Construction method of tunnel waterproof and water drainage system

A construction method and technology for waterproofing and drainage, which can be used in drainage, tunnels, tunnel linings, etc., can solve the problems of manual hanging, water leakage at welding, and labor-intensive workers, so as to improve construction efficiency, reduce labor intensity, and prevent waterproofing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A construction method for a tunnel waterproof and drainage system, comprising the following steps:

[0014] (1) Raw materials for preparing the drainage layer: add 50 parts of rubber particles with a particle diameter of 1.0 mm, 50 parts of rubber particles with a particle diameter of 100 mesh, 20 parts of mineral wool fibers, and 50 parts of VAE emulsion in parts by weight and mix and stir evenly;

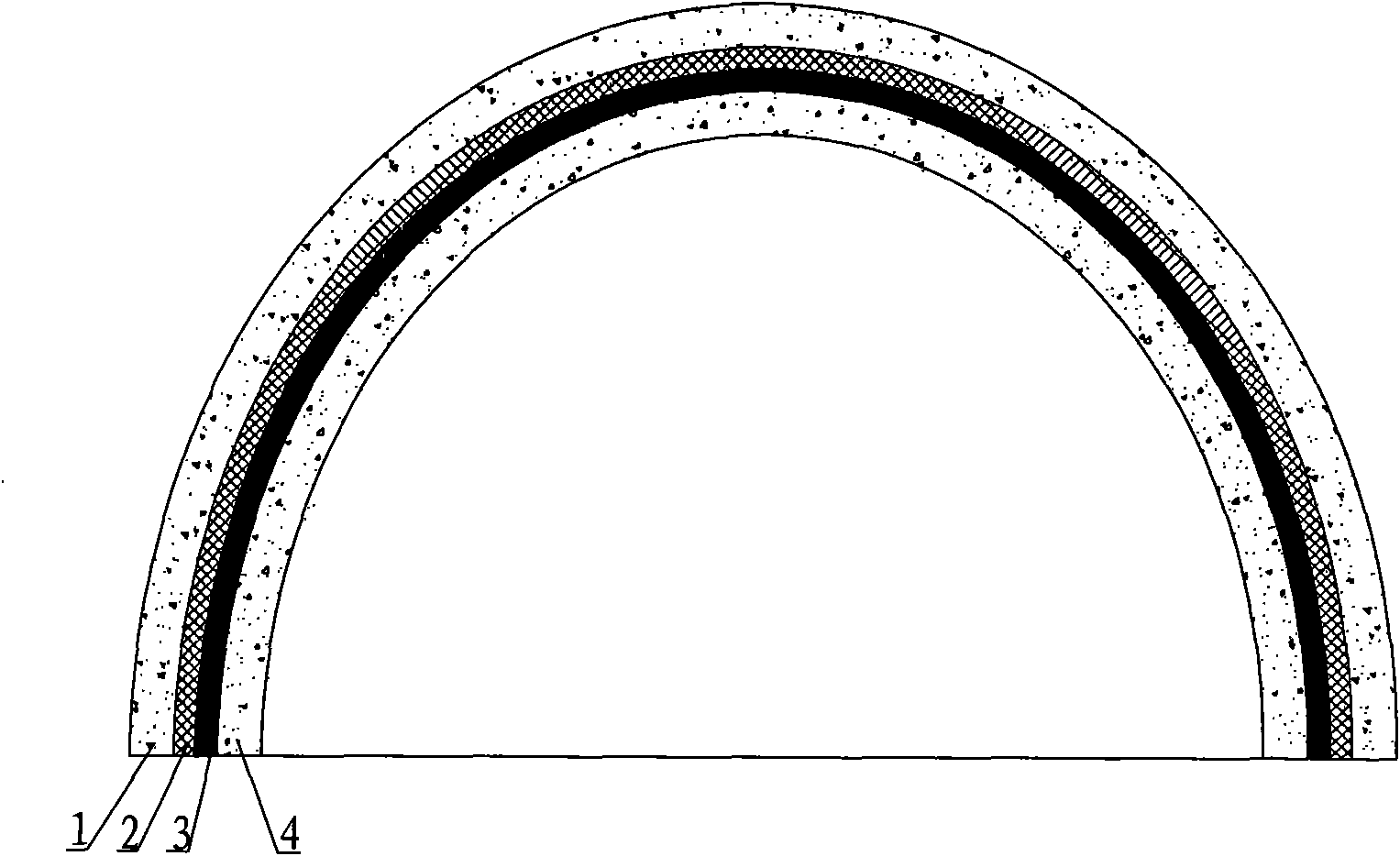

[0015] (2) Spray drainage layer 2: Put the prepared drainage layer raw materials into the sprayer and spray evenly on the shotcrete base 1 on the inner wall of the tunnel (the shotcrete base is sprayed on the inner surface of the rock layer on the inner wall of the tunnel). Until the pits on the base layer are filled up, and air-dried naturally to obtain the drainage layer 2;

[0016] (3) Spray waterproof layer 3: Add isocyanate and amine compounds to different containers in the special polyurea spray machine, mix and spray on the drainage layer with a spray thickness of 1....

Embodiment 2

[0018] A construction method for a tunnel waterproof and drainage system, comprising the following steps:

[0019] (1) Prepare drainage layer raw materials: add 75 parts of rubber particles with a particle diameter of 1.5 mm, 25 parts of rubber particles with a particle diameter of 200 mesh, 20 parts of mineral wool fibers, and 80 parts of VAE emulsion in parts by weight and mix and stir evenly;

[0020] (2) Spray drainage layer 2: Put the prepared drainage layer raw materials into the sprayer and spray evenly on the shotcrete base 1 on the inner wall of the tunnel (the shotcrete base is sprayed on the inner surface of the rock layer on the inner wall of the tunnel). Until the pits on the base layer are filled up, and air-dried naturally to obtain the drainage layer 2;

[0021] (3) Spray waterproof layer 3: Add isocyanate and amine compounds to different containers in the special polyurea spray machine, mix and spray on the drainage layer with a spray thickness of 1.5mm, and i...

Embodiment 3

[0023] A construction method for a tunnel waterproof and drainage system, comprising the following steps:

[0024] (1) Preparation of drainage layer raw materials: add 25 parts of rubber particles with a particle diameter of 1.2 mm, 75 parts of rubber particles with a particle diameter of 150 mesh, 30 parts of mineral wool fibers, and 60 parts of VAE emulsion in parts by weight and mix and stir evenly;

[0025] (2) Spray drainage layer 2: Put the prepared drainage layer raw materials into the jetting machine and spray evenly on the shotcrete base layer on the inner wall of the tunnel 1, (the shotcrete base layer is sprayed on the inner surface of the rock layer on the inner wall of the tunnel). Until the pits on the base layer are filled up, and air-dried naturally to obtain the drainage layer 2;

[0026] (3) Spray waterproof layer 3: Add isocyanate and amine compounds to different containers in the special polyurea spray machine, mix and spray on the drainage layer with a spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com