Preparation method of asphalt release agent

A technology of release agent and asphalt, which is applied in the field of material science, can solve the problems of high mobility and poor release effect of asphalt release agent, and achieve the effect of simple process, novel preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

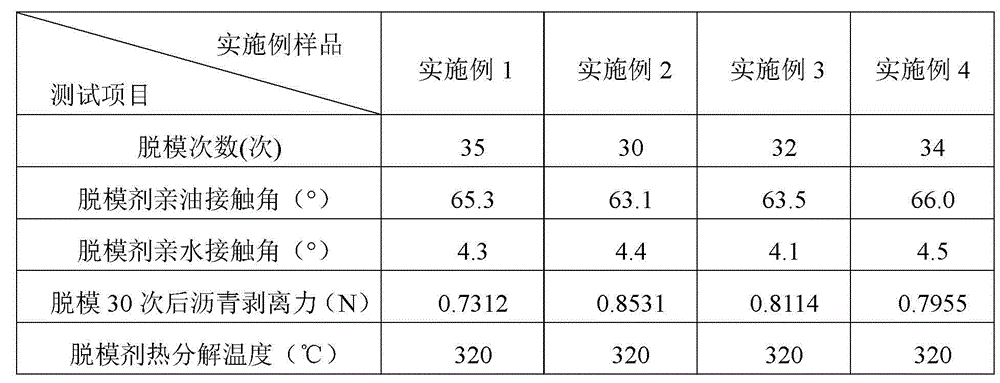

Examples

Embodiment 1

[0019] Taking 9.45 g of chloroacetic acid as raw material, the method for preparing asphalt release agent is realized by the following steps:

[0020] (1) Preparation of chloroacetic acid association liquid

[0021] Weigh 9.45 g of chloroacetic acid and add it to 28.35 g of ethanol and dissolve it with slight heat at 50 °C. The mass ratio of chloroacetic acid to ethanol is 1:3, and reflux at 80 °C for 3 hours to obtain a chloroacetic acid association liquid.

[0022] (2) Preparation of asphalt release agent

[0023] Measure 15.12 g of ethylenediamine into a 100 mL three-necked flask, pass through nitrogen protection, place the three-necked flask in an ice-water bath, place the chloroacetic acid association solution in a 50 mL dropping funnel, and add 18 drops / min Drop it into the three-necked flask at a speed of 1:1.6, that is, the mass ratio of chloroacetic acid to ethylenediamine is 1:1.6, stir evenly with a magnetic force, and react at 5 °C for 6 hours to obtain an asphalt...

Embodiment 2

[0025] Taking 9.45 g of chloroacetic acid as raw material, the method for preparing asphalt release agent is realized by the following steps:

[0026] (1) Preparation of chloroacetic acid association liquid

[0027] Weigh 9.45 g of chloroacetic acid and add it to 23.63 g of ethanol and dissolve it with slight heat at 50 °C. The mass ratio of chloroacetic acid to ethanol is 1:2.5, and reflux at 80 °C for 3 hours to obtain a chloroacetic acid association liquid.

[0028] (2) Preparation of asphalt release agent

[0029] Measure 11.34 g of ethylenediamine and place it in a 100 mL three-necked flask, protect it with nitrogen, place the three-necked flask in an ice-water bath, put the chloroacetic acid association liquid in a 50 mL dropping funnel, and add 18 drops / Drop it into a three-necked flask at a speed of 1 minute, that is, the mass ratio of chloroacetic acid to ethylenediamine is 1:1.2, stir evenly with a magnetic force, and react at 5 °C for 6 hours to obtain a white tra...

Embodiment 3

[0031] Taking 9.45 g of chloroacetic acid as raw material, the method for preparing asphalt release agent is realized by the following steps:

[0032] (1) Preparation of chloroacetic acid association liquid

[0033] Weigh 9.45 g of chloroacetic acid and add it to 37.80 g of ethanol and dissolve it with slight heat at 50 °C. The mass ratio of chloroacetic acid to ethanol is 1:4, and reflux at 80 °C for 3 hours to obtain a chloroacetic acid association liquid.

[0034] (2) Preparation of asphalt release agent

[0035] Measure 18.90 g of ethylenediamine into a 100 mL three-necked flask, pass through nitrogen protection, place the three-necked flask in an ice-water bath, place the chloroacetic acid association solution in a 50 mL dropping funnel, and add 18 drops / min Drop it into a three-necked flask at a speed of 1:2, that is, the mass ratio of chloroacetic acid to ethylenediamine is 1:2, stir evenly with a magnetic force, and react at 5 °C for 6 hours to obtain a white transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com