Combined multi-cavity forming die of expansion type foaming brick

A technology for forming molds and foam bricks, which is applied in ceramic molding machines, mold auxiliary parts, manufacturing tools, etc., can solve the problems of difficult demoulding and demoulding of expanded foam bricks, and improve production efficiency and product quality. , The effect of reducing production cycle and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

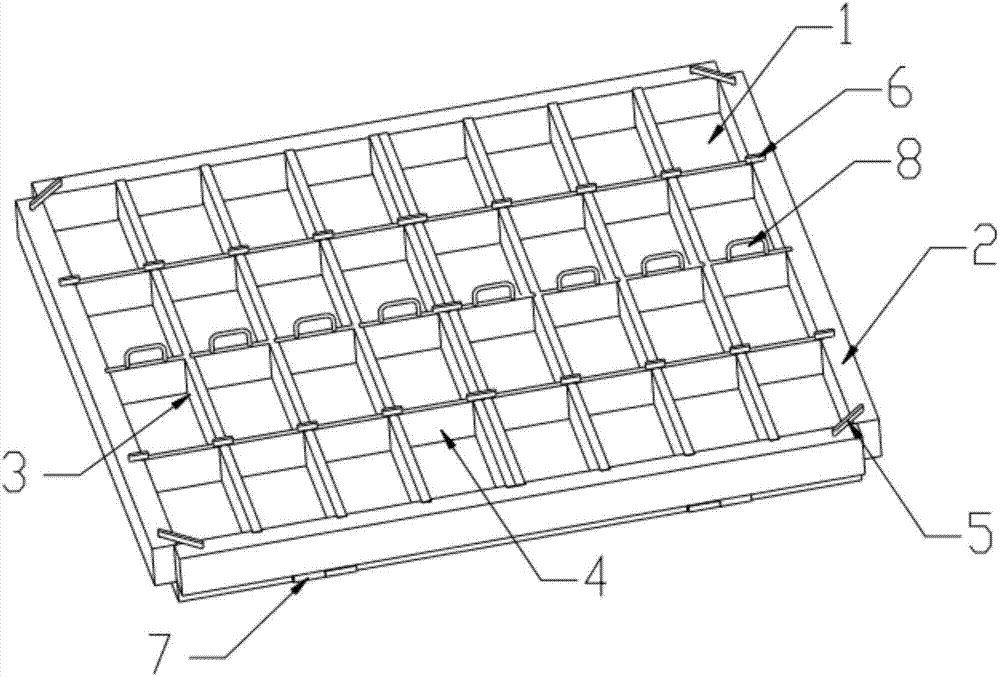

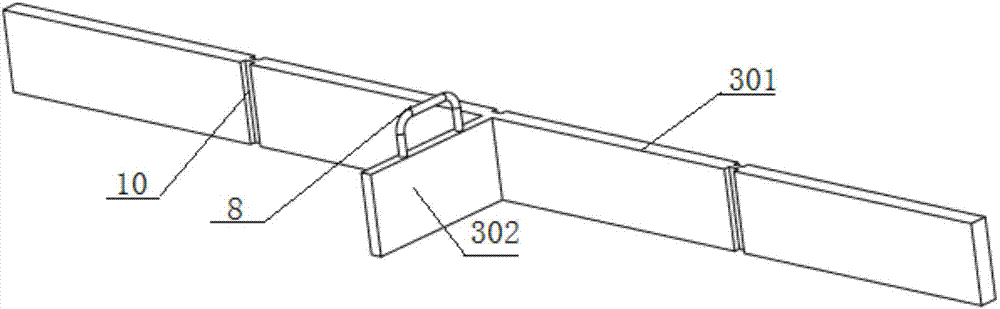

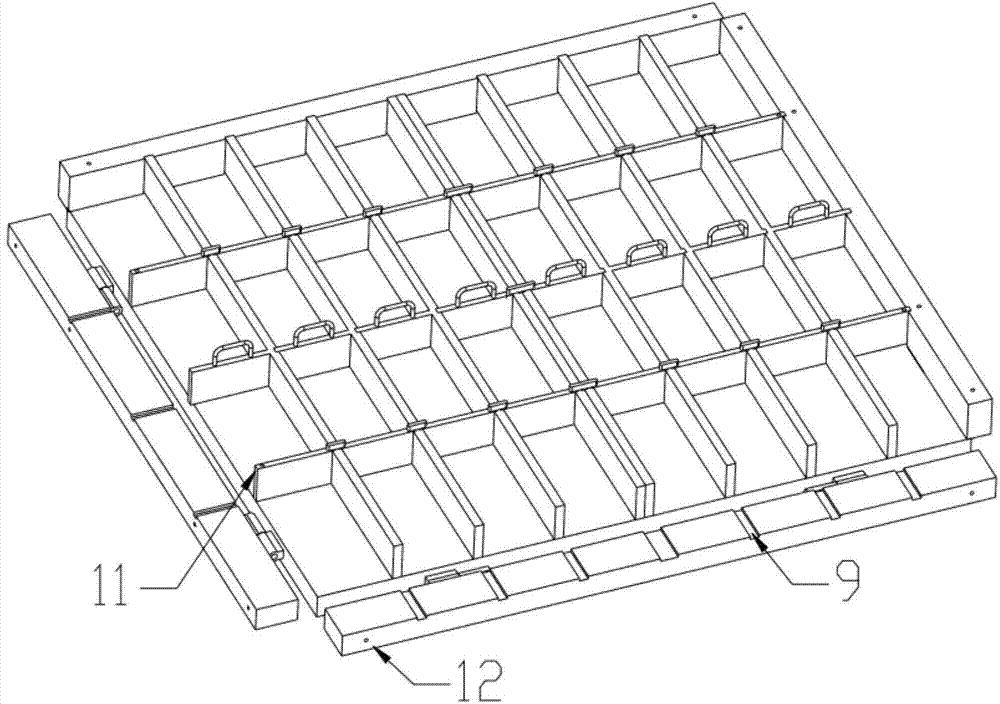

[0023] Such as figure 1 As shown, a combined multi-cavity molding die for expansion foam bricks includes: a mold bottom plate 1, a plurality of mold side plates 2, a plurality of long partition templates 3 and a plurality of short partition templates 4, and the plurality of molds The side plates 2 are respectively connected to the sides of the mold bottom plate 1 through hinges 7. At this time, various methods such as plugging and riveting can also be used to jointly enclose the periphery of the combined multi-cavity molding mould; when the mold side plates 2 pass through the hinges 7 When turning to the vertical state, the lower bottom surface of the mold side plate 2 is closely attached to the upper surface of the mold bottom plate 1, and the adjacent mold side plates 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com