Plastic worm injection forming mold

An injection molding and worm technology, applied in the field of mold manufacturing, can solve the problems of low efficiency, difficult to guarantee precision, and high production cost, and achieve the effects of high transmission efficiency, high product precision, and short injection cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

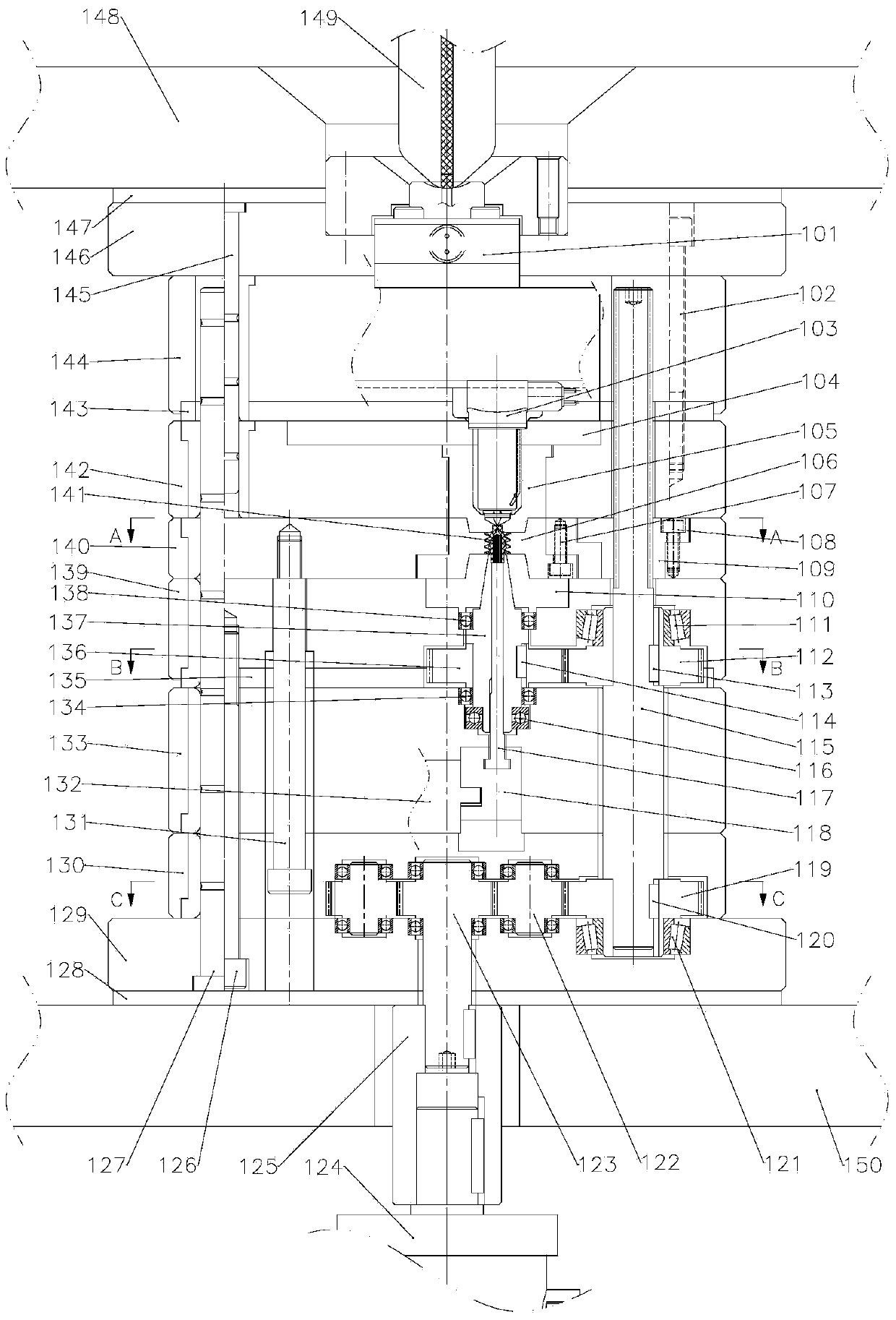

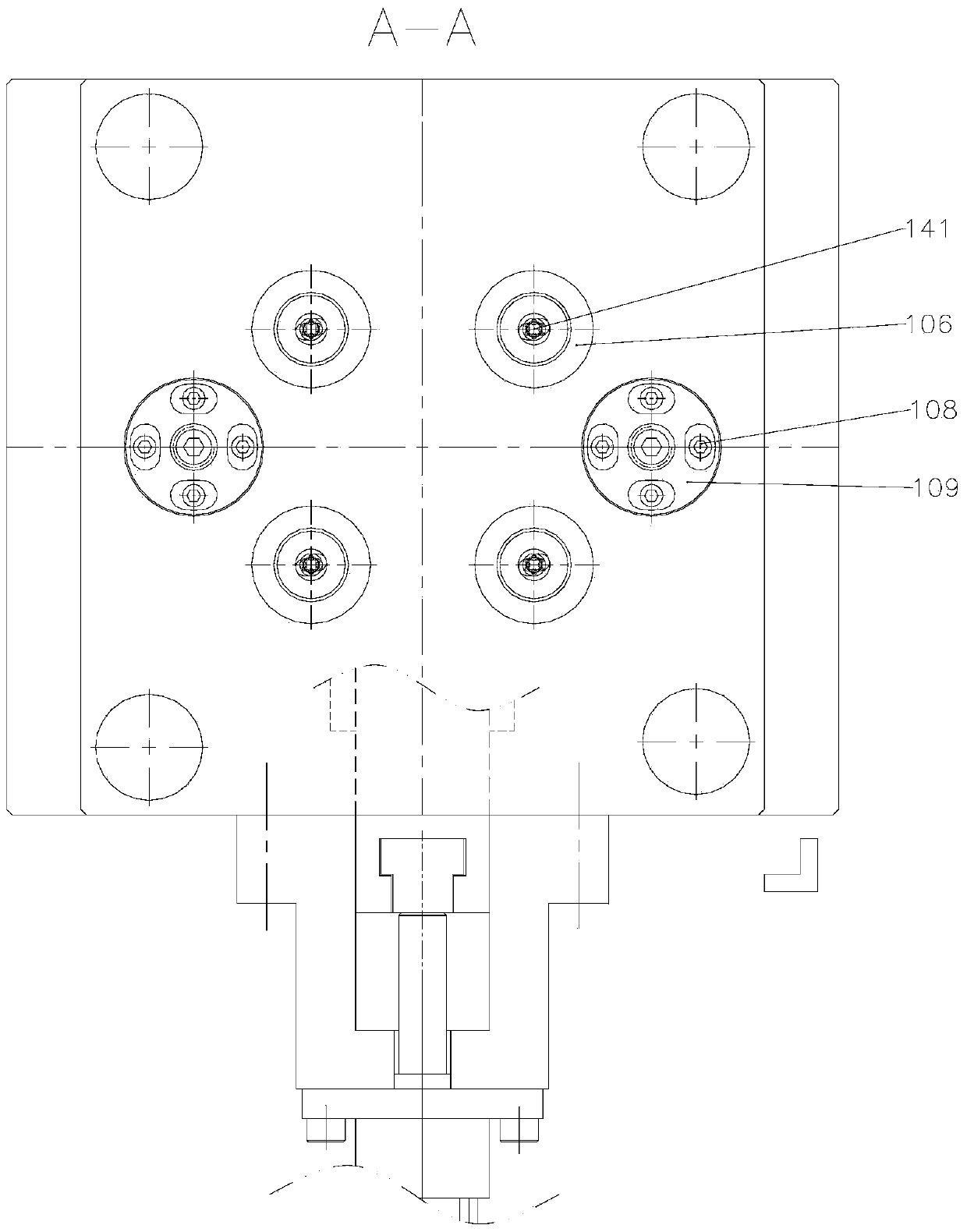

