Liquid expansion forming device and liquid expansion forming process

A molding device and molding process technology, which is applied in the field of liquid expansion molding device, can solve the problems of large force on the molding mold and high requirements on the molding mold, and achieve the effects of low mold requirements, improved precision, and reduced working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

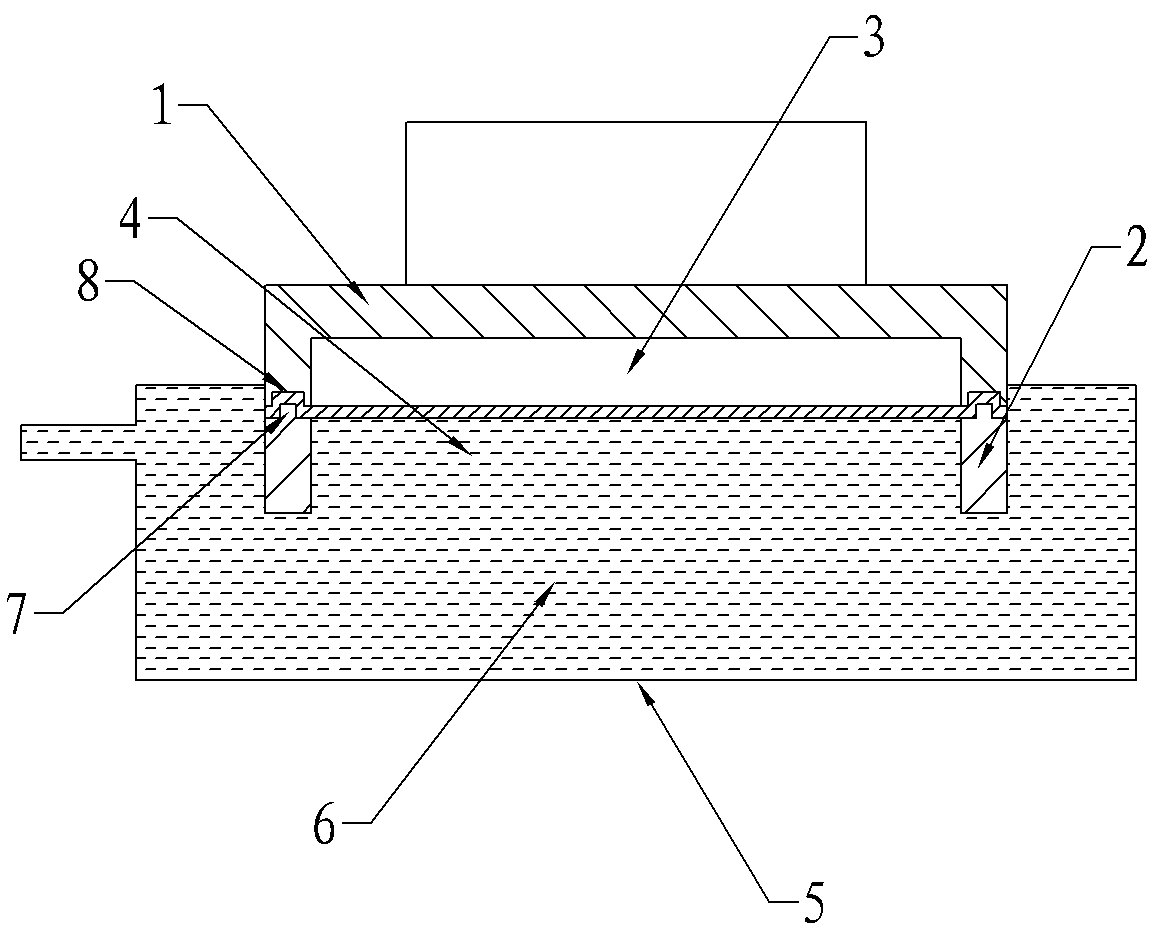

[0018] refer to figure 1 , liquid expansion molding device, including a pre-tightening pressure mold 1 and a floating pressure mold 2, the pre-tightening pressure mold 1 is provided with a molding cavity 3, and the middle part of the floating pressure mold 2 is provided with a through hole 4 adapted to the molding cavity 3 , the floating pressure die 2 is installed in the liquid expansion pressure chamber 5; the edge of the formed plate is pressed by the joint surface of the floating pressure die 2 and the pre-tightening pressure die 1; the pre-tightening pressure die 1 is connected with the press, and the liquid expansion pressure chamber 5 Connect the high-pressure liquid 6; when forming, the press drives the pre-tightening pressure die 1 to cooperate with the floating pressure die 2 to press and seal the edge of the forming plate, and the liquid expansion pressure chamber 5 inputs the high-pressure liquid 6, and the high-pressure liquid 6 pairs with the floating pressure die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com