Method for preparing SiC3D/Al composite through vacuum pressure infiltration positive-pressure method

A vacuum pressure impregnation and composite material technology, which is applied in the field of composite material preparation, can solve the problems of difficult demoulding of molds and high manufacturing costs, reduce manufacturing costs, improve demoulding efficiency, and facilitate quality control and mechanical and physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

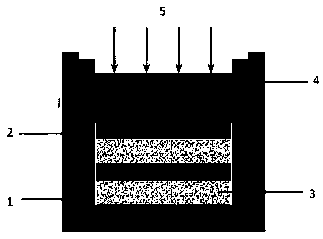

[0032] Such as figure 1 As shown, the vacuum pressure positive pressure impregnation method is used to prepare the composite material, specifically, the SiC is prepared according to the following steps 3D / Al composites.

[0033] S1. According to the prepared SiC 3D Design molds for the shape and size of / Al composite materials, and prepare soluble ceramic molds;

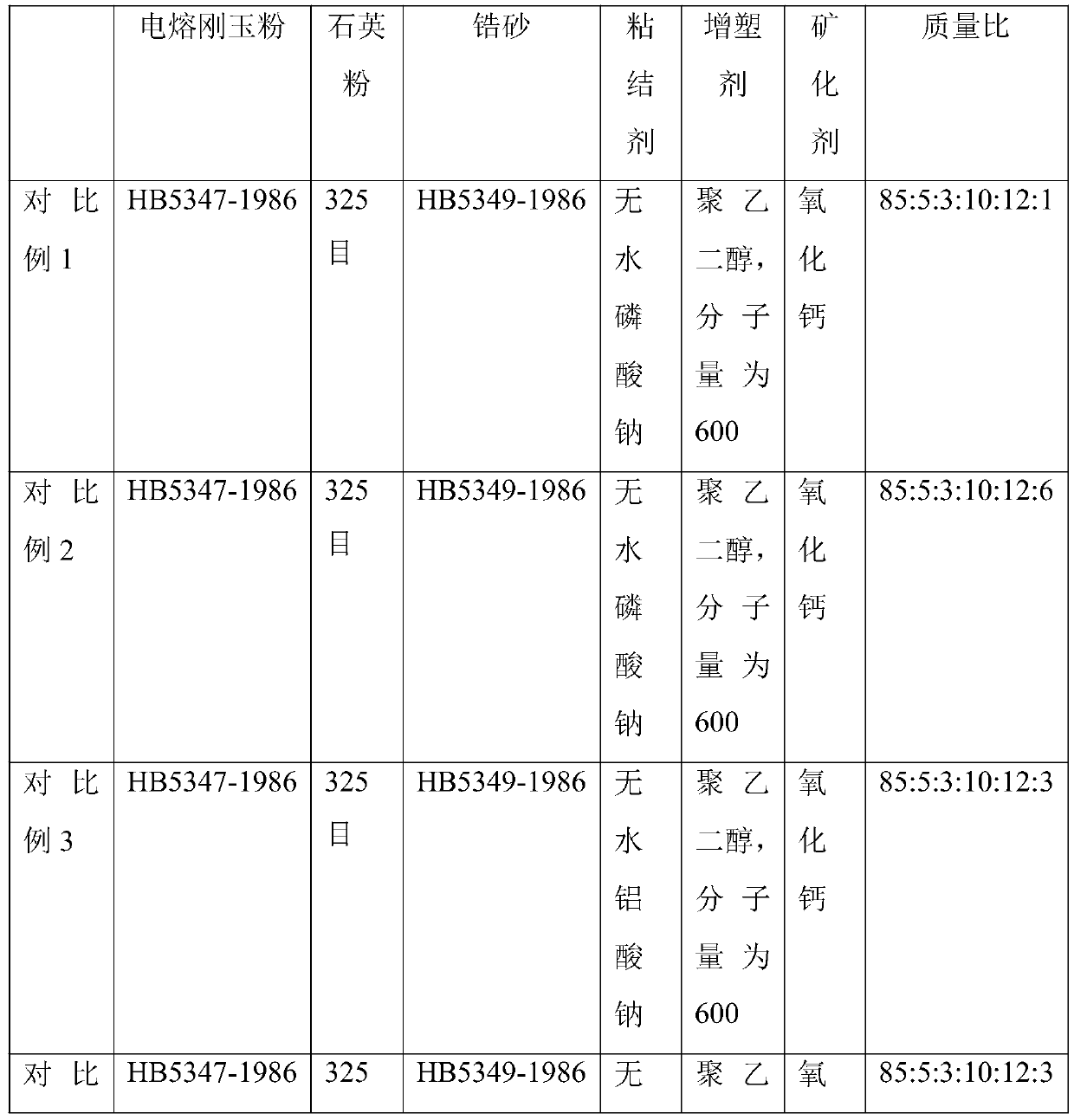

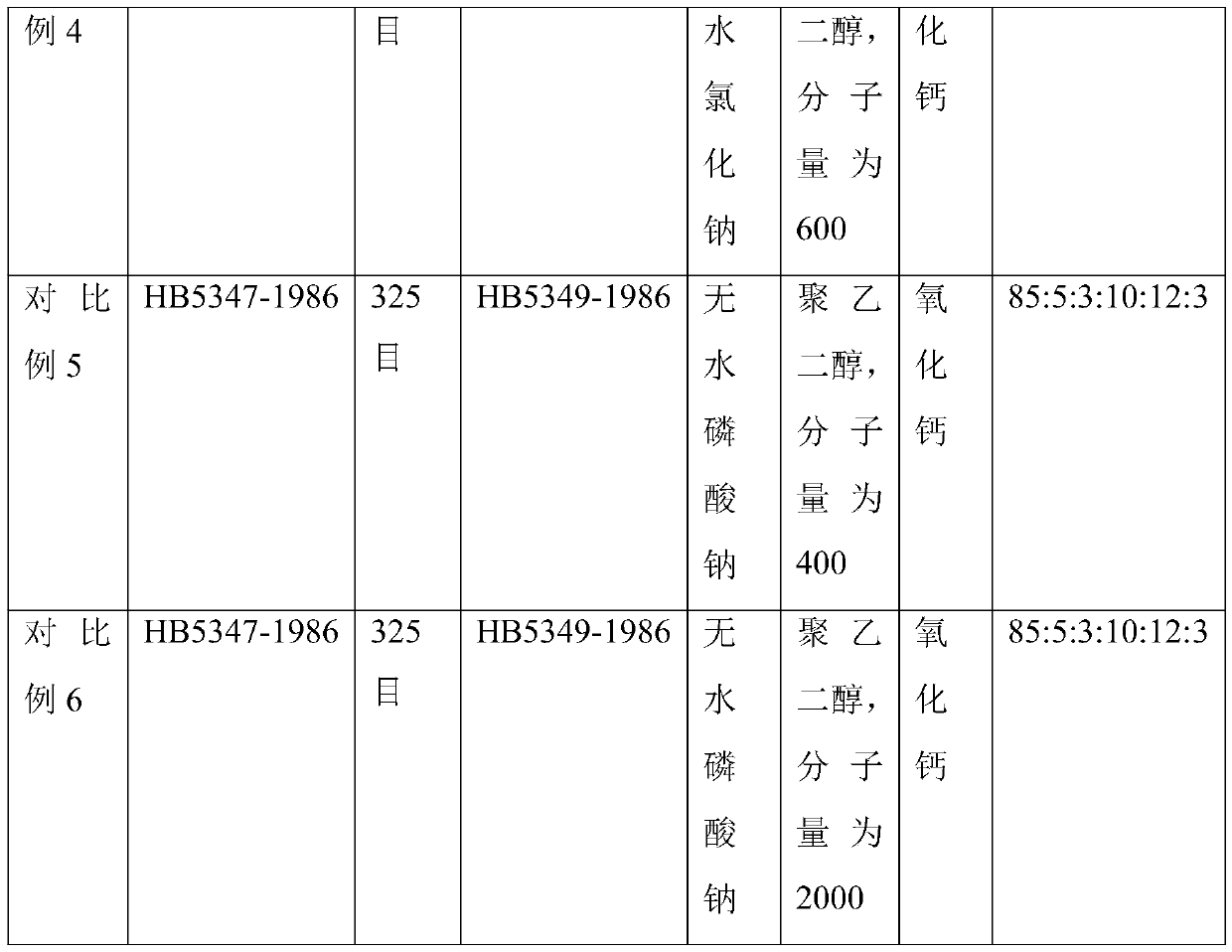

[0034] The raw materials and proportions of the soluble ceramic mold are: fused corundum powder, quartz powder, zircon sand, binder (anhydrous sodium phosphate), plasticizer (polyethylene glycol, molecular weight 600), mineralizer ( Calcium oxide) mass ratio is 85:5:3:10:12:3.

[0035] The soluble ceramic mold is prepared by pressing and sintering, the sintering pressure is 1.0MPa, the sintering temperature is 1673K, and the sintering time is 30min.

[0036] The surface of the prepared soluble ceramic mold is smooth, and its apparent bulk density is 3.0g / cm 3 , moderate shrinkage, small deformation, the three-p...

Embodiment 2

[0047] Follow the steps below to prepare SiC 3D / ZL202 composite material.

[0048] S1. According to the prepared SiC 3D / ZL202 composite material shape design mold, preparation of soluble ceramic mold;

