Winding die for molding interior grid stiffened cylindrical shell structure part and using step

A technology for cylindrical shells and parts, applied in applications, household appliances, household components, etc., can solve the problems of poor surface finish, unstable rib size, difficult demoulding, etc., and achieve good product quality consistency and difficult solutions Difficulty in pressurization and demoulding, effects of high dimensional accuracy and positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

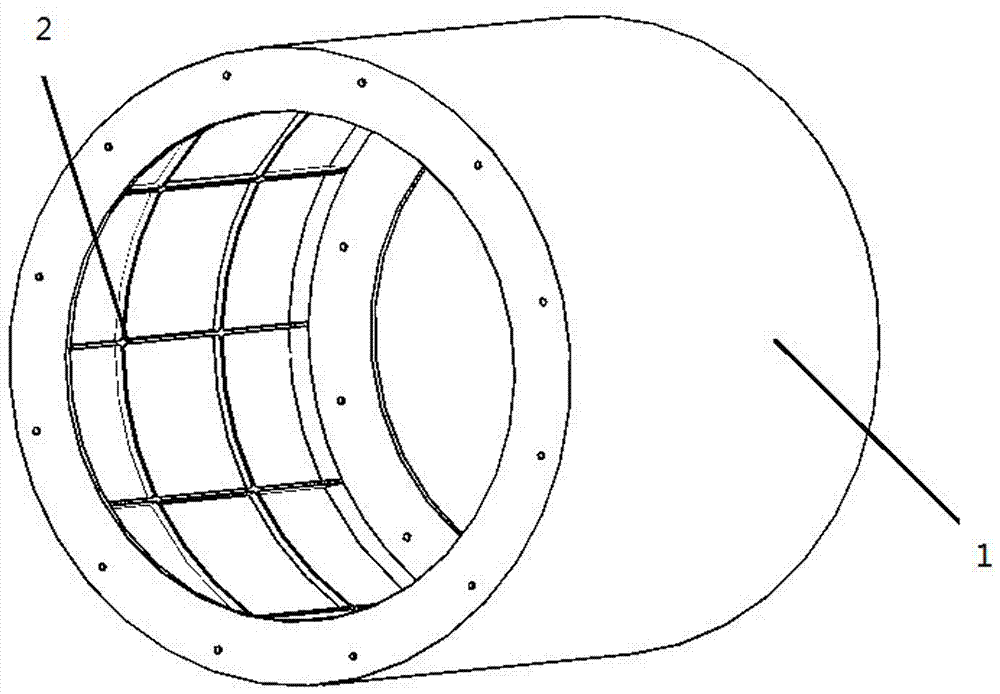

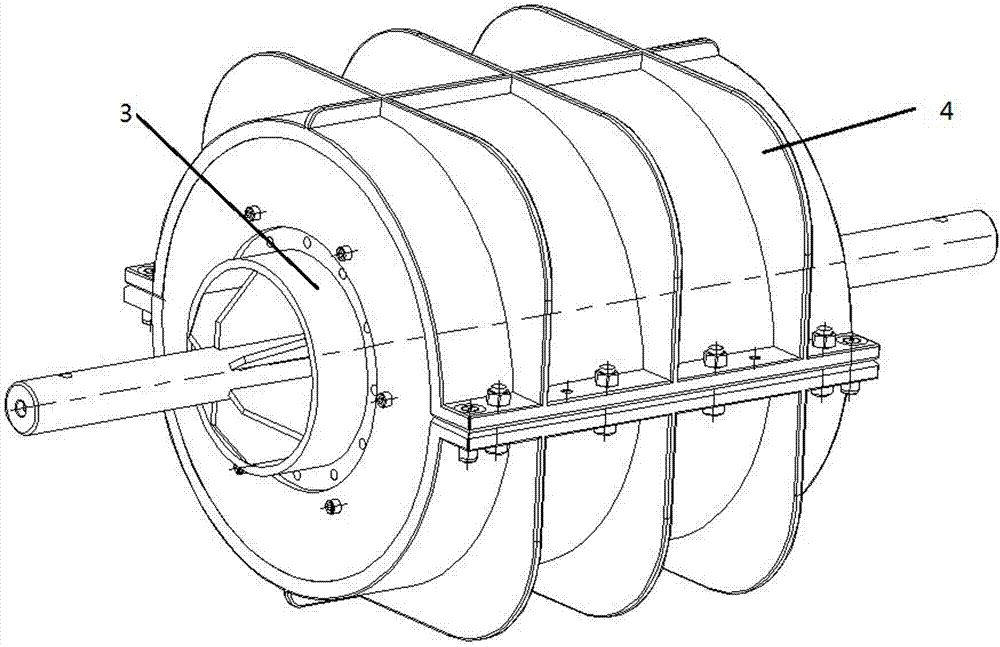

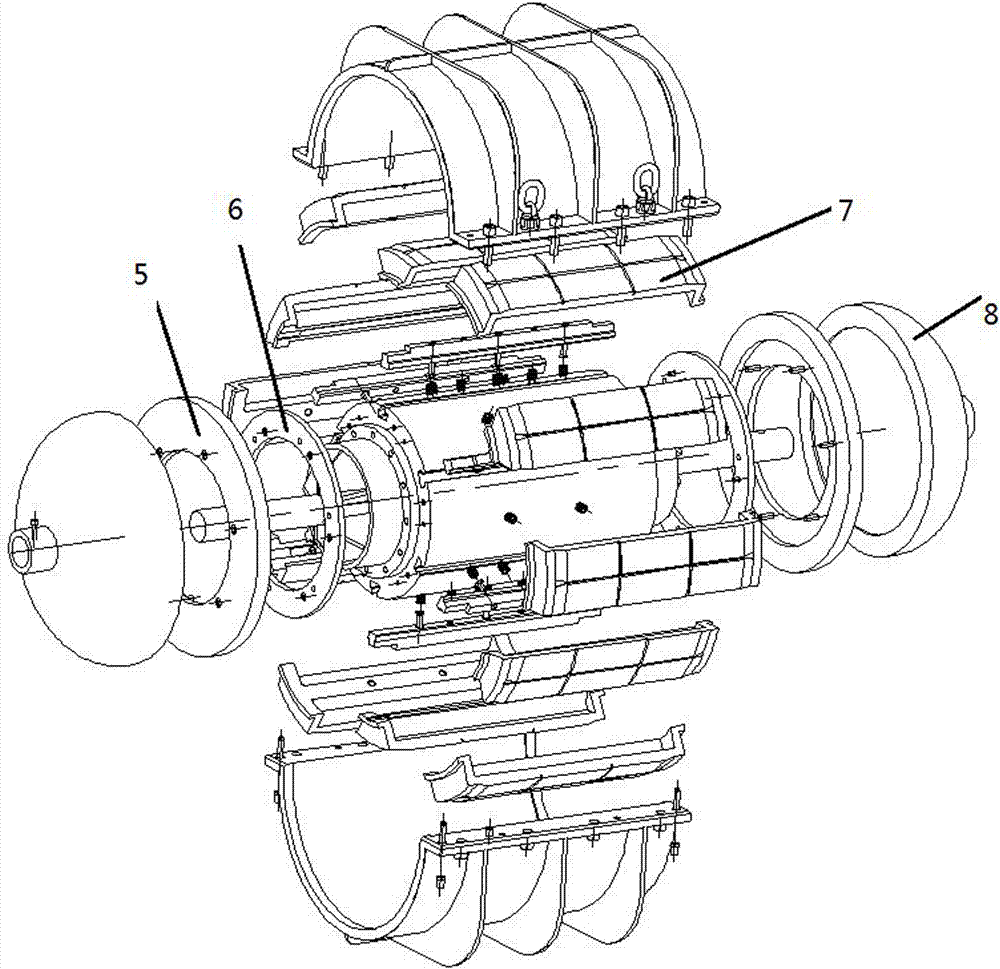

[0025] The present invention is a kind of winding mold for molding inner grid reinforced cylindrical shell structure parts, such as figure 2 , image 3 , including a main body mold 3, a core mold 7, a positioning ring 6, an end frame flange 5, a head 8 and an outer mold 4, the above-mentioned main mold 3 is a steel mold, the core mold 7 is an aluminum mold, and the rest are all steel mold, such as Figure 4 As shown, the mandrel 7 is divided into several petals in the longitudinal direction, such as Figure 4 As shown, a T-shaped block is installed on the split core mold 7, which is assembled with the T-shaped slot 9 provided on the main body mold 3.

[0026] The use process of the mold is as follows: first clean the mold, assemble the mold, then wind the prepreg tape of the reinforcing rib through the winding machine, put the air felt and other vacuum bags for pre-compaction; repeat the above operation until the rib is wound Finished; then pave the skin prepreg, move the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com