Alkali-soluble resin polymer and preparation method thereof, photosensitive resin composition and applications of alkali-soluble resin polymer and the photosensitive resin composition

A technology of alkali-soluble resin and photosensitive resin, which is applied in the field of alkali-soluble resin polymer and photosensitive resin composition, and can solve the problems such as the decrease of the flatness of the photoresist, the influence of the display effect and the disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of the above-mentioned color filter may include: coating the above-mentioned photosensitive resin composition on a substrate, and sequentially undergoing steps of pre-baking, exposure, development and post-baking to obtain the color filter.

[0073] The present disclosure is further illustrated by examples below, but the present disclosure is not limited thereby.

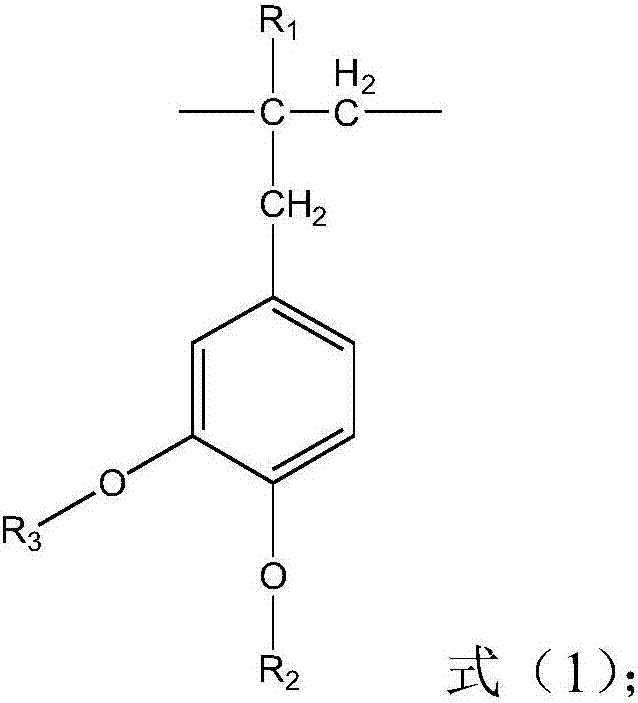

Embodiment 1

[0075] In a 500mL flask, add 18g methacrylic acid (Sinopharm Group, chemically pure), 27g benzyl methacrylate (Bailingwei, analytically pure), 30g N-phenylmaleimide (Bailingwei, analytically pure), 25g of the following formula ( 21) The compound shown in (Anaiji Chemical, analytically pure), 240g propylene glycol methyl ether acetate, 0.3ml molecular weight regulator, nitrogen protection, the system was heated to 80 ° C, under the condition of stirring, using a constant pressure dropping funnel 17g of propylene glycol methyl ether acetate solution and 15g of methacrylic acid dissolved in 1.0g of azobisisobutyronitrile were added dropwise to a three-necked flask within 30 minutes, followed by constant temperature stirring for 3 hours, the temperature was lowered to room temperature, and the solvent was removed. Alkali-soluble resin polymer B1 was obtained. The weight average molecular weight of the polymer measured by GPC is 21360, the molecular weight distribution is 1.98, and...

Embodiment 2

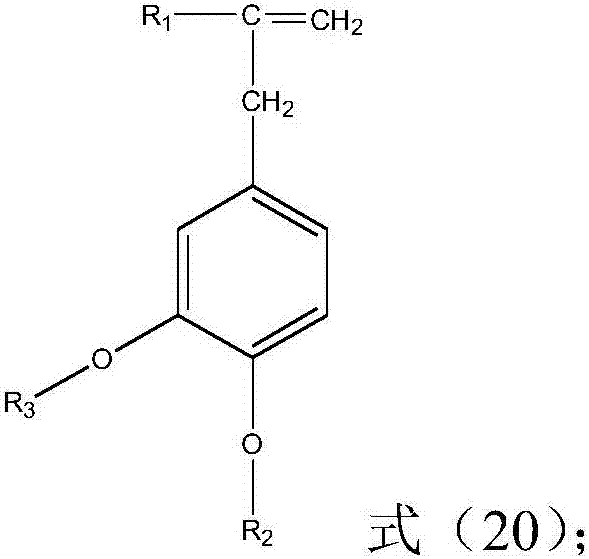

[0078] Adopt the method of embodiment 1, difference is, the compound of formula (21) is replaced by the following formula (22) of equivalent respectively, obtain alkali-soluble resin B2; GPC records alkali-soluble resin polymer B2 polymer weight average The molecular weight is 22050, the molecular weight distribution is 2.10, and the acid value is 114.89mgKOH / g

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com