High-temperature salt-resistant fluid loss agent and production method thereof

A fluid loss reducing agent, high temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor quality stability, low temperature and salt resistance, increased drilling costs, etc., to improve elasticity and The effect of impact resistance, improved cementitious properties, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

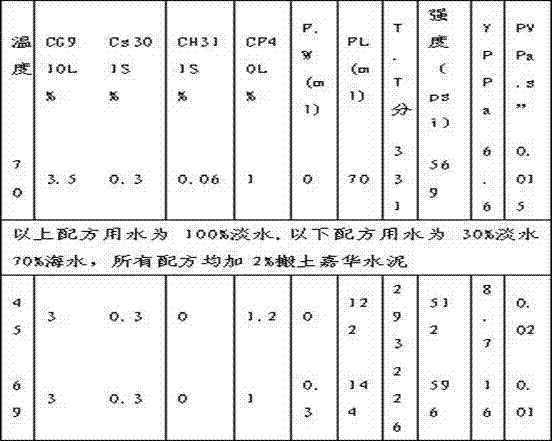

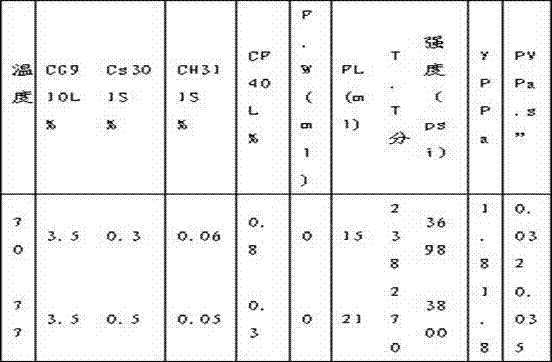

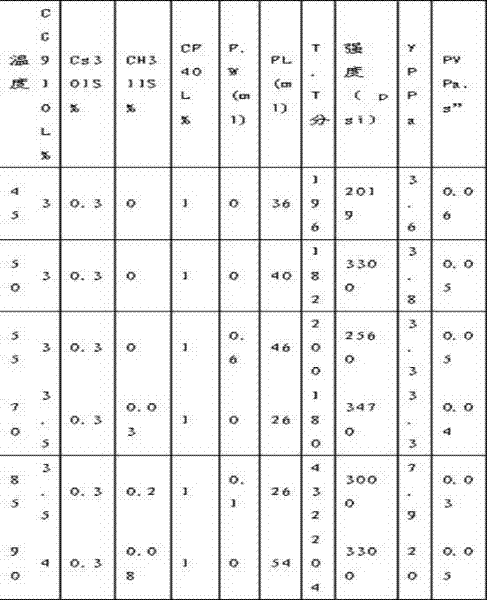

[0025] Now take two groups of high-temperature anti-salt anti-gas channeling agent PCR770L formulas as an example to illustrate the scheme of the present invention,

[0026] raw material name Amount added (kg) 2-Acrylamido 2-methylpropanesulfonic acid 250 Acrylamide 80 Methacrylate 55 Acrylonitrile 220 Ferrous sulfate (activator) 3.5 Ammonium persulfate (initiator) 5.0 Sodium Lauryl Sulfate (Emulsifier) 5.5 Hydroquinone (terminator) 0.55 Deionized water 2400

[0027] Can produce high-temperature anti-salt fluid loss agent CG910: 2980kg.

[0028] raw material name Amount added (kg) 2-Acrylamido 2-methylpropanesulfonic acid 246 Acrylamide 79 Methacrylate 53 Acrylonitrile 216 Ferrous sulfate (activator) 3.4 Ammonium persulfate (initiator) 4.9 Sodium Lauryl Sulfate (Emulsifier) 5.2 Hydroquinone (terminator) 0.55 Deionized water 2380

[0029] Hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com