[0049] Soluble ceramic mold raw materials and their proportions are: fused corundum powder, quartz powder, zircon sand, binder (anhydrous sodium phosphate), plasticizer (polyethylene glycol, molecular weight 600), mineralizer (oxidizer Calcium) mass ratio is 85:5:3:10:12:3.

[0050] The soluble ceramic mold is prepared by pressing sintering method, the sintering pressure is 1.0MPa, the sintering temperature is 1573K, and the sintering time is 30min.

[0051] The surface of the prepared soluble ceramic mold is smooth, and its apparent bulk density is 3.0g / cm 3 , moderate shrinkage, small deformation, the three-point bending strength of the tested soluble ceramic mold is 22MPa, which can meet the requirements of the vacuum pressure positive pressure infiltration method.

...

Embodiment 3

[0062] Follow the steps below to prepare SiC 3D / ZL101 composite material.

[0063] S1. Design a mold according to the external dimensions of the prepared composite material, and prepare a soluble ceramic mold.

[0064] Soluble ceramic mold raw materials and their proportions are: fused corundum powder, quartz powder, zircon sand, binder (anhydrous sodium phosphate), plasticizer (polyethylene glycol, molecular weight 600), mineralizer (oxidizer Calcium) mass ratio is 85:5:3:10:12:3.

[0065] The soluble ceramic mold is prepared by pressing and sintering, the sintering pressure is 3MPa, the sintering temperature is 1673K, and the sintering time is 40min.

[0066] The prepared soluble ceramic mold has a smooth surface, an apparent bulk density of 3.2g / cm3, moderate shrinkage, and small deformation. The tested three-point bending strength of the soluble ceramic mold is 31.5MPa, which can meet the requirements of vacuum pressure and positive pressure impregnation. legal needs. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com