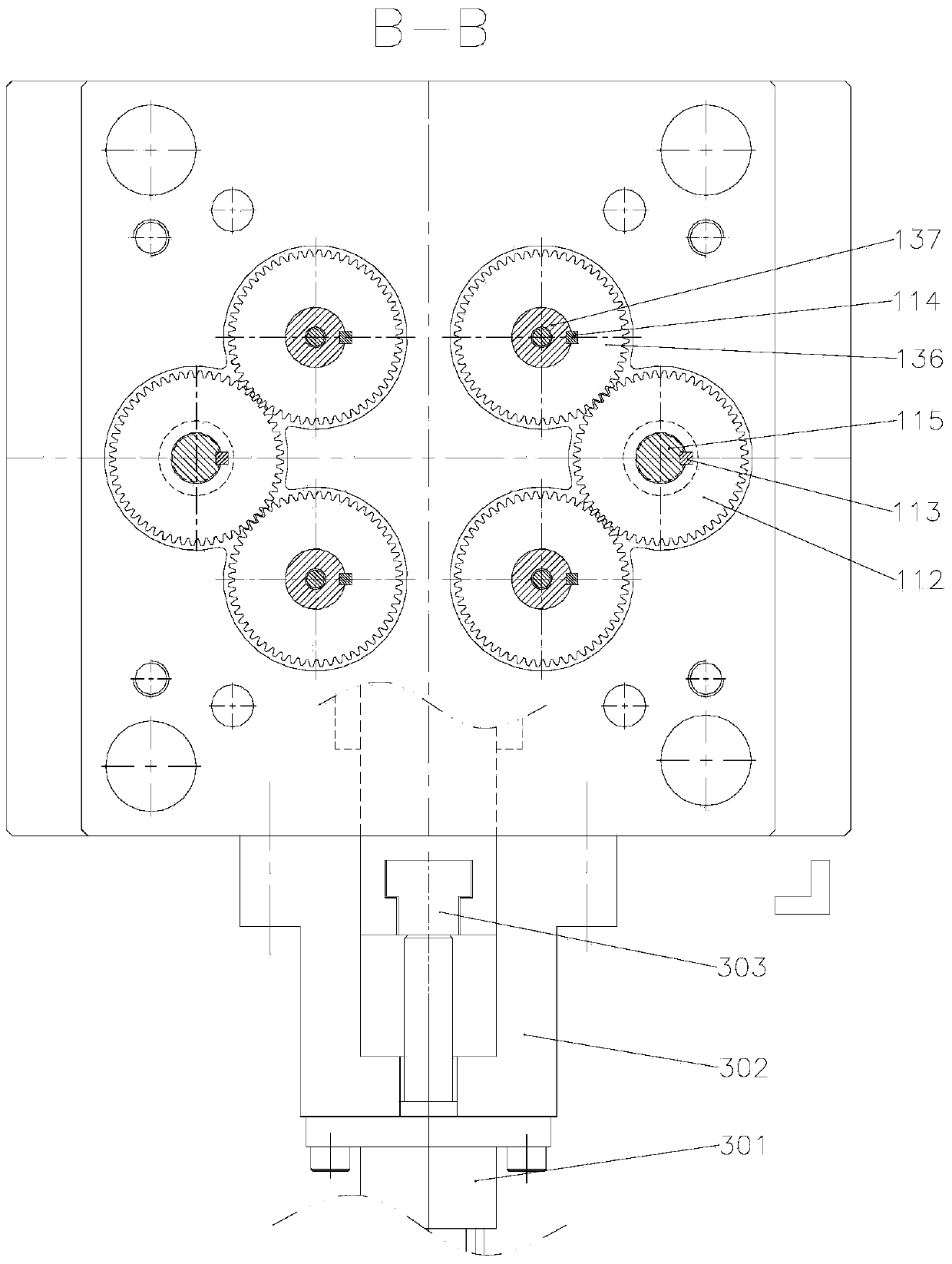

[0022] Such as figure 1 As shown, the plastic worm injection molding mold includes a fixed mold part and a movable mold part. The top plate 146 of the fixed mold part, the hot runner plate 144, and the fixed mold cavity plate 142 are fixedly connected with the fixed mold guide pillar 145 and the locking screw 102 in sequence, and the fixed mold cavity plate 142 center is provided with a fixed mold cavity 105, which is used for The fixed mold cavity pressing plate 104 is pressed and fixed on the fixed mold cavity plate 142 . The set hot runner system is placed in the fixed mold part, the sprue sleeve 101 of the hot runner system is connected with the nozzle 149 of the injection molding machine, and the outlet of the hot nozzle 103 of the hot runner system is connected with the worm cavity 141 . The heat insulation plate 147 fixed on the top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com