Method for maintaining pressures and then quickly boosting pressures for metal low-pressure casting molding of aluminum alloy automobile chassis castings

A technology of low-pressure casting and automobile chassis, which is applied in the field of rapid pressurization after pressure-holding for the metal mold of aluminum alloy automobile chassis castings. Production requirements, avoiding spills and splashes, and the effect of low-cost mass production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

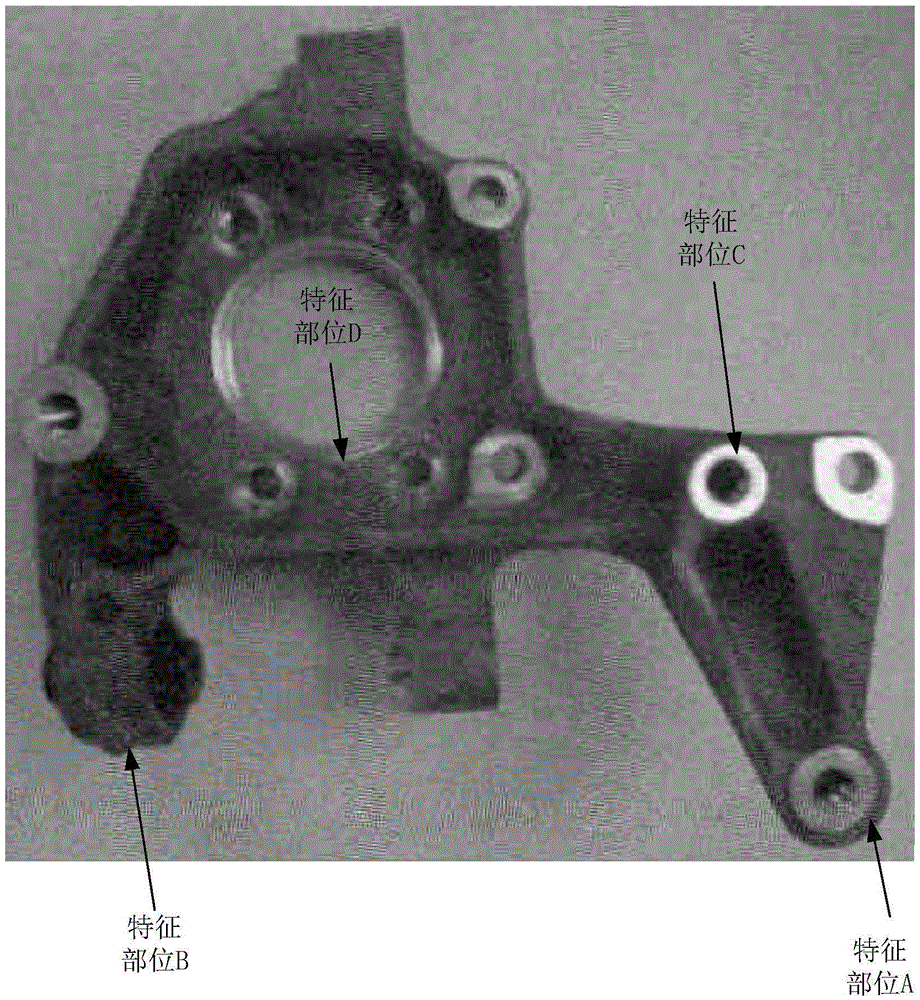

[0065] The rear steering knuckle of the car is made of A356 alloy and weighs 2.8kg. The pouring temperature is 710°C, the mold material is H13 steel, the initial mold temperature is 350°C, and the cooling method is a combination of 9-way water cooling and 3-way air cooling. Steering knuckle configuration and characteristic parts such as Figure 1A shown. Figure 1A The structure refers to "Lightweight Design and Test Verification of Automobile Rear Steering Knuckle" of Hyundai Manufacturing Engineering, No. 4, 2014, author Zhang Qi et al.

