Manufacturing method for unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam

A manufacturing method and carbon fiber technology, which are applied in the manufacturing field of UAV carbon fiber beams, can solve the problems of low yield of airbag core film, narrow application range, complex process, etc., and achieve stable size, wide application range and simplified molding tooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] refer to Figure 1 to Figure 6 :

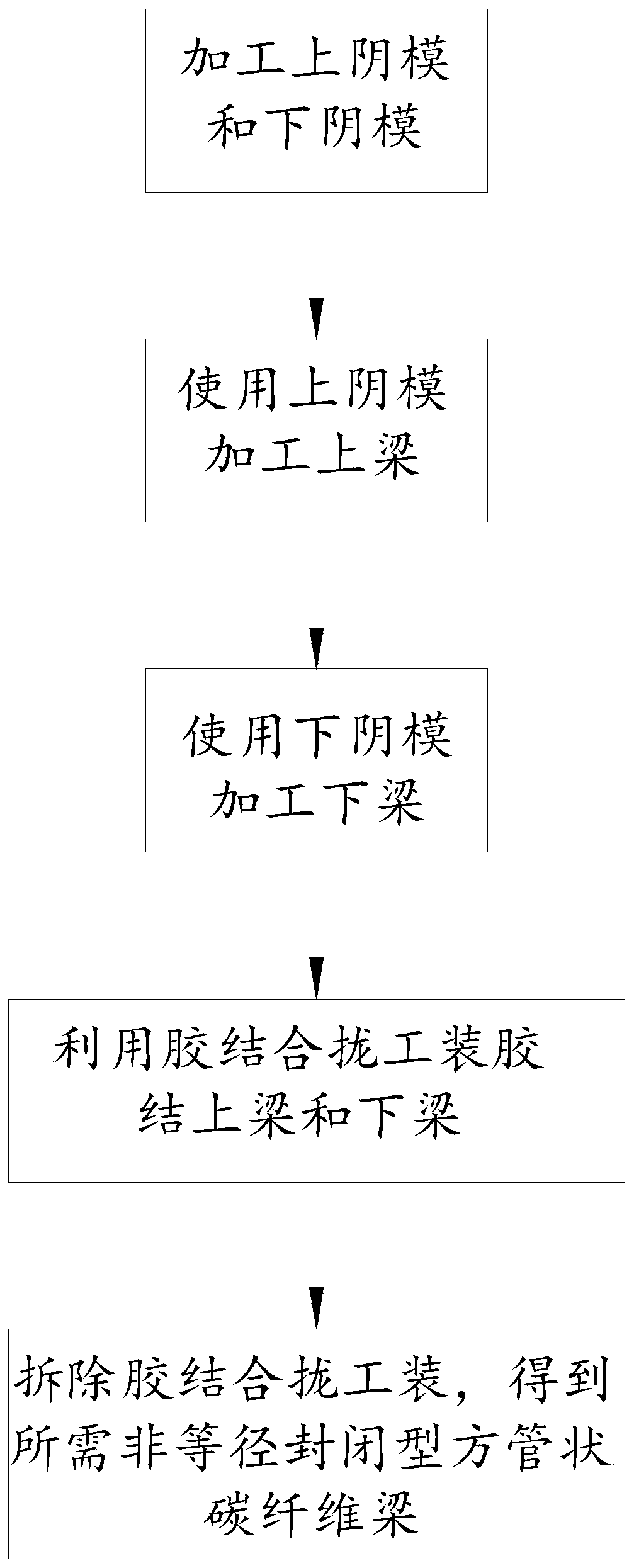

[0048] A method for manufacturing a non-equal diameter closed square tubular carbon fiber beam of an unmanned aerial vehicle, comprising the following steps:

