UV (Ultraviolet) cured glue composition, soft mold and transfer printing method

A technology for curing glue and composition, applied in the directions of copying/marking methods, printing, adhesives, etc., can solve problems such as poor demoulding, and achieve the effect of easy separation and solving difficulty in demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

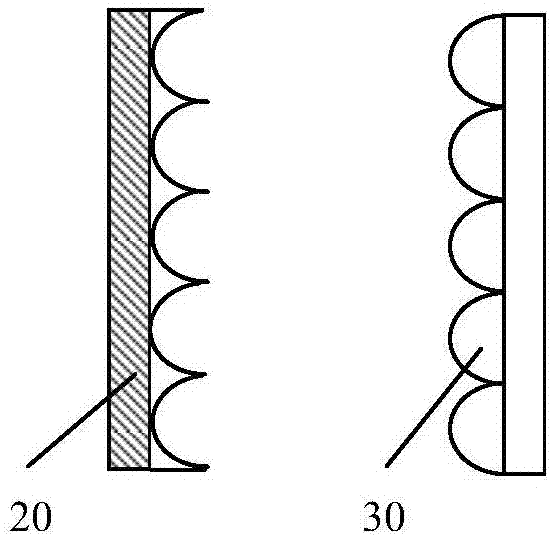

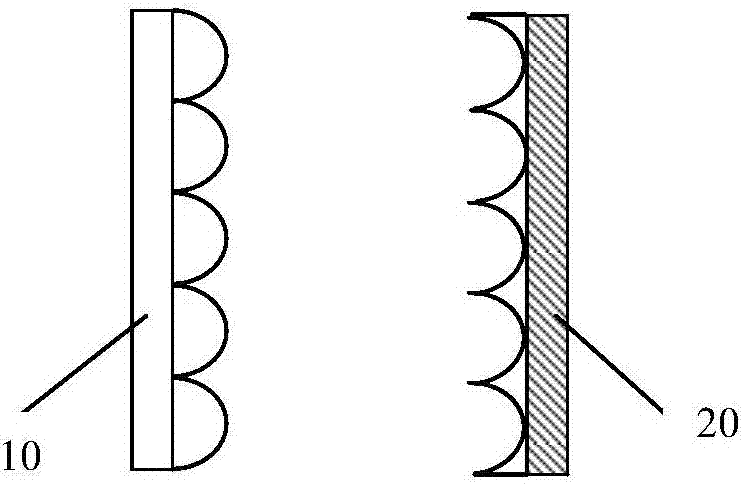

[0045] In another preferred embodiment of the present application, a method for preparing a soft mold is provided, that is, preferably, the above-mentioned step S1 includes: setting a mixture formed of a UV-curable adhesive composition on the metal mold 10; setting a soft substrate on the mixture , and the soft substrate is rolled; the mixture after the roll is solidified to obtain a cured layer; and the metal mold is removed, and the cured layer is subjected to UV curing to obtain a soft mold 20 (reference figure 2 ).

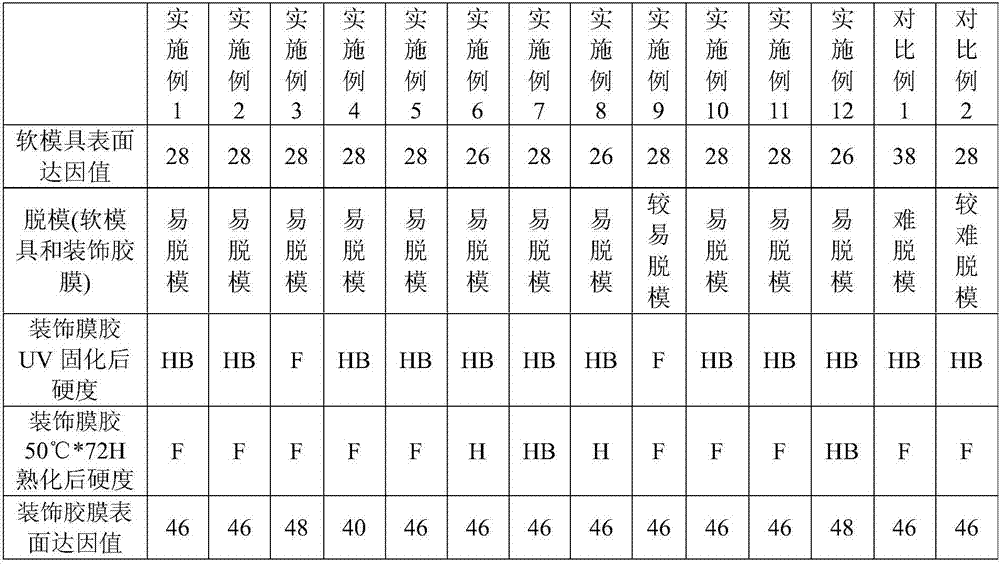

[0046] By curing first and then curing, the hardness and surface dyne value of the soft template can be flexibly controlled. For example, in order to control the surface dyne value 2 . In addition, the above-mentioned surface dyne value is also conducive to improving the stain resistance of the soft mold. On the one hand, after strong UV curing, the soft film glue can fully react, so that it can reach a higher hardness, and the surface structure is not easil...

Embodiment 1

[0054] Preparation of decorative film

[0055] (1) 20 parts of urethane acrylate EO-2238, 10 parts of urethane acrylate 6158B-80, 15 parts of silicon modified resin SIU2400, 20 parts of monomer EM214, 30 parts of monomer EM221, 4 parts of initiator 184, 1 part The auxiliary agent BYK-UV3505 was mixed and stirred for 30 minutes to obtain the master rubber.

[0056] (2) 40 parts of urethane acrylate EB8210, 10 parts of urethane acrylate XP2765, 17 parts of pure acrylate 353L, 10 parts of monomer EM39, 15 parts of monomer EM214, 4 parts of initiator 184, 1 part of initiator TPO, 3 parts of 1 part additive BYK-3560 was mixed and stirred for 30 minutes to obtain decorative film glue.

[0057] (3) Choose PET with a thickness of 188 μm as the soft base material, set the master mold glue on the metal mold, set the soft base material on the master mold glue, and roll the soft base material with rollers to make the master mold glue uniform; Use ultraviolet light to cure the master mol...

Embodiment 2

[0060] Preparation of decorative film

[0061] (1) 20 parts of urethane acrylate EO-2238, 10 parts of urethane acrylate 6158B-80, 15 parts of silicon modified resin SIU2400, 20 parts of monomer EM214, 30 parts of monomer EM221, 4 parts of initiator 184, 1 part The auxiliary agent BYK-UV3505 was mixed and stirred for 30 minutes to obtain the master rubber.

[0062] (2) 40 parts of urethane acrylate EB8210, 10 parts of urethane acrylate XP2765, 17 parts of pure acrylate 353L, 10 parts of monomer EM39, 15 parts of monomer EM214, 4 parts of initiator 184, 1 part of initiator TPO, 3 parts of 1 part additive BYK-3560 was mixed and stirred for 30 minutes to obtain decorative film glue.

[0063] (3) Choose PET with a thickness of 188 μm as the soft base material, set the master mold glue on the metal mold, set the soft base material on the master mold glue, and roll the soft base material with rollers to make the master mold glue uniform; Use ultraviolet light to cure the master mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com