Preparation method of large-depth special-shaped curved-surface aluminum alloy box-like piece and mold of piece

A special-shaped surface, aluminum alloy technology, applied in the field of precision sheet metal processing, can solve the problems of part thinning, part accuracy and quality influence, uneven wall thickness distribution, etc., to improve dimensional accuracy and profile accuracy, forming equipment requirements The effect of low, wall thickness uniformity advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

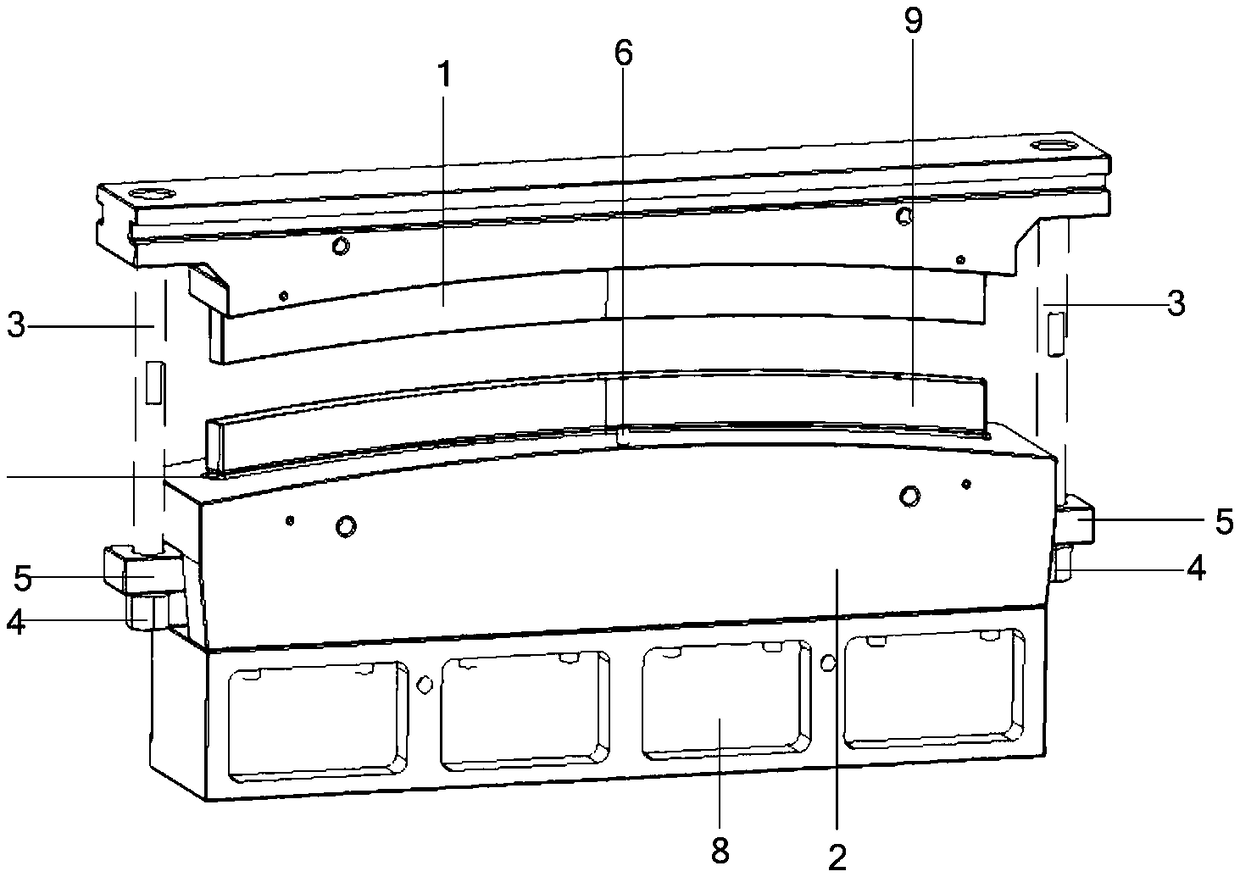

[0023] refer to figure 1 , shows a schematic structural view of a large-depth special-shaped curved surface aluminum alloy box-shaped piece mold provided by an embodiment of the present invention. The large-depth special-shaped curved surface aluminum alloy box-shaped piece mold includes a punch 1, a concave mold 2, two tie rods 3, Two limit nuts 4, a positioning pin 6 and a base 8.

[0024] Wherein, one end of the die 2 is fixedly connected to the base 8, and the other end is provided with a cavity 9 with openings at both ends of the blank, and the two ends of the die 2 close to the base 8 are provided with a top plate 5 accommodated in the cavity 9 , the two ends of the ejector plate 5 protrude from the die 2, and the two ends of the ejector plate 5 protrude from the die are provided with corresponding first screw through holes (not shown in the figure), the first screw through holes The pores are open at both ends.

