Supporting plate type feeding tool for isothermal heat treatment process

A technology of isothermal heat treatment and process, applied in the field of heat treatment, it can solve the problems of accumulation of parts, uneven feeding speed, affecting the effect of heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

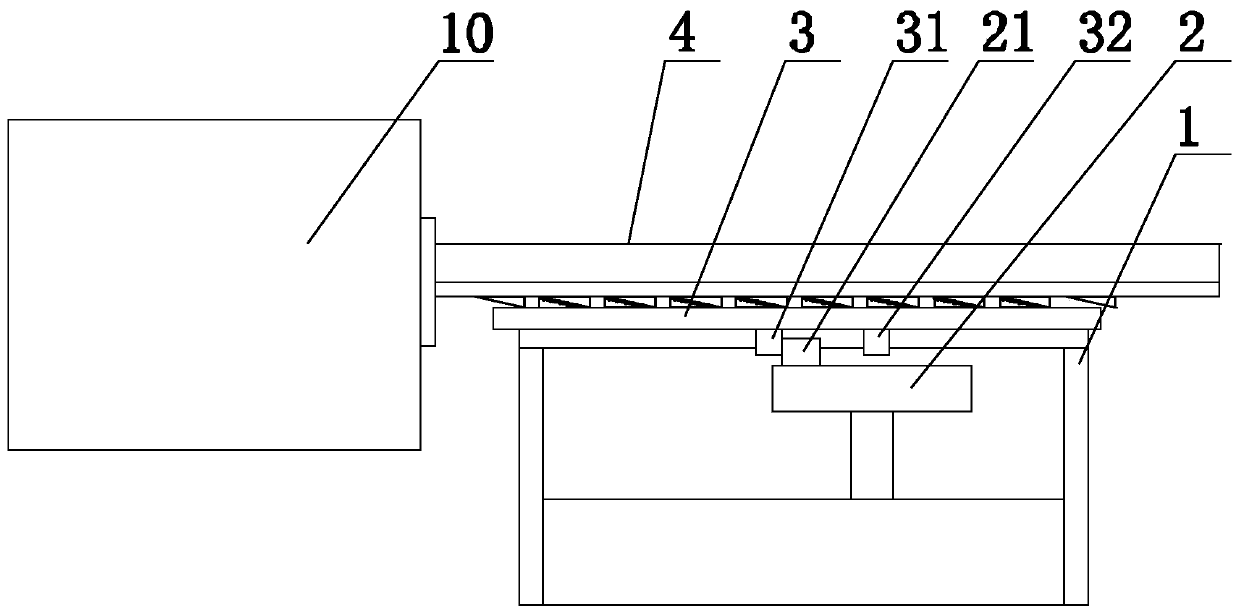

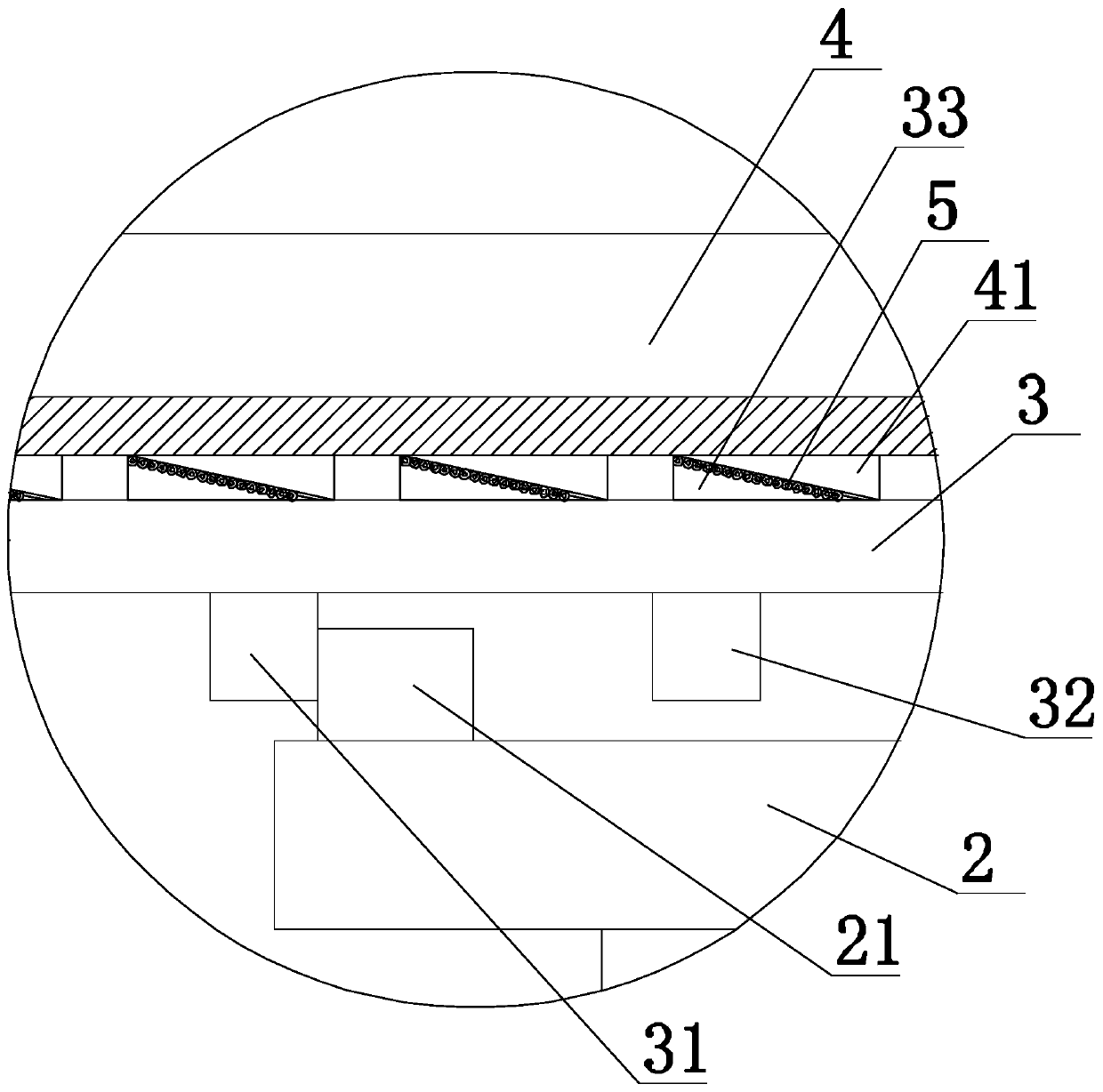

[0015] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a pallet-type feeding tooling for an isothermal heat treatment process proposed by the present invention, figure 2 It is a schematic structural diagram of the cooperation between the push bracket and the feeding tray of a pallet-type feeding tooling for an isothermal heat treatment process proposed by the present invention.

[0016] refer to figure 1 and 2 , a kind of isothermal heat treatment procedure that the present invention proposes uses pallet-type feeding tooling, comprises: installation frame 1, driving turntable 2, pushing bracket 3, feeding tray 4;

[0017] The mounting frame 1 is provided with a horizontally arranged slide rail, and the push bracket 3 can be slidably installed on the slide rail. The bottom of the push bracket 3 is provided with a first stopper 31 and a second stopper 32 arranged at intervals along the feeding direction. The top of the push bracket 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com