Graphene loudspeaker paper cone and production method thereof and loudspeaker

A vinyl speaker and manufacturing method technology, applied in the field of speakers, can solve the problems of paper brittleness, insufficient strength, poor toughness, etc., and achieve the effect of improving product quality, improving strength and toughness, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

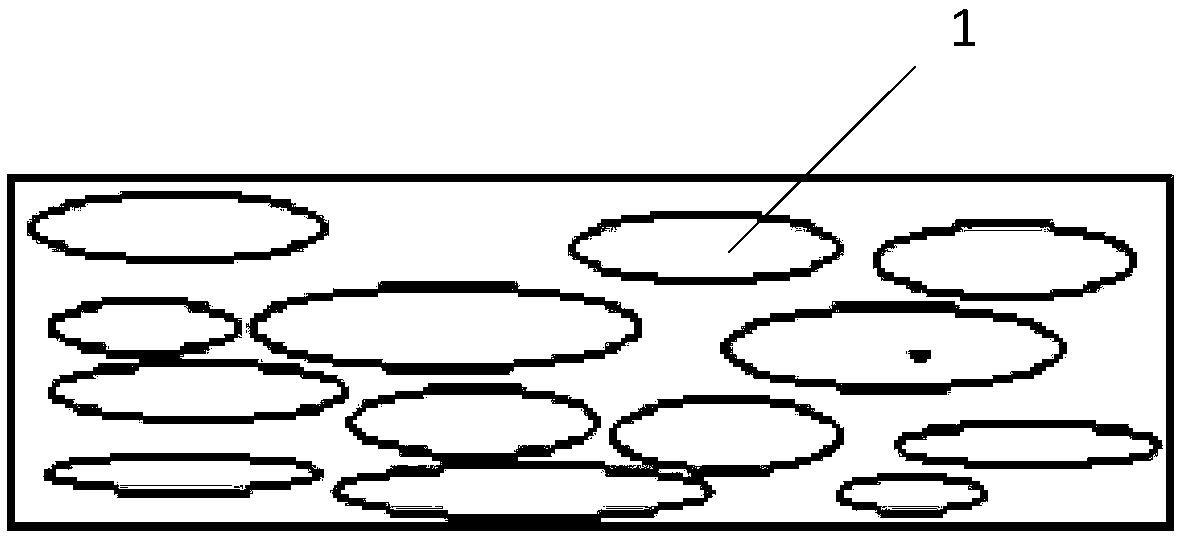

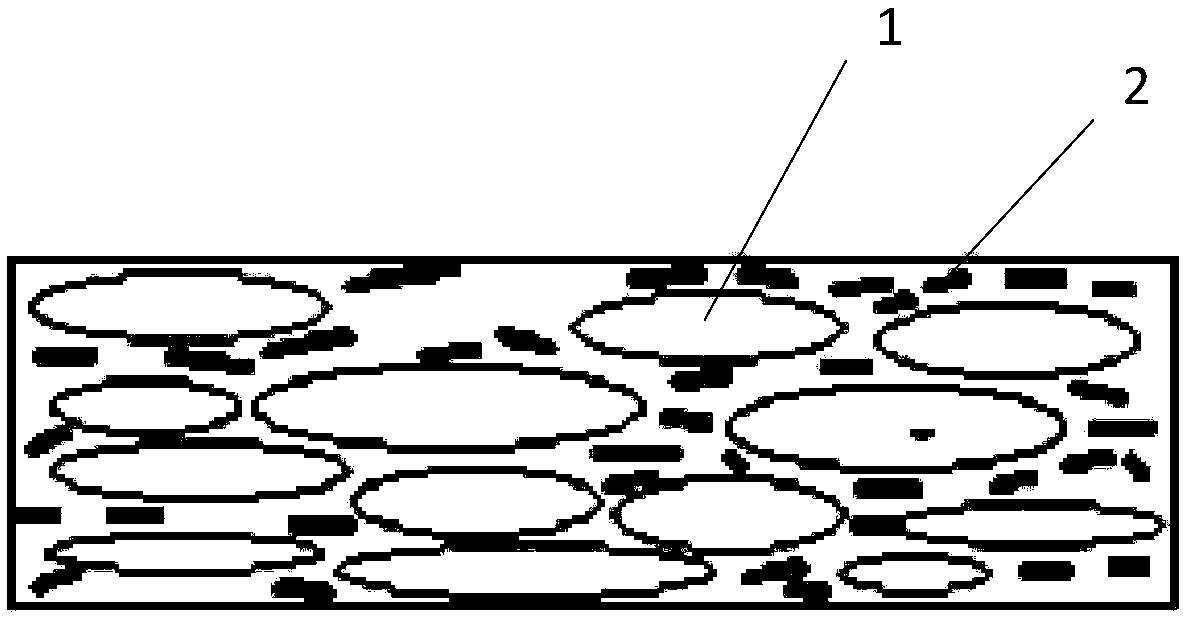

[0029] Such as figure 1 As shown, the graphene speaker cone provided by the embodiment of the present invention is made of pulp, and the pulp is mixed with graphene powder accounting for 0.5%-3% of the dry weight of the pulp. The particle size of graphene powder is 2000 mesh-3000 mesh. If it is to make a paper cone for a woofer, the graphene powder can be controlled to account for 0.5% of the weight of the dry pulp, and the graphene powder can be added to the pulp at a maximum of 3% of the weight of the dry pulp. Such as figure 2 As shown, when no graphene powder is added to the pulp, there are large pores between the pulp molecules 1, resulting in brittle pulp, low strength, insufficient toughness, easy to rot, and easy to break. Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com