[0025] One end of the punch 1 far away from the die 2 i...

Embodiment 2

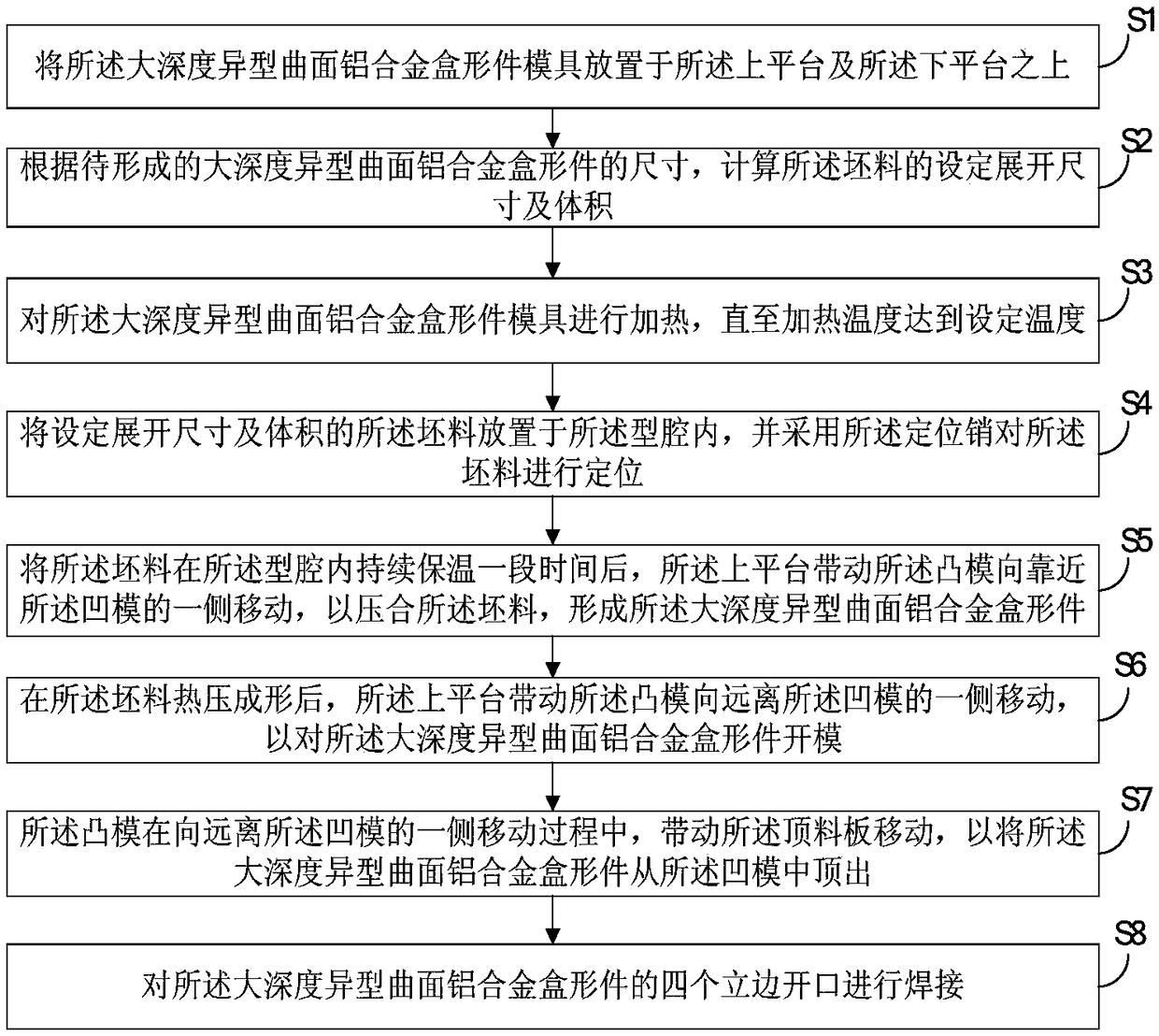

[0032] refer to figure 2 , which shows a method for preparing a large-depth special-shaped curved aluminum alloy box-shaped part provided by the embodiment of the present invention, including the mold of the large-depth special-shaped curved surface aluminum alloy box-shaped part of the above-mentioned embodiment, the blank, and the upper part of the thermoforming machine Platform and lower platform, described preparation method specifically can comprise the following steps:

[0033] Step S1: placing the large-depth special-shaped curved aluminum alloy box mold on the upper platform and the lower platform.

[0034] In the embodiment of the present invention, the large-depth special-shaped curved surface aluminum alloy box mold can be made of 45# steel, and when preparing a large-depth special-shaped curved surface aluminum alloy box-shaped piece, the large-depth special-shaped curved surface aluminum The piece mold is placed on the upper and lower platforms of the thermoform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com