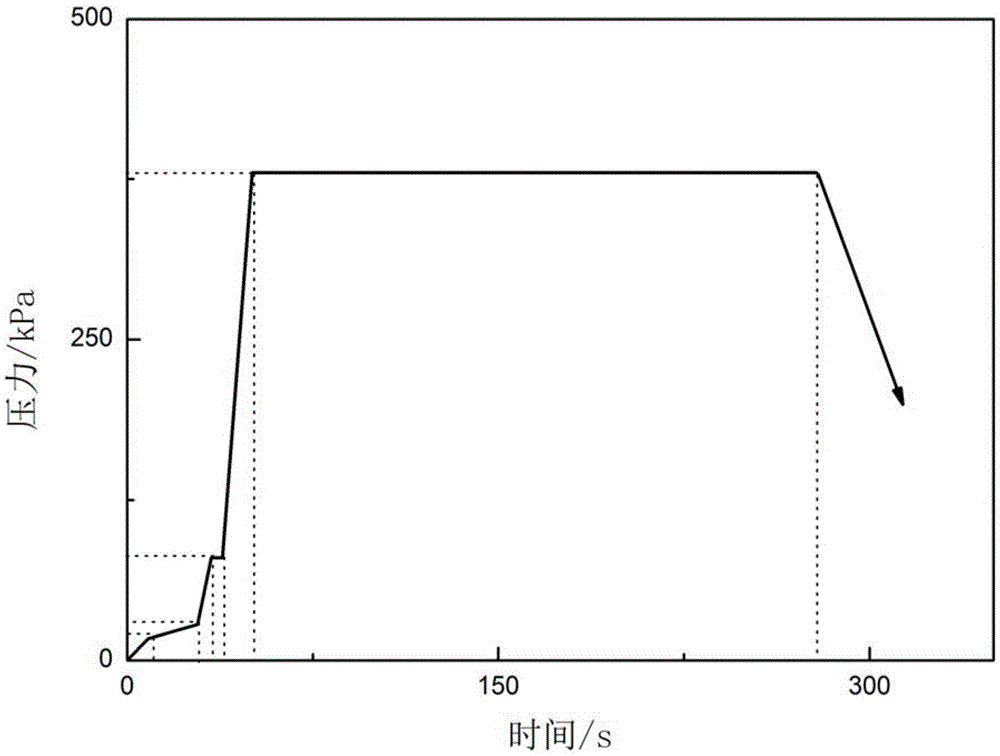

[0066] see Figure 1B As shown in the pressure-time curve diagram of the rapid pressurization method after holding the pressure, the steps for preparing aluminum alloy automobile chassis castings by using the metal mold low-pressure casting molding and using the rapid pressurization method after holding the pressure are as follows:

[0067] Step 1, liquid ascending stage;

[0068] Under the conditions of the liquid lifting pressure of 17k...

