Polyurethane condom producing process

A manufacturing method and technology for condoms, which can be applied in coating and other directions, can solve problems such as low efficiency, and achieve the effects of complete process, high production efficiency and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

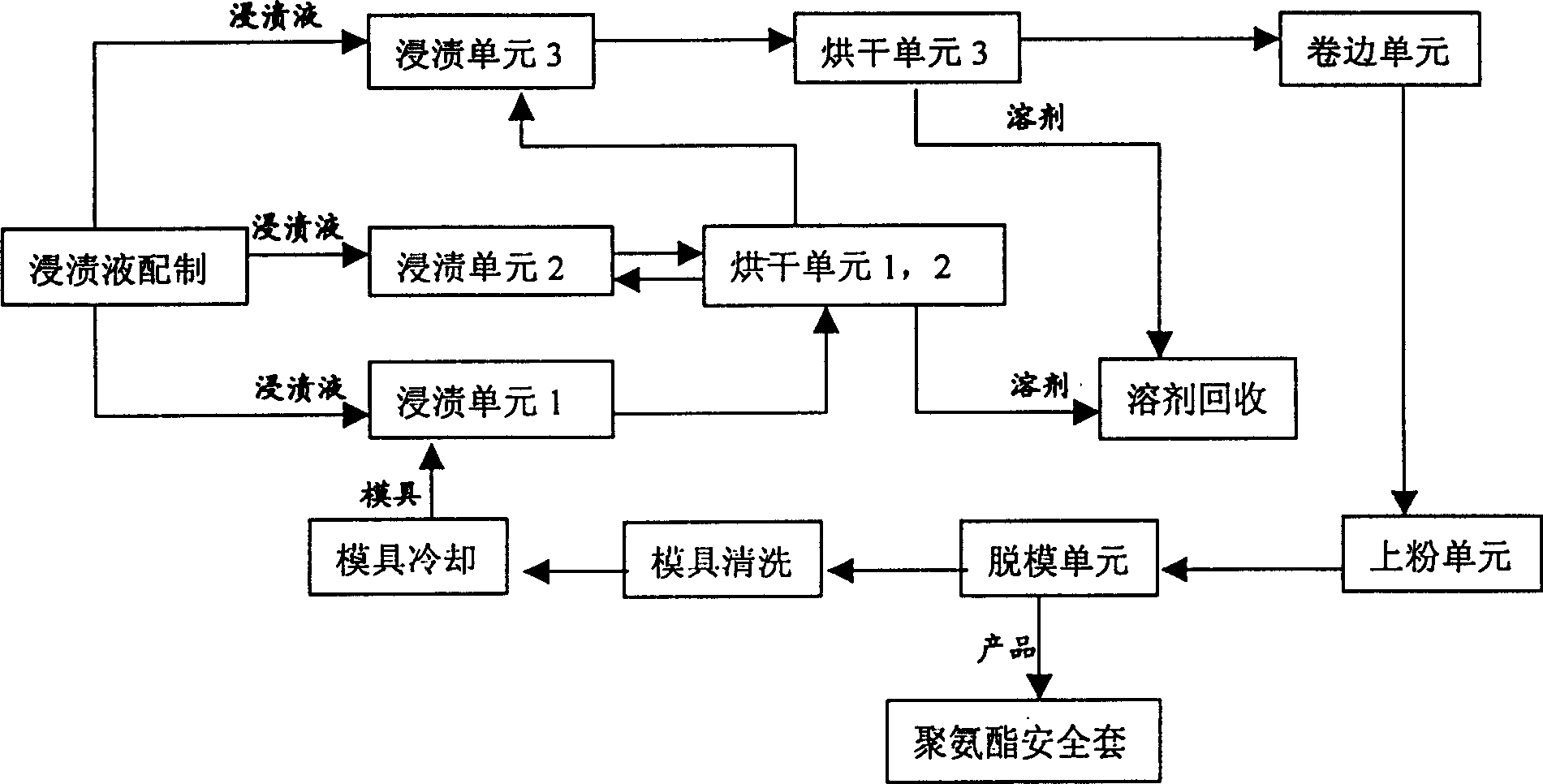

[0036] The technological process of the embodiment of the present invention is as figure 1As shown, it includes mold passivation treatment, mold cleaning, mold drying and cooling, dipping solution preparation, dipping molding, drying, curling, powdering, demoulding and other processes. It should be noted that: 1. The mold passivation treatment is done before the mold is used for the first time. Two, because the embodiments of the present invention all adopt dip molding and drying each three times, so there are three dip molding units; and drying is because the mold shares a drying unit after dip molding 1 and 2 units, so there are two drying units. 3. The solvent evaporated from the drying unit can be recovered through the solvent recovery process. Each process flow is carried out in the direction indicated by the arrow in the figure.