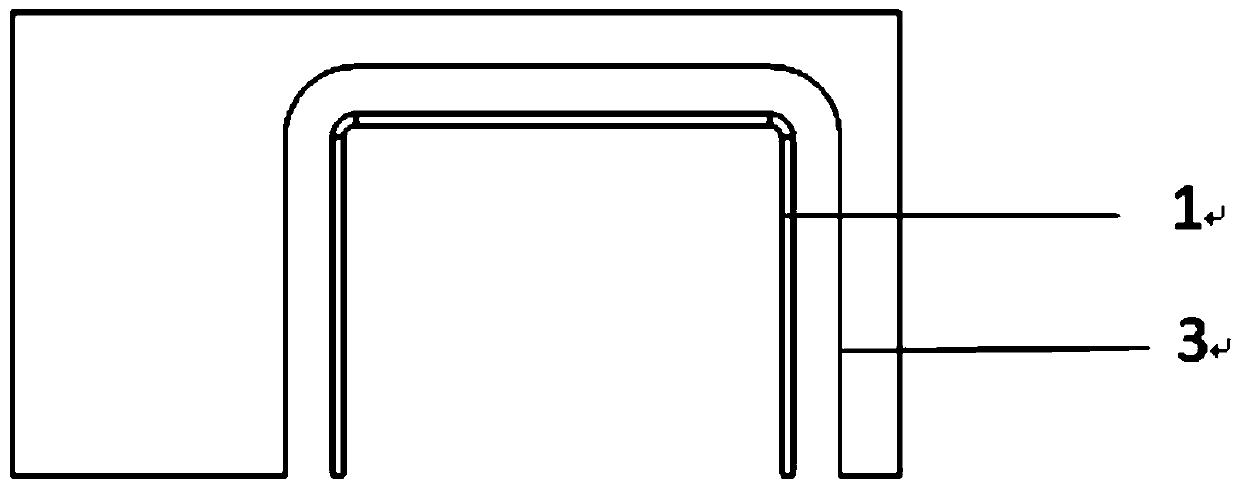

[0049] Step 1) Processing upper female mold 3 and lower female mold 4:

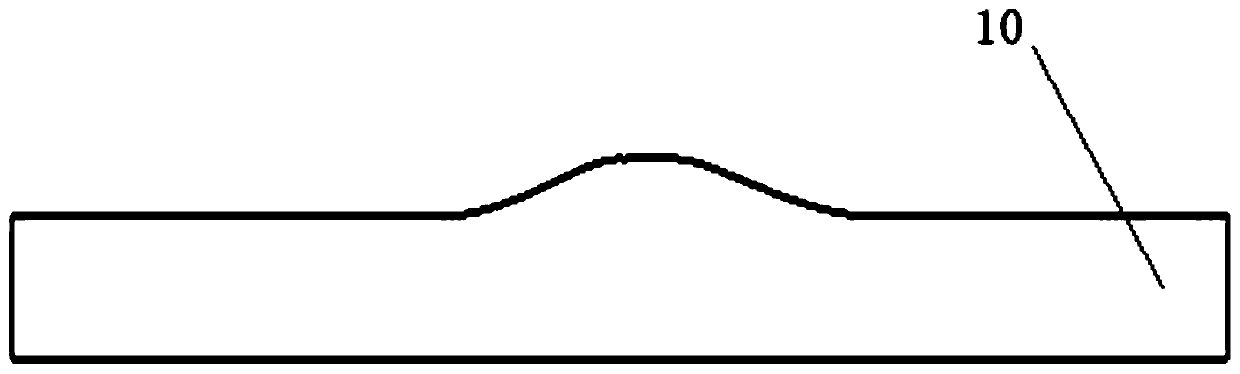

[0050] CATIA software is used to optimize the design of the non-equal diameter closed square tubular carbon fiber beam 10 that needs to be processed, divide it into upper beam 1 and lower beam 2, and make corresponding beams according to the divided upper beam 1 and lower beam 2. Upper female mold 3 and lower female mold 4, both ends of upper female mold 3 and lower female mold 4 lengthwise are open type.

[0051] Step 2) Use the upper female mold 3 to process the upper beam 1:

[0052] Clean the upper female mold 3 and apply a release agent, then spread the carbon fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com