Method and apparatus for upsetting

A technology for upsetting and equipment, applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of increasing manufacturing costs and increasing the number of steps to prevent quenching distortion, Effect of eliminating corrective steps and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

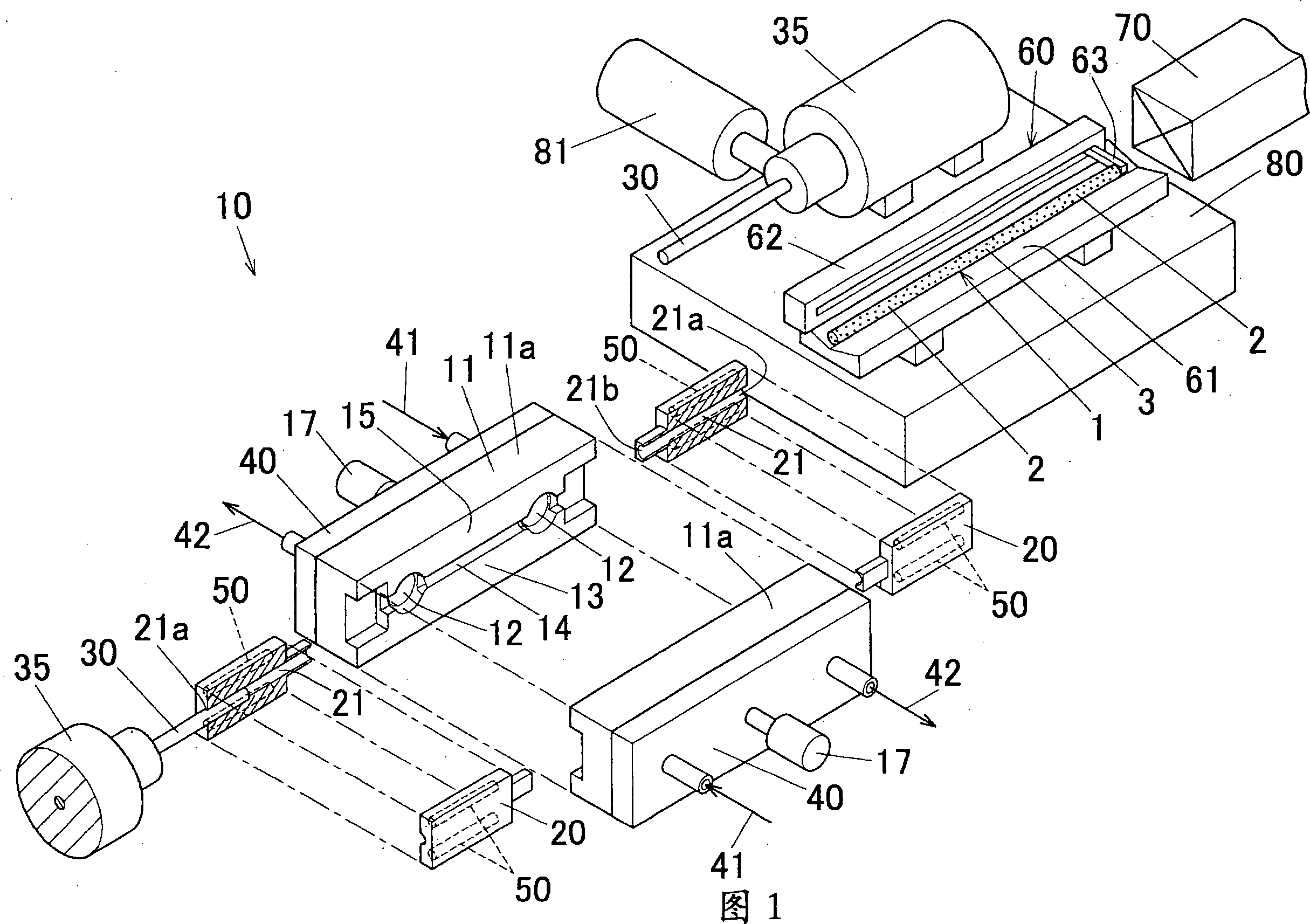

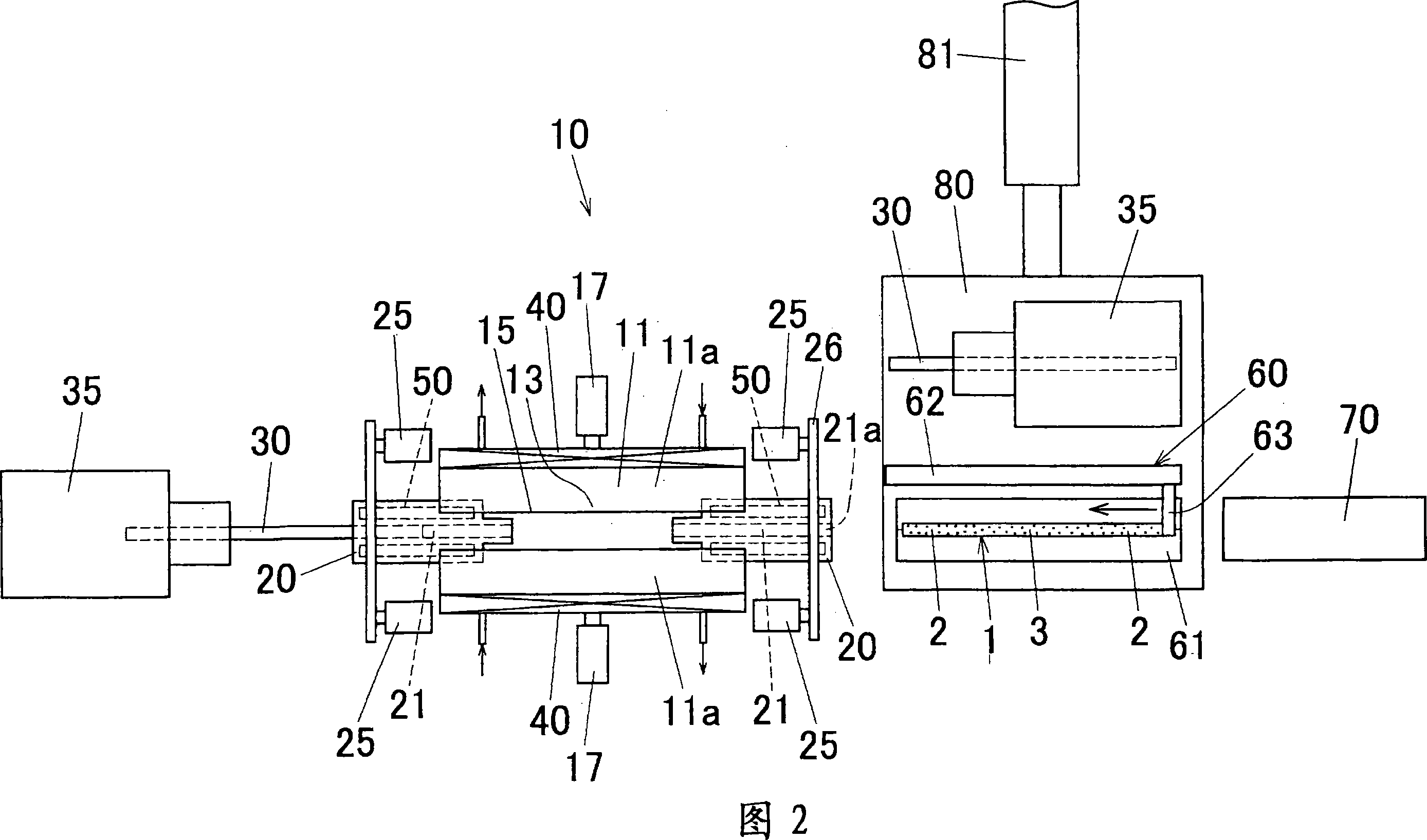

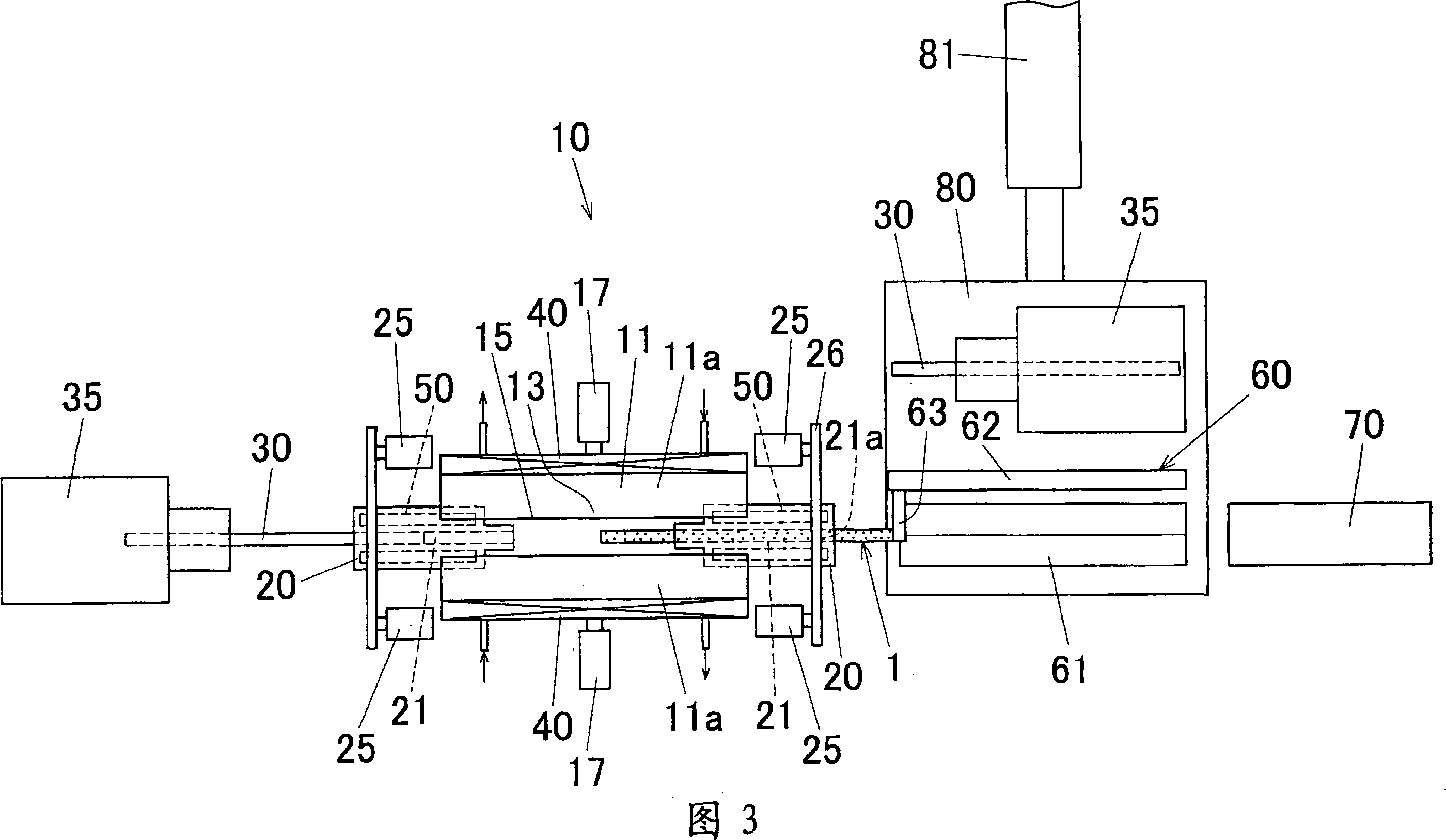

[0102] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0103] In FIG. 1, reference numeral "10" denotes an upset forging apparatus according to an embodiment of the present invention. Reference numeral "1" indicates a raw material.

[0104] In FIG. 9, reference numeral "5" denotes an upset manufactured product manufactured by the upset apparatus 10 of this embodiment. The upset manufactured product 5 is used as a preform for the manufacture of arms of vehicles such as automobiles or rail vehicles.

[0105] As shown in Figures 1 and 2, the raw material 1 is a solid straight rod-shaped material made of heat-treated aluminum alloy. The raw material 1 has a circular cross section and a constant diameter in the axial direction.

[0106] Since the above-mentioned heat-treated aluminum alloy is the material of the raw material 1, when expressed by an aluminum alloy number based on JIS (Japanese Industrial Standard), 2xxxx...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com