Embodiment 2

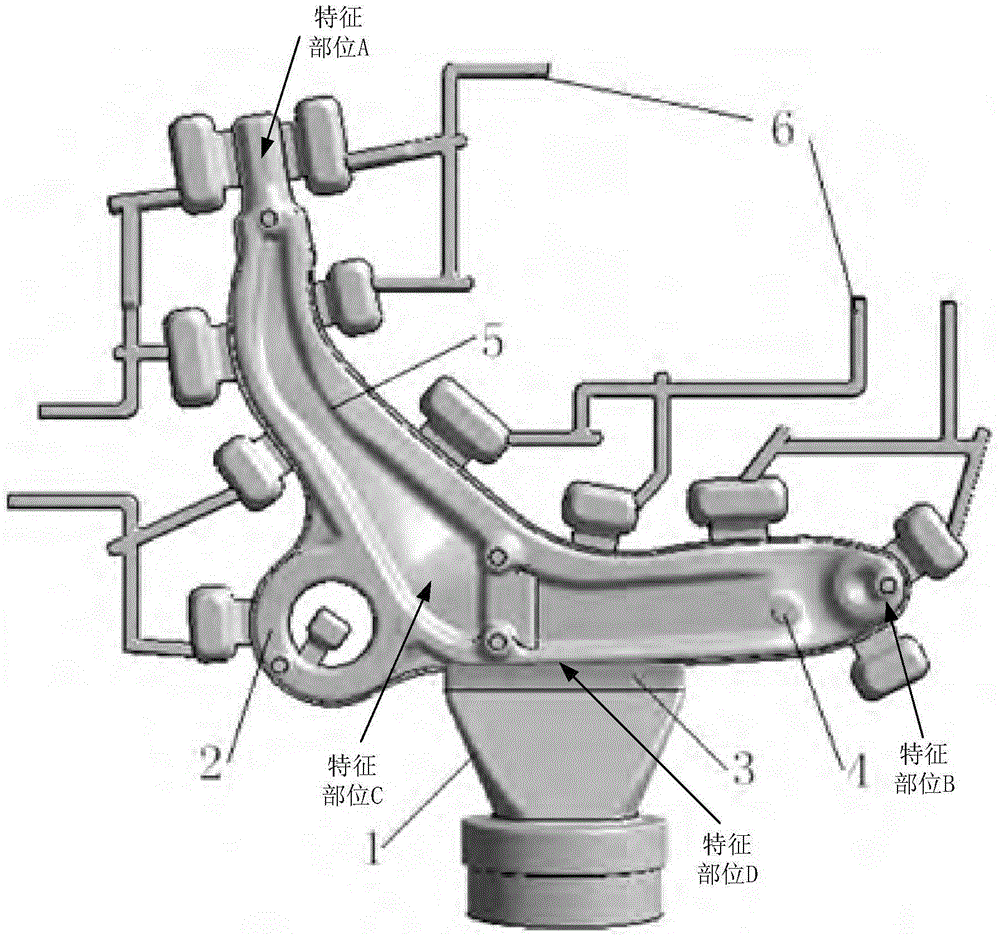

[0091] The lower control arm of the car is made of A356 alloy and weighs 2.4kg. The pouring temperature is 720°C, the mold material is H13 steel, the initial mold temperature is 250°C, and the cooling method is a combination of 6-way water cooling and 3-way air cooling. Control arm configuration and characteristic parts such as Figure 2A shown. Figure 2A The structure refers to "Numerical Simulation and Process Optimization of Automobile Control Arm Squeeze Casting", author Xing Zhiwei, etc.

[0092] see Figure 2B As shown in the pressure-time curve diagram of the rapid pressurization method after holding the pressure, the steps for preparing aluminum alloy automobile chassis castings by using the metal mold low-pressure casting molding and using the rapid pressurization method after holding the pressure are as follows:

[0093] Step 1, liquid ascending stage;

[0094] Under the condition that the liquid lifting pressure is 20kPa and the liquid lifting speed is 2.0kPa / s...

Embodiment 3

[0117] The rear steering knuckle of the car is made of A356 alloy and weighs 2.8kg. The pouring temperature is 720°C, the mold material is H13 steel, the initial mold temperature is 350°C, and the cooling method is a combination of 9-way water cooling and 3-way air cooling. Steering knuckle configuration and characteristic parts such as Figure 1A shown.

[0118] see image 3 As shown in the pressure-time curve diagram of the rapid pressurization method after holding the pressure, the steps for preparing aluminum alloy automobile chassis castings by using the metal mold low-pressure casting molding and using the rapid pressurization method after holding the pressure are as follows:

[0119] Step 1, liquid ascending stage;

[0120] Under the conditions of the liquid lifting pressure of 18kPa and the liquid lifting speed of 2.0kPa / s, the aluminum liquid rises steadily along the liquid rising pipe to the gate of the mold and flows into the mold;

[0121] Step 2, the filling st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com