Photocureable silicon nitride ceramic paste and preparation method thereof

A silicon nitride ceramic and light-curing technology, applied in the field of silicon nitride ceramic preparation, can solve the problems of large deformation of silicon nitride paste, low solid phase content, low single-layer curing depth, etc. The effect of increasing solid phase content and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

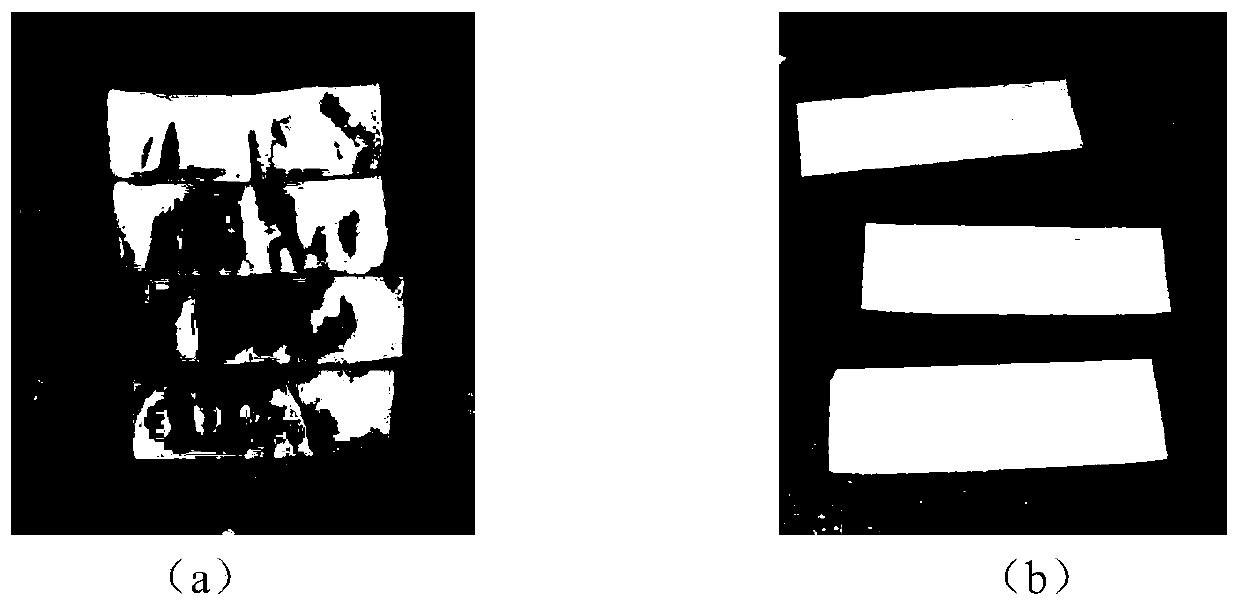

Image

Examples

preparation example Construction

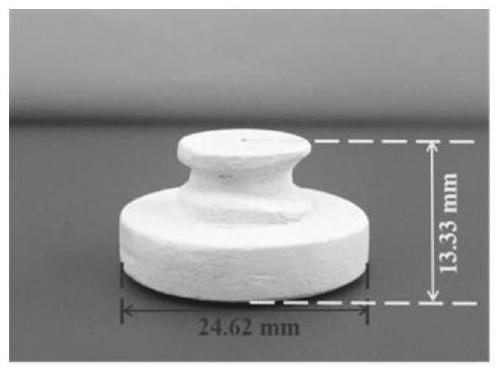

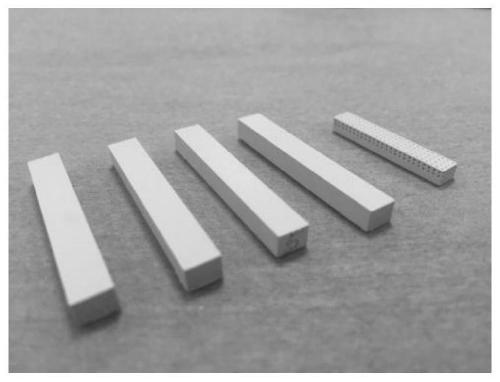

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings. The present invention discloses a light-cured silicon nitride ceramic paