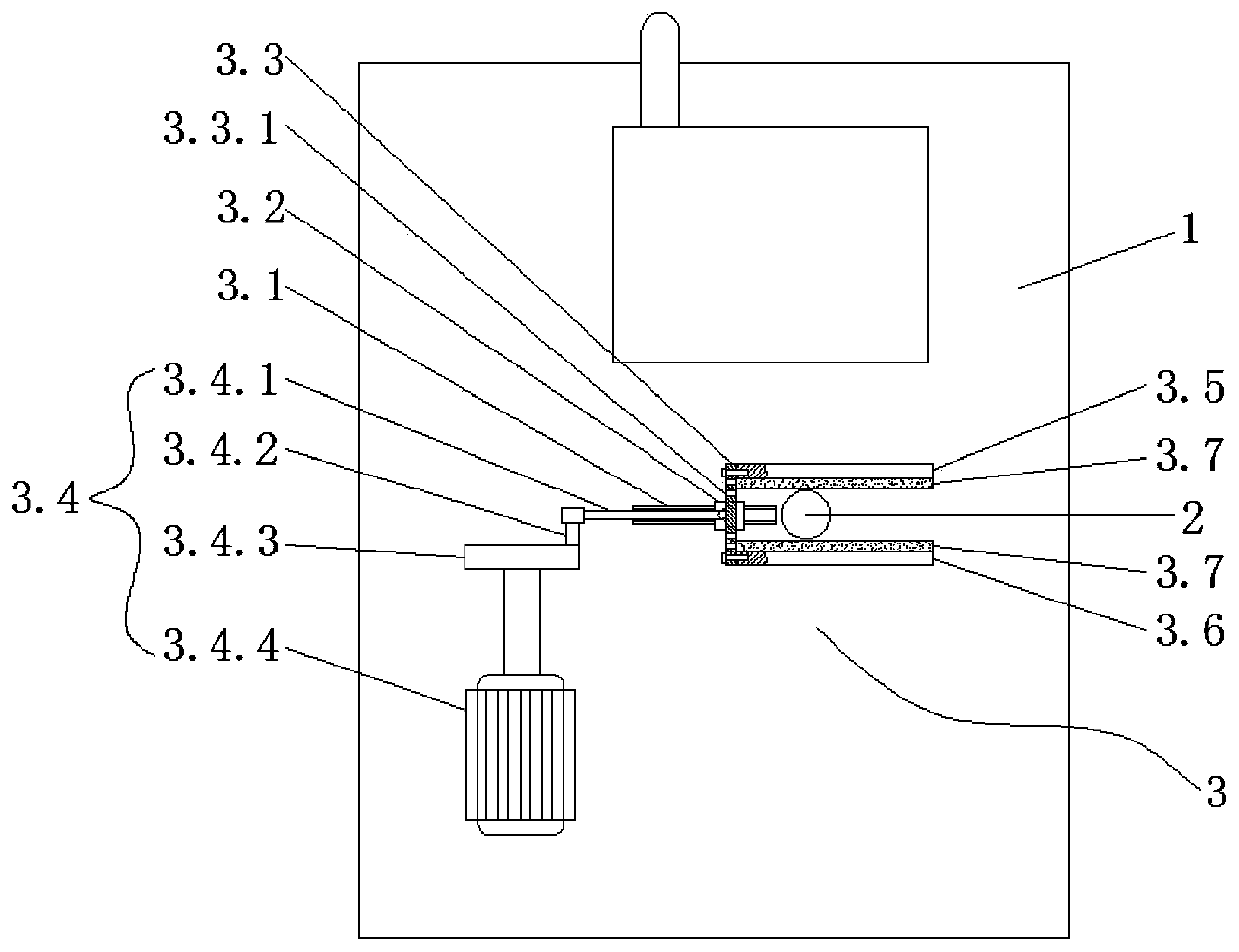

[0033] Such as Figures 1 to 3As shown, this embodiment provides an electromagnetic induction intermediate frequency furnace, including a furnace box 1, an inlet 2 is provided at one side of the furnace box 1, and a surface cleaning device 3 is provided on the side wall of the furnace box 1 near the inlet 2, and the surface cleaning device 3 includes a horizontal slide rail 3.1 arranged on the furnace box 1, a slide block 3.2 is slidably arranged on the horizontal slide rail 3.1, the slide block 3.2 is connected with a vertical mounting plate 3.3, and the end of the vertical mounting plate 3.3 away from the entrance 2 is connected There is a reciprocating movement mechanism 3.4, and the upper and lower ends of the vertical mounting plate 3.3 are detachably connected to the horizontal mounting plate A3.5 and the horizontal mounting plate B3.6 respectively located above and below the entrance 2, and the horizontal mounting plate A3.5 and the horizontal mounting plate B3. 6 The s...

Embodiment 2

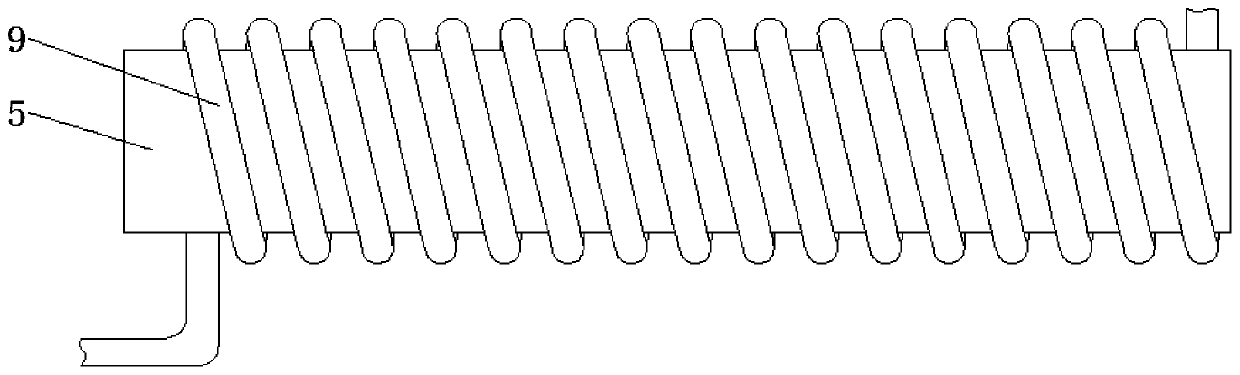

[0039] Such as Figures 1 to 3 As shown, this embodiment is further optimized on the basis of embodiment 1. Specifically, an outlet 4 corresponding to the inlet 2 is provided on the furnace box 1, and an outlet 4 located between the inlet 2 and the outlet 4 is provided in the furnace box 1 The heating pipeline 5 is provided with a plurality of electromagnetic induction coils 6 inside the heating pipeline 5, and the heating pipeline 5 is provided with a temperature sensor 7, and the temperature sensor 7 is electrically connected to a display screen 8 located on the outer wall of the furnace box 1.

