Hydraulic expansion assembled combination die for quenching ferrules

A combined mold and assembled technology, applied in quenching devices, manufacturing tools, furnace types, etc., can solve the problems of no assembly and combined structure, large proportion of mold investment, larger than production site, etc., to solve the problem of demolding difficulties, The effect of stable quenching quality and easy correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

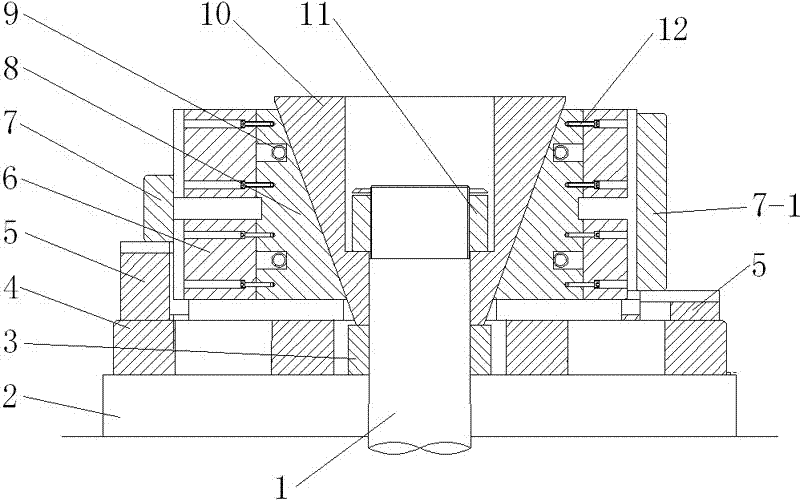

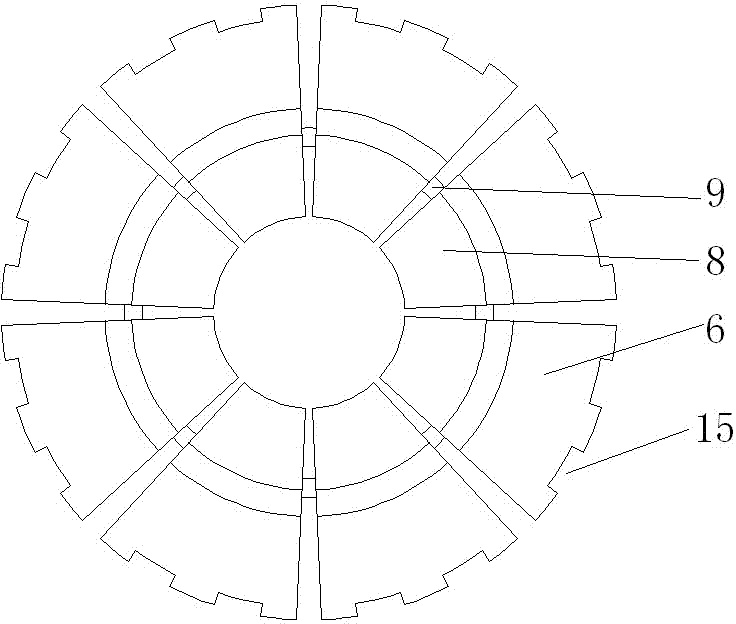

[0015] like figure 1 , 3 As shown, a quenching disc 4 is installed on the quenching workbench 2, and a mold seat 5 is installed on the quenching disc. The cylinder piston rod 1 is fixedly connected with the core cone 10 through the fixed nut 11, and the quenching work block is evenly distributed on the outer cone surface of the core cone, and the quenching work block is wrapped on the outer cone surface of the core cone by the ring tension spring 9 superior. The quenching working block is composed of a female cone block 8 and a working block 6 fixed on the female cone block by fixing screws 12. Cooperate with the outer arc surface of the work block, and have a longitudinal groove 15 on the outer arc surface where the work block is in contact with the quenched workpiece.

[0016] During quenching, the piston rod 1 of the oil cylinder moves upward, and under the action of the annular tension spring 9, the quenching work block radially contracts. According to the inner dia...

Embodiment 2

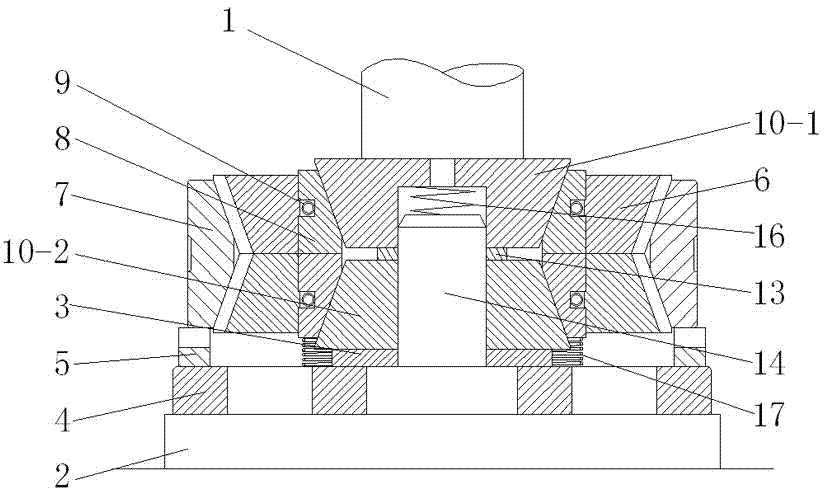

[0021] like figure 2 , 3 As shown, when the inner hole of the workpiece is two cone surfaces, such as the outer ring of a double-row tapered roller bearing, the cone 10 in the center can be used to meet the needs of the quenched part. Two cones with two small heads facing each other can be used. The composed core cone, the lower cone 10-2 and the upper cone 10-1 are set on the guide mandrel 14, and the guide mandrel is fixedly installed on the quenching workbench 2, and the upper end surface of the upper cone and the guide mandrel An upper compression spring 16 is installed between them, and the quenching work block installed on the outer cone surface of the two cones is composed of the female cone block 8 and the work block 6 fixed on the female cone block by fixing screws, the inner cone block of the female cone block The arc surface matches the outer cone surfaces of the two cones, and the working block matches the outer arc surface of the female cone block. A longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com