Induction quenching machining method of Cr12 roller

A technology of induction hardening and processing methods, which is applied in the field of heat treatment technology, can solve the problems of high energy consumption, large consumption of auxiliary tools, and high cost, and achieve the effects of uniform and fine metallographic structure, improved hardness uniformity, and improved core toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

[0028] A kind of induction hardening processing method of Cr12 roll, comprises the following steps:

[0029] (1) Put the clamped roll into a resistance furnace, heat the roll to 500-600°C and keep it warm for 4-10 hours. The holding time is affected by factors such as the size of the roll. The larger the size, the longer the holding time. This is to ensure that the roll The core can also be sufficiently heated.

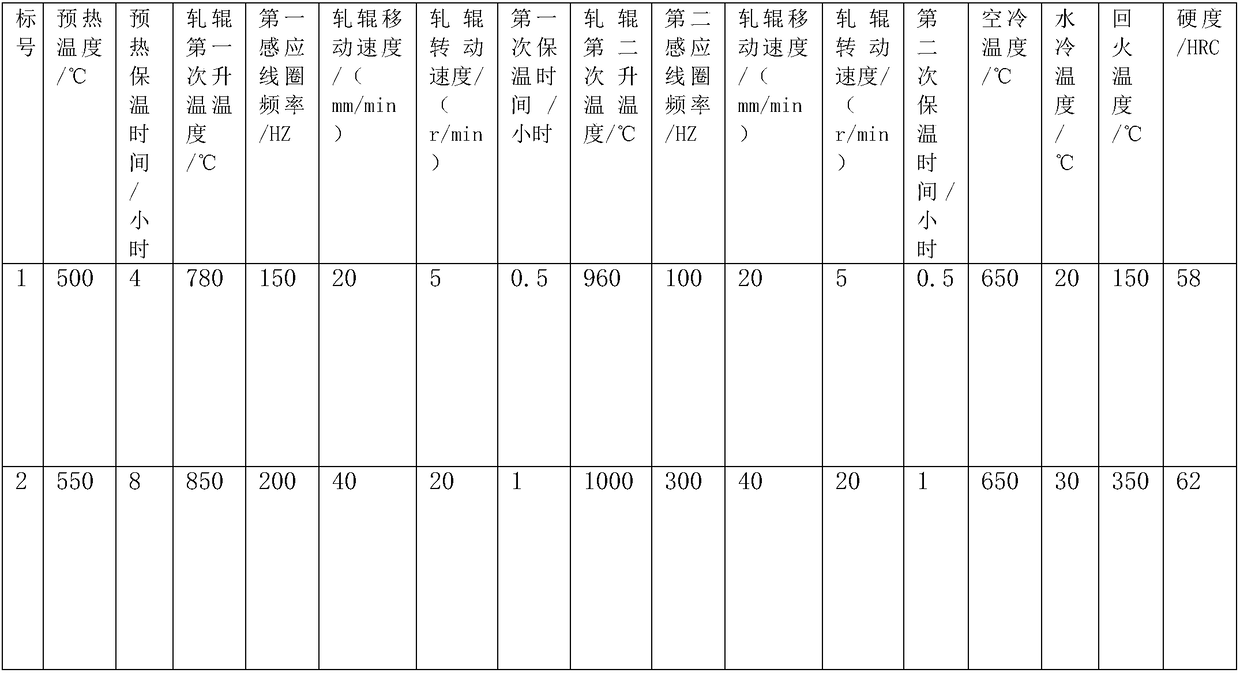

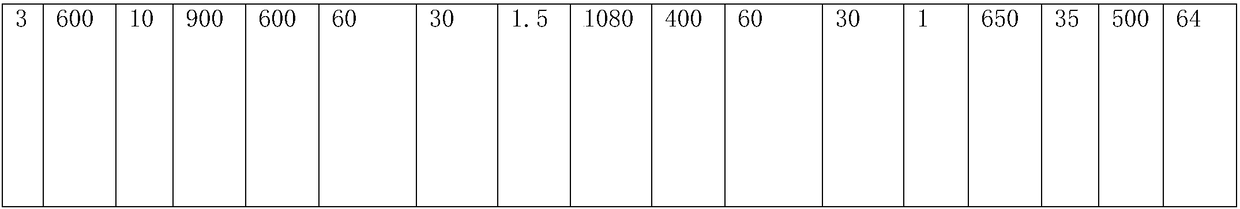

[0030] (2) Turn on the power supply of the first induction coil, and the preheating induction coil starts to heat. The roll is fixed on the frame, and as the frame rotates and moves, the roll passes through the first induction coil at a moving speed of 20-60 mm / min and a rotating speed of 5-30 rpm. Stop for a few seconds as the roll passes through the induction coil. The induction heating frequency is 150-600HZ, and the preferred induction coil heating frequency is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com