Core-shell type adsorbing material and preparation method thereof

An adsorption material, core-shell type technology, applied in the field of core-shell type adsorption material and its preparation, can solve the problems of reduced service life, weak force of porous adsorption material and binder, easy pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

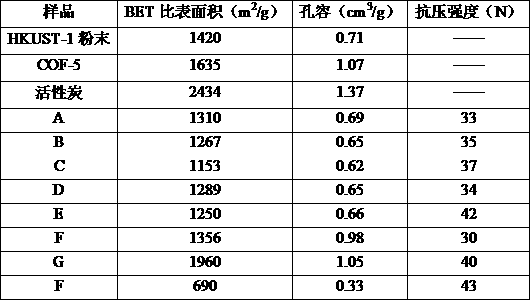

Embodiment 1

[0040] Weigh 100 g HKUST-1 and 5 g carboxymethyl cellulose into a beaker, mix them evenly with a resonance mixer, pour them into a beaker filled with 500 mL of water, stir mechanically for 10 min, and transfer to a 500 mL portion In the liquid funnel, drop it into the Dewar bottle filled with liquid nitrogen at a rate of 30 drops / min. After dropping, take out the particles at the bottom of the Dewar bottle with a plastic colander, put it in a freeze-drying box, and dry it at -20 °C. 12 h, after cooling down, place the molded body in a beaker filled with saturated sodium silicate and immerse it, take it out after 10 seconds and put it in a 20 wt% sulfuric acid solution, take it out after 10 seconds, age at 20 °C for 10 h, wash with water, After immersing in 0.1 wt% ammonia water for 10 h, it was dried at 100 °C for 12 h to obtain core-shell adsorption material A. In core-shell adsorption material A, the weight ratio of HKUST-1, binder and silica gel calculated as silica is 1:0....

Embodiment 2

[0042]Weigh 100 g HKUST-1 and 10 g carboxymethyl cellulose into a beaker, mix them evenly with a resonance mixer, pour them into a beaker filled with 500 mL of water, stir mechanically for 10 min, and transfer to a 500 mL portion In the liquid funnel, drop it into the Dewar bottle filled with liquid nitrogen at a rate of 30 drops / min. After dropping, take out the particles at the bottom of the Dewar bottle with a plastic colander, put it in a freeze-drying box, and dry it at -20 °C. After cooling down for 12 h, place the molded body in a beaker filled with saturated sodium silicate and immerse it, take it out after 10 seconds and place it in a 20 wt% sulfuric acid solution, then take it out after 10 seconds and age it at 20°C for 10 h, wash it with water, and put it in The core-shell adsorption material B was obtained after soaking in 0.1 wt% ammonia water for 10 h and then drying at 100 °C for 12 h. In the core-shell adsorption material B, the weight ratio of HKUST-1, binder ...

Embodiment 3

[0044] Weigh 100 g HKUST-1 and 15 g carboxymethyl cellulose into a beaker, mix them evenly with a resonance mixer, pour them into a beaker filled with 500 mL of water, stir mechanically for 10 min, and transfer to a 500 mL portion In the liquid funnel, drop it into the Dewar bottle filled with liquid nitrogen at a rate of 30 drops / min. After dropping, take out the particles at the bottom of the Dewar bottle with a plastic colander, put it in a freeze-drying box, and dry it at -20 °C. After cooling down for 12 h, the molded body was immersed in a beaker filled with saturated sodium silicate, taken out after 10 seconds and placed in a 20 wt% sulfuric acid solution, and aged at 20 °C for 10 hours after 10 seconds, washed with water, and placed in a After immersing in 0.1 wt% ammonia water for 10 h, it was dried at 100 °C for 12 h to obtain core-shell adsorption material C. In the core-shell adsorption material C, the weight ratio of HKUST-1, binder and silica gel calculated as si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com