Basalt fiber grid reinforced concrete dismantling-free column formwork and preparation method thereof

A technology of basalt fiber and reinforced concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of inability to prepare dismantled formwork for columns with complex shapes, low cost, and doubtful impact on durability, so as to reduce the difficulty of formwork and manufacture Period, convenient preparation, and the effect of improving the overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing a basalt fiber grid-reinforced concrete non-dismantling column mold. The preparation method includes the following steps:

[0051] 1) According to the column design information, determine the shape parameters of the non-dismantling column template and the 2 parameters of the basalt fiber mesh;

[0052] 2) According to the shape parameter design of the free-dismantling template, the geometric parameters of the inward mold 3 and the outward mold 4 are obtained;

[0053] 3) Use additive manufacturing technology to make the inversion mold 3, and then fix the basalt fiber grid 2 on the inversion mold 3;

[0054] 4) Use additive manufacturing technology to make the overturning mold 4, which is combined with the inward turning mold 3 to form a whole;

[0055] 5) Pour ultra-high performance concrete between the inward turning form 3 and the outward turning form 4;

[0056] 6) Curing and demoulding to obtain the said basalt fiber g...

Embodiment 1

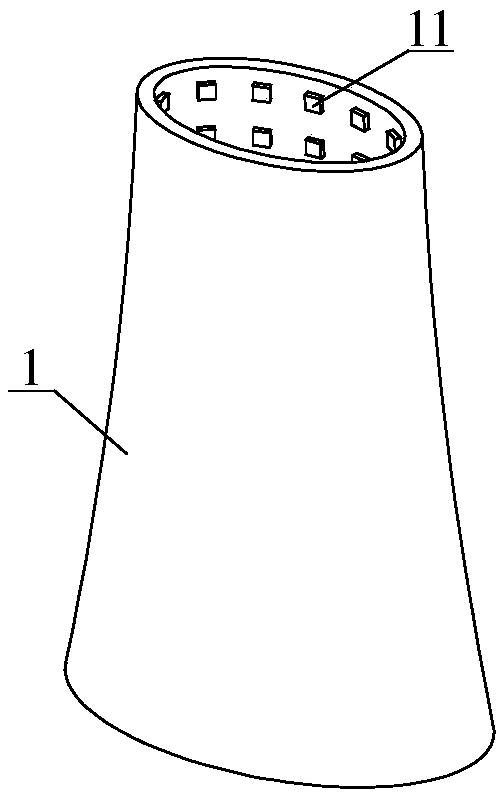

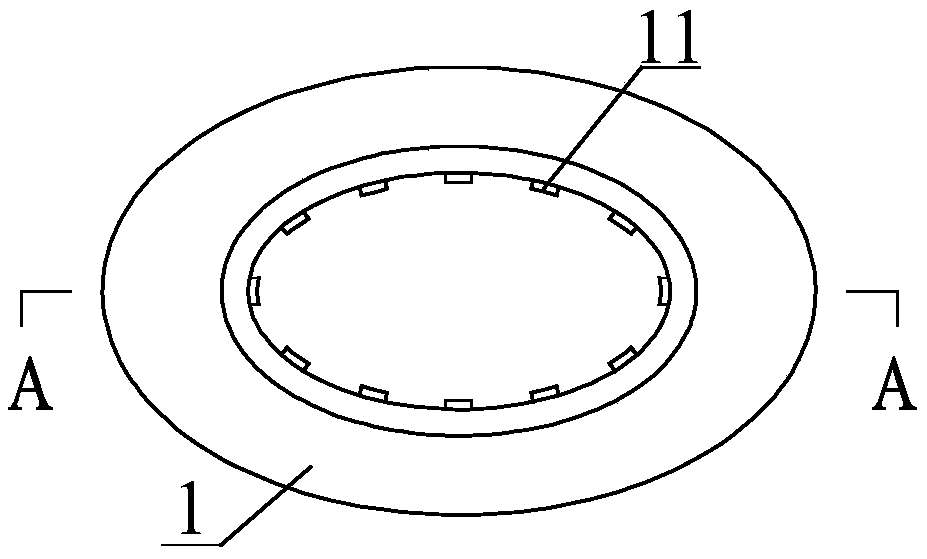

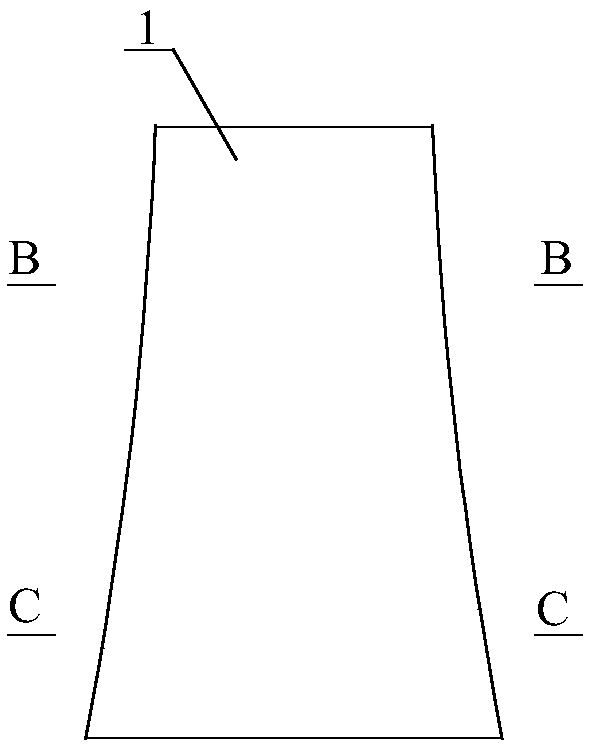

[0063] A basalt fiber grid reinforced concrete non-dismantling column form (such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 (Shown), the non-dismantling column formwork includes a hollow ultra-high performance concrete layer 1 and a basalt fiber grid 2 built into the wall of the hollow ultra-high performance concrete layer 1. The hollow ultra-high performance concrete layer 1 has a hollow elliptical cylindrical shape , The diameter of the upper bottom surface is smaller than the lower bottom surface, the thickness is 20mm, the slump extension is 750mm, the 28d compressive strength is 148.1MPa, and the flexural strength is 18.4MPa; there is a height on the inner surface of the hollow ultra-high performance concrete layer 1. It is a 6mm rectangular parallelepiped shear bump 11;

[0064] In the one-layer wall of the hollow ultra-high performance concrete layer, a layer of basalt fiber grids 2 is arranged along the circumferential direction of the layer wall...

Embodiment 2

[0082] A basalt fiber grid reinforced concrete non-dismantling column formwork. The dismantling-free column formwork includes a hollow ultra-high performance concrete layer 1 and a basalt fiber grid 2 built into the wall of the hollow ultra-high performance concrete layer 1. The hollow ultra-high performance The shape of the concrete layer 1 is a hollow square column, the thickness is 30mm, its slump extension is 550mm, the 28d compressive strength is 120MPa, and the flexural strength is 15.1MPa; the inner surface of the hollow ultra-high performance concrete layer 1 has a height of 10mm hemispherical shear bump 11;

[0083] In the one-layer wall of the hollow ultra-high performance concrete layer, two layers of basalt fiber grids 2 are arranged along the circumferential direction of the layer wall, the spacing between the two layers is 10mm, and the net spacing of the basalt fiber grids 2 is 12mm.

[0084] A preparation method of a basalt fiber grid reinforced concrete non-dismant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com