Friction extrusion method for preparing aluminium silicon alloy section bar

A technology of aluminum-silicon alloy and extrusion method, which is applied in the field of metal forming processing, can solve the problems of high equipment and mold requirements and difficult material forming, achieve low equipment and mold requirements, eliminate casting defects, and have a good silicon phase refinement effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

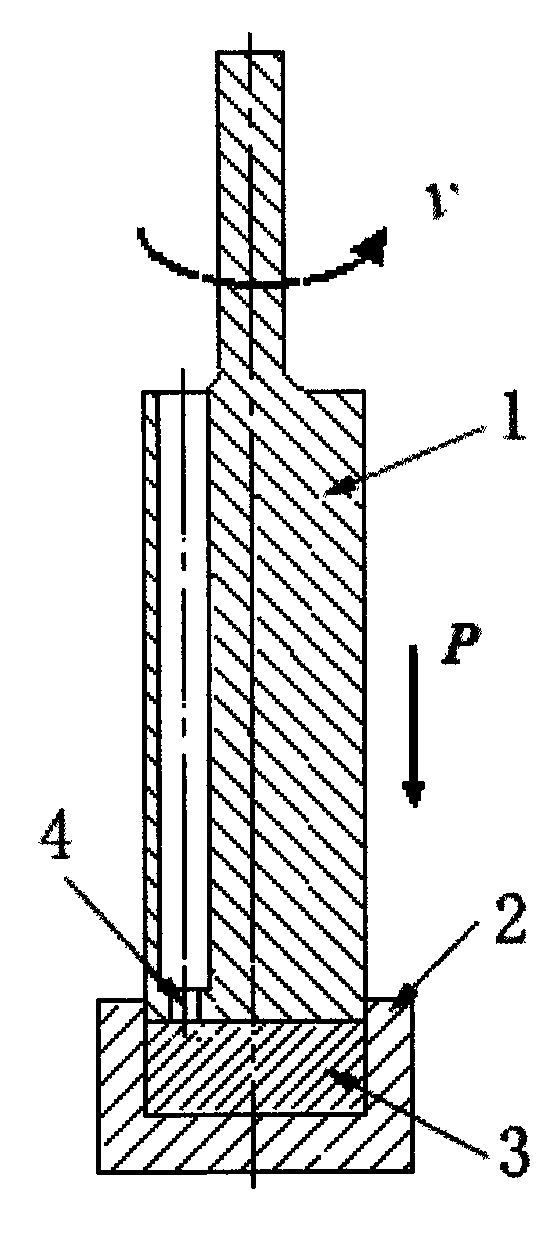

[0018] Friction extrusion processing of Al-30% Si alloy:

[0019] A. Manufacture a friction extrusion head with Φ4 eccentric hole;

[0020] B. The friction extrusion head rubs against the surface of the Al-30% Si alloy billet, and the friction relative speed reaches 530 revolutions per minute. At the same time, an extrusion force of 5 MPa is applied to extrude a Φ4 profile from the eccentric hole of the friction extrusion head, wherein The average diameter of silicon phase particles reaches 1.3 microns.

Embodiment 2

[0022] Friction extrusion processing of Al-12% Si alloy:

[0023] A. Manufacture a friction extrusion head with Φ4 eccentric hole;

[0024] B. The friction extrusion head rubs against the surface of the Al-12% Si alloy billet, and the friction relative speed reaches 530 revolutions per minute. At the same time, an extrusion force of 5 MPa is applied to extrude a Φ4 profile from the eccentric hole of the friction extrusion head, wherein The average diameter of silicon phase particles reaches 1.0 micron.

Embodiment 3

[0026] Friction extrusion processing of Al-6%Si alloy:

[0027] A. Manufacture a friction extrusion head with Φ4 eccentric hole;

[0028] B. The friction extrusion head rubs against the surface of the Al-6% Si alloy billet, and the friction relative speed reaches 530 revolutions per minute. At the same time, an extrusion force of 5 MPa is applied to extrude a Φ4 profile from the eccentric hole of the friction extrusion head, wherein The average diameter of silicon phase particles reaches 0.9 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com