Wear pump

A wear-resistant pump and pump body technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems such as difficulty in manufacturing larger-sized slurry pumps, difficulty in ejecting molds, and damage to molds and products, and achieves Prevents leakage, eases mold release, and improves wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

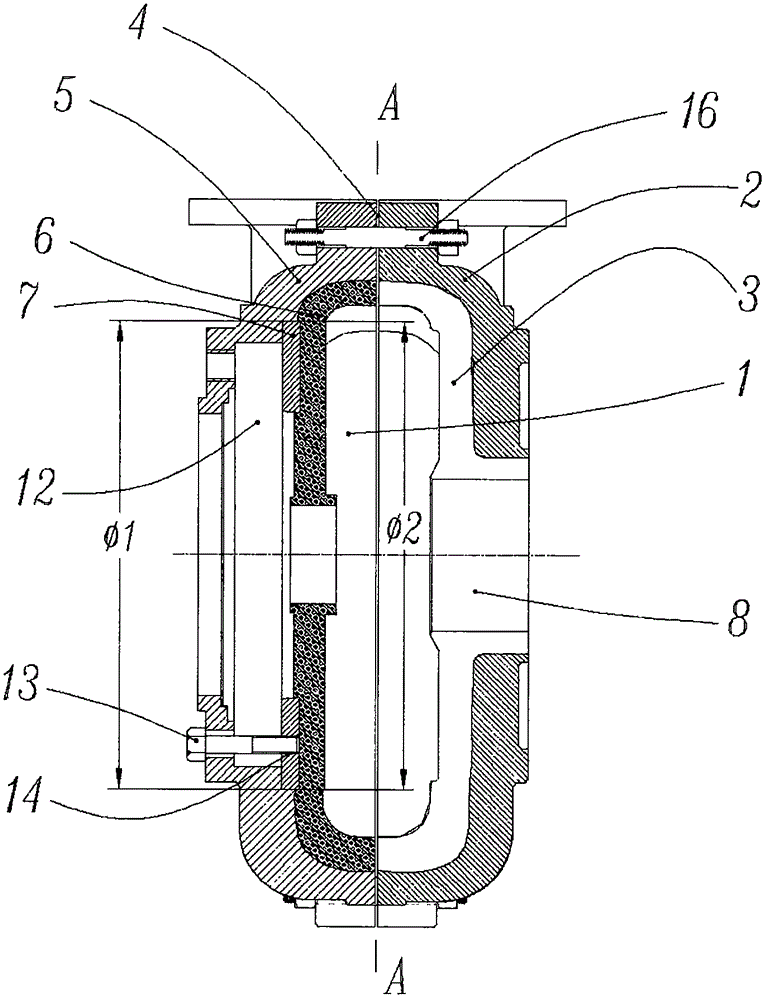

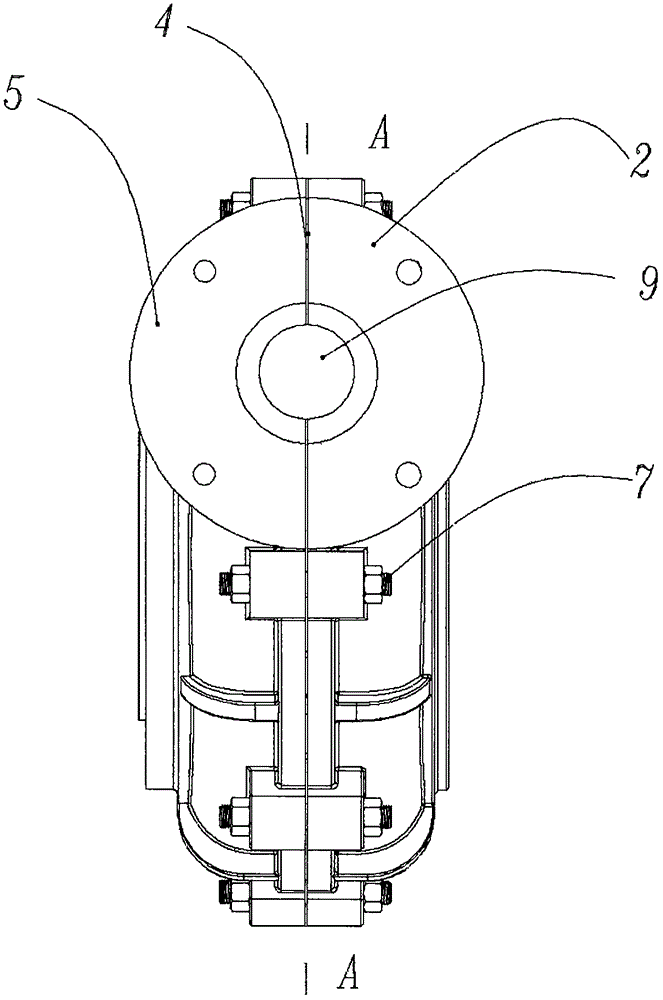

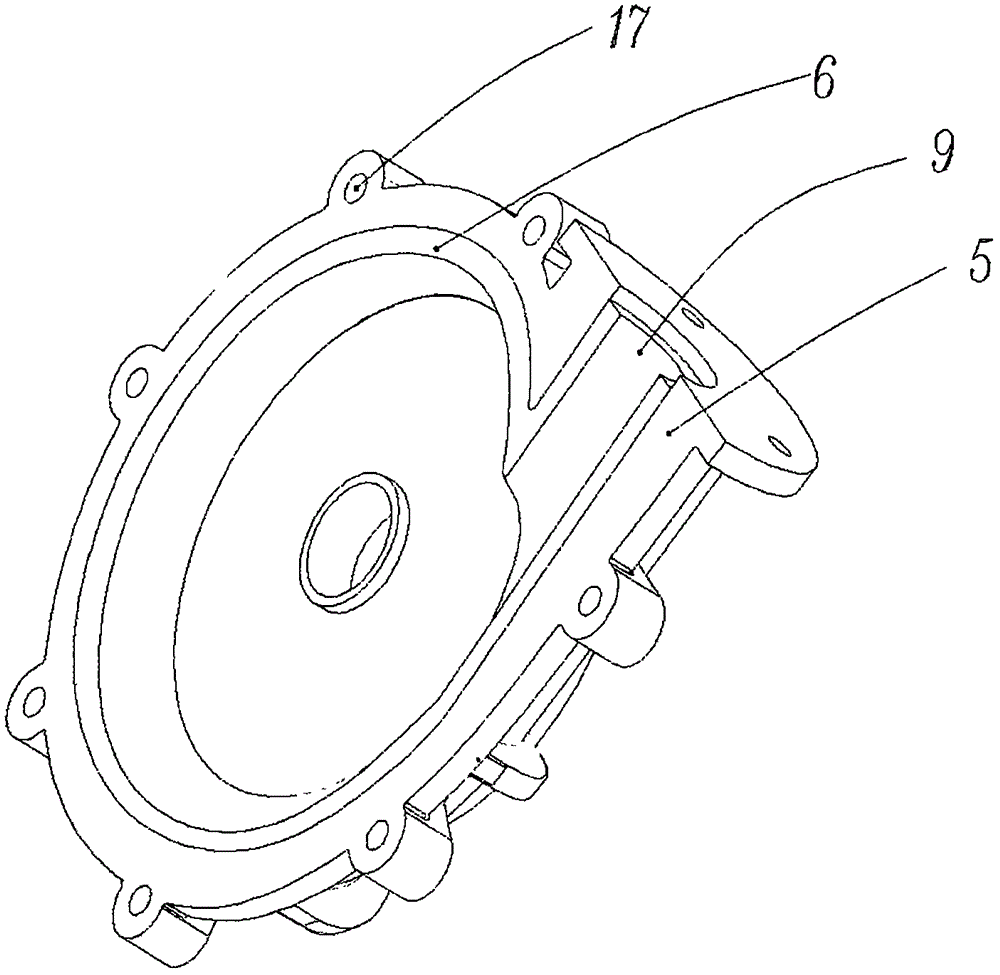

[0024] like figure 1 , figure 2 , image 3 As shown in the figure, the pressurized water chamber 1 is divided into two parts by the A-A plane, the front shell 2, the front lining 3 and the suction port 8 are on the same side of the A-A plane, and the rear shell 5 and the rear lining 6 are on the other side of the A-A plane. Side; the front inner lining 3 and the front shell 2 are manufactured separately during manufacture, and can be folded between the two; the rear inner lining 6 and the rear inner lining metal skeleton 7 are manufactured as an inseparable whole. The shaft φ2 is processed on the metal skeleton 7 of the rear lining, and the hole φ1 is processed on the rear shell 5. When the rear lining 6 is installed in the rear shell 5, φ1 and φ2 cooperate with each other. The matching type is clearance fit, and the fit clearance is 0.3 -0.5mm.

[0025] The sealing gasket 4 arranged on the A-A plane is made of rubber material with a thickness of 0.3-6mm. If it is too thin...

Embodiment 2

[0030] like Figure 4 As shown, in this embodiment, the front inner liner 3 and the front shell 2 are manufactured as an inseparable whole in the figure. The back lining 6 and the back lining metal frame 7 are manufactured as an inseparable whole. A shaft φ2 is processed on the metal skeleton 7 of the rear lining, and a hole φ1 is processed on the rear shell 5. When the rear lining 6 is installed in the rear shell 5, φ1 and φ2 cooperate with each other. The type of fit is a clearance fit, and the fit clearance is 0.2 mm-0.4mm. .

[0031] On the flow surfaces of the front lining 3 and the rear lining 6, ceramic sheets 15 are respectively arranged, and the ceramic sheets 15 can be a whole, or can be assembled by a plurality of ceramic sheets, and the ceramic sheets 15 are combined with a composite material through a bonding agent. into a whole.

[0032] Ejection thread 11 is arranged on the corresponding position of rear casing 5, when rear lining 6 needs to be ejected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com