Detachable concrete test block mold with convenient demolding function

A technology for concrete test blocks and molds, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve problems such as reduced work efficiency, difficulty in demoulding, and damage to the mold itself, so as to solve difficulties in demoulding, avoid damage, and save storage effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

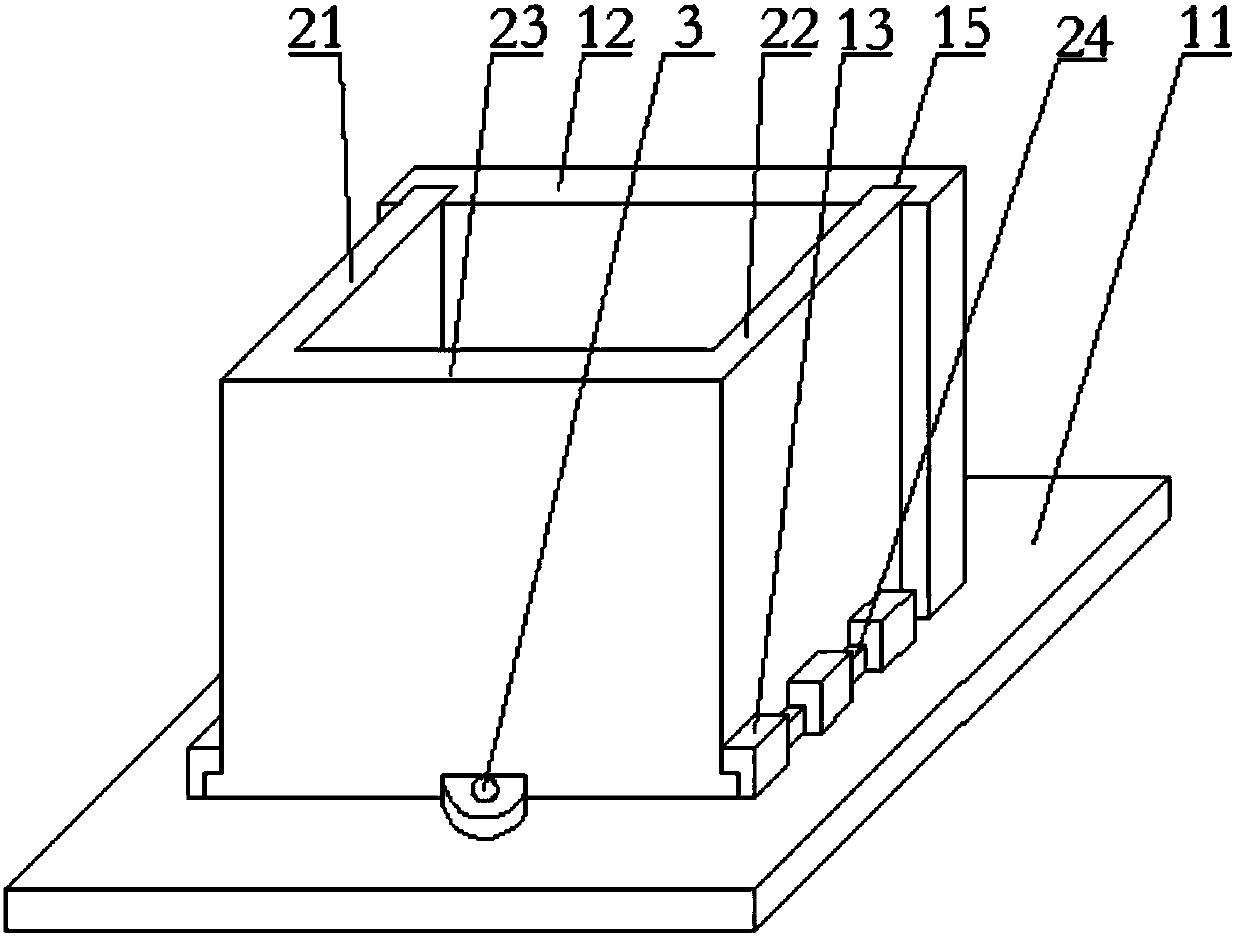

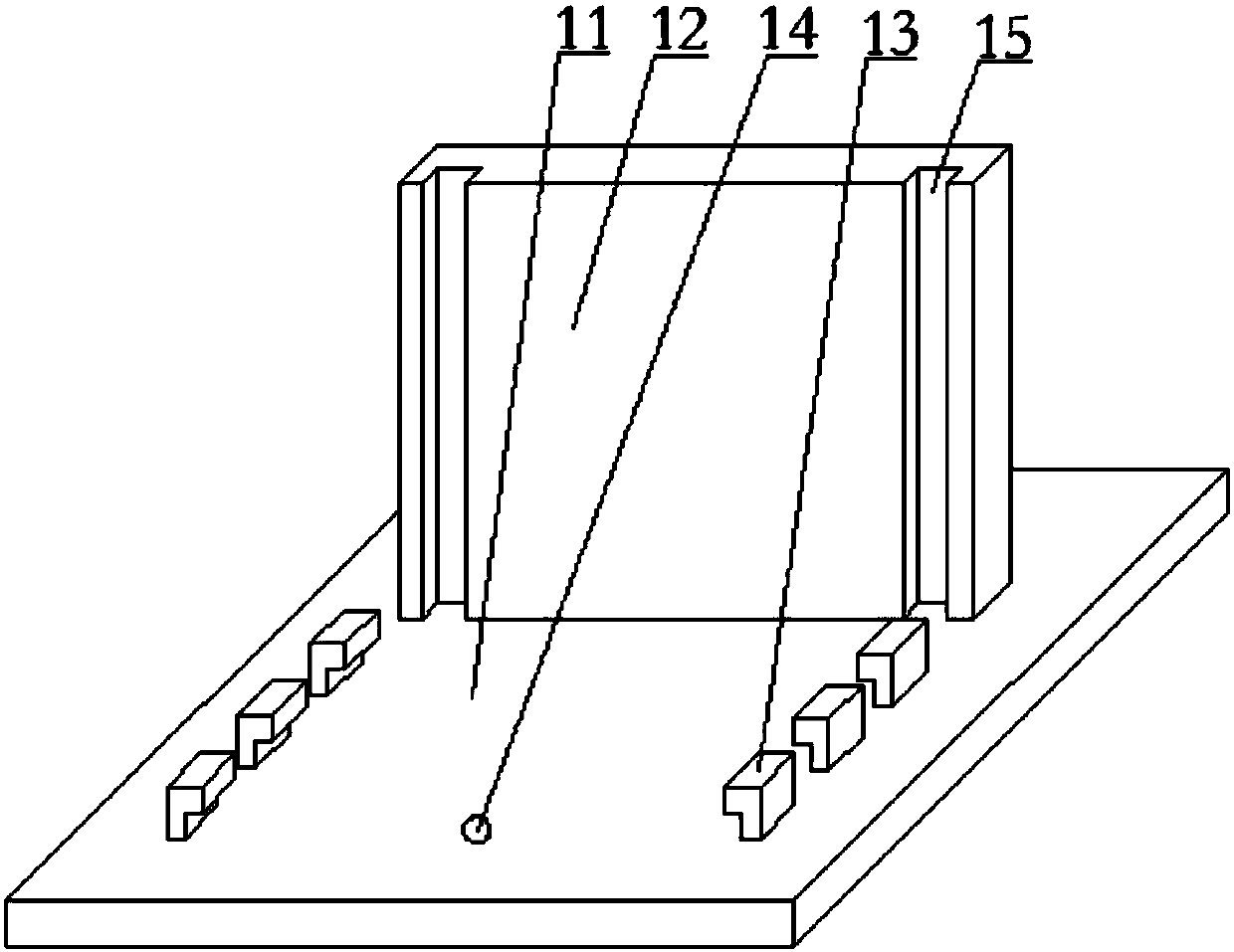

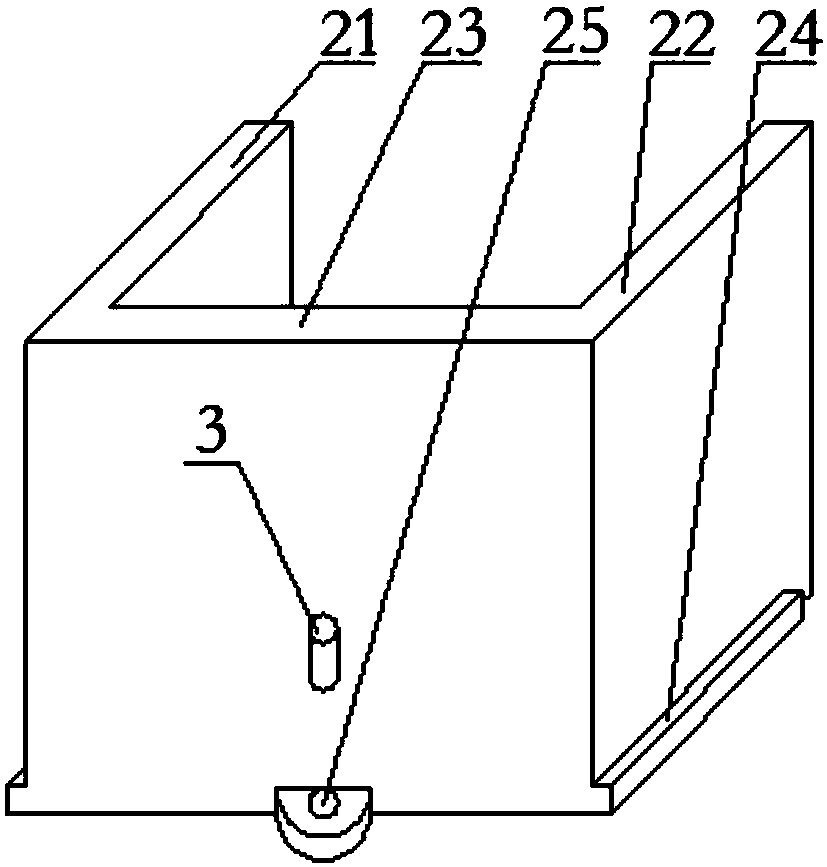

[0023] refer to figure 1 , a detachable concrete test block mould, which is convenient for demoulding, mainly consists of a base plate 11, a rear formwork 12, a left formwork 21, a right formwork 22, a front formwork 23 and pins 3. refer to figure 2 , the base plate 11 and the rear formwork 12 are poured and connected as a whole, the base plate 11 is provided with a limit hole A14 and a limit card groove 13, and the rear formwork 12 is provided with a limit groove 15; refer to image 3 , the left and right side templates and the front template 23 are poured and connected as a whole, the middle position of the front template 23 bottoms is also provided with a limiting hole B25, and the left and right template bottoms are all provided with a limiting clip 24.

[0024] Before pouring the test block, the mold is assembled first. The assembly process is as follows: first, align ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com