[0040] The outer wall of the heating pipe 5 is spirally wound with a water-cooling pipe 9, one end of the water-cooling pipe 9 is connected to a water storage tank 10 located outside the furnace box 1, a control valve is arranged between the water storage tank 10 and the water-cooling pipe 9, and the other end of the water-cooling pipe 9 A water cooler 11 located outside the furnace...

Embodiment 3

[0043] The present embodiment provides a high-strength prestressed steel strand production process, comprising the following steps:

[0044] S1: Use carbon steel hot-rolled wire rods with a diameter of 13mm and a strength of 1400MPa or more, pickled with hydrochloric acid with a concentration of 40-200g / L, then washed with water, phosphated with a phosphating solution at 70°C, and then phosphated at 70°C Saponification of the saponified liquid;

[0045] S2: Draw the carbon steel hot-rolled wire rod obtained in step S1 through a straight-in wire drawing machine, the drawing speed is 4m / s, the water cooling temperature is controlled at 40-50°C, and a steel wire 6 with a diameter of 5.05mm is drawn. 1 steel wire with a diameter of 5.25mm;

[0046] S3: the steel wire with a diameter of 5.25mm obtained in step S2 is used as a core wire, and 6 steel wires with a diameter of 5.05mm are used as side wires, and are plied with a plying machine to obtain a steel strand;

[0047] S4: St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com