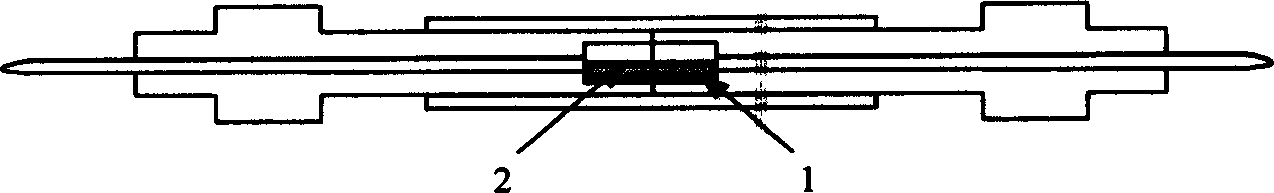

Forming method of zirconium oxide ceramic insertion needle for fibre-optic connector and its equipment

A technology of zirconia ceramics and optical fiber connectors, which is applied in the coupling of optical waveguides, etc., can solve the problems of inability to use automatic operation, and achieve the effect of low requirements for molds and equipment and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix 1000 grams of deionized water, 160 grams of acrylamide, and 4 grams of N,N'-methylenebisacrylamide to prepare a premix. 100 grams of zirconia powder was used as a raw material, mixed with 40 ml of premixed solution, and ball milled for 24 hours to obtain a low-viscosity (<1 Pa·s) zirconia ceramic slurry. Add an appropriate amount of catalyst tetramethylethylenediamine and initiator ammonium persulfate into the slurry, mix well and pour into the feed tank; turn the feed handle to feed slowly, keep the pressure for 2 minutes, and wait for the slurry to solidify for another 7 minutes After demoulding, the inner hole diameter of the green body is 0.136mm measured after drying, and sintered at 1500°C for 2 hours, and the measured inner hole diameter is 0.121mm, which meets the accuracy requirements of the pin green body. After the green body is processed by a precision grinding machine, the dimensional accuracy and various basic properties of the obtained pin products me...

Embodiment 2

[0050] 1000 grams of deionized water, 250 grams of methacrylamide, and 6.25 grams of dipropylene tartaric acid diamide were mixed to prepare a premix. 100 grams of zirconia powder was used as a raw material, mixed with 35 ml of premixed solution, and ball milled for 20 hours to obtain a low-viscosity (<1 Pa·s) zirconia ceramic slurry. Add an appropriate amount of initiator hydrogen peroxide to the slurry, mix it evenly and pour it into the feed tank; turn the feed handle to feed slowly, keep the pressure for 3 minutes, and then demould after the slurry is solidified for another 5 minutes, and measure the green body after drying The diameter of the inner hole is 0.138mm. After sintering at 1520°C for 2 hours, the measured diameter of the inner hole is 0.119mm, which meets the precision requirements of the pin body.

Embodiment 3

[0052] 1000 grams of deionized water, 110 grams of methacrylic acid, and 8 grams of polydimethylacrylic acid were prepared into a premix. 100 grams of zirconia powder was used as a raw material, mixed with 50 ml of premixed solution, and ball milled for 48 hours to obtain a low viscosity (<1 Pa·s) zirconia ceramic slurry. Add an appropriate amount of initiator azo hydrochloride to the slurry, mix it evenly, and pour it into the feeding tank; turn the feeding handle to feed slowly, keep the pressure for 2 minutes, and then release the mold after the slurry is solidified for another 8 minutes, and the green body is dried The diameter of the inner hole was measured to be 0.135mm, and the diameter of the inner hole was measured to be 0.117mm after sintering at 1550°C for 2 hours, which met the accuracy requirements of the pin body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com