Anti-floating anchor rod and construction methods thereof

An anti-floating anchor and construction method technology, which is applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve the problems of small friction between the anchor pile and the foundation wall, slurry leakage, and large shrinkage of cement slurry, etc. To achieve the effect of strong anti-floating ability, large friction force and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

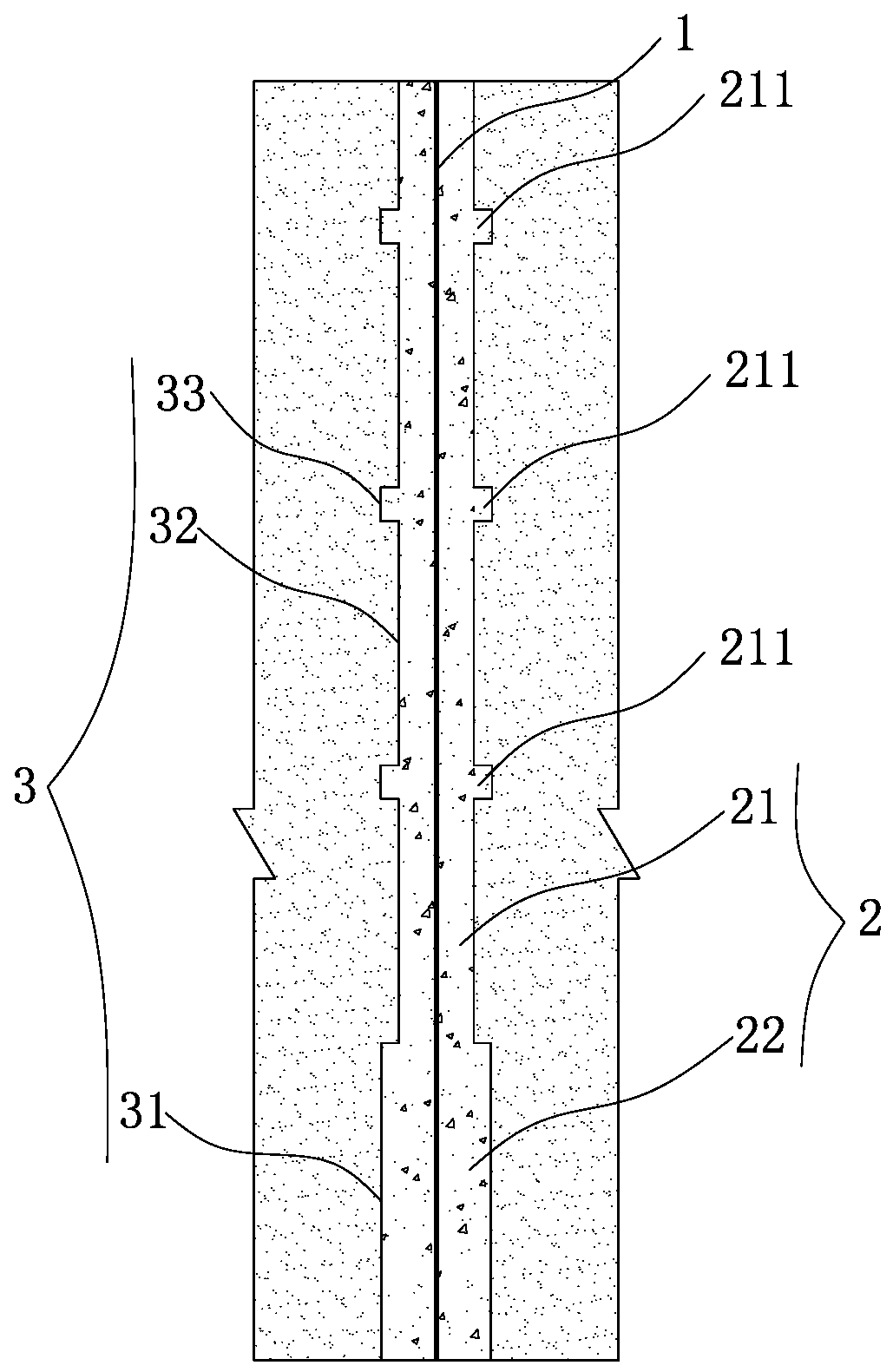

[0032] Such as figure 1 As shown, the present invention discloses an anti-floating anchor, which includes an anchor 1 and an anchor pile 2 that wraps the anchor, and the anchor pile 2 is a concrete pile with a strength of at least C25, so The anchor pile 2 includes a pile main body 21 and an enlarged head 22 connected to the bottom of the pile main body 21; Wherein the height of the expanding head 22 is preferably 2 meters, the diameter of the expanding head 22 is preferably 400 millimeters, the diameter of the pile main body 21 is preferably 250 millimeters, and the anchor rod 1 and the anchor rod pile 2 can be coaxial It is provided that the anchor rod 1 may be threaded steel.

[0033] The anchor pile 2 of a kind of anti-floating anchor rod of the present invention adopts concrete pile, and concrete pile co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com