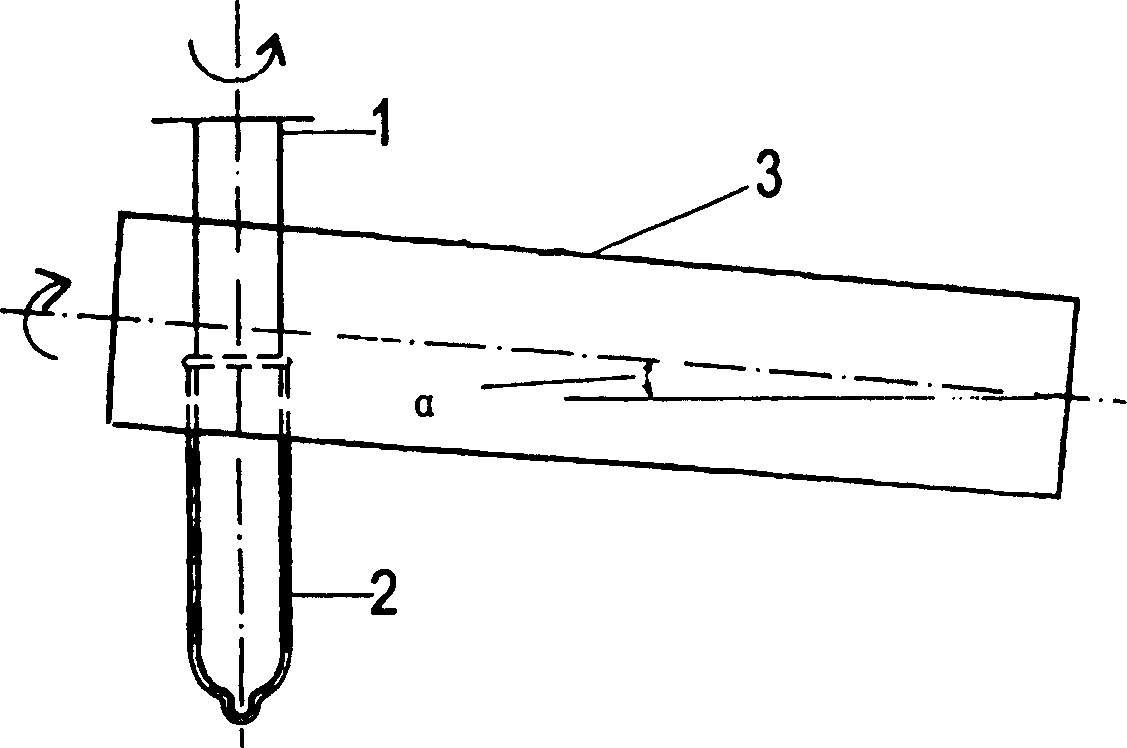

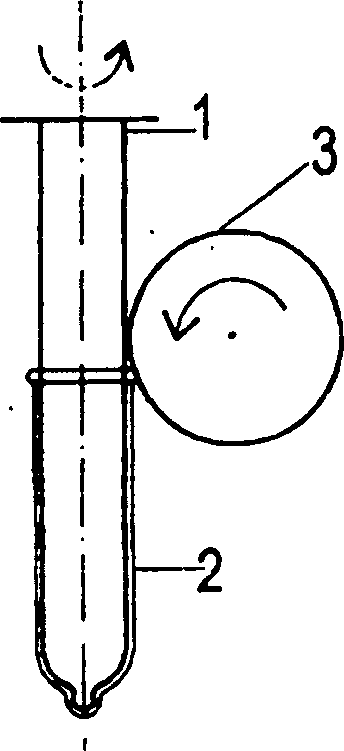

[0037] The principle of the curling process is shown in figure 2 , 3 , among the figure 1 is a mould, 2 is a polyurethane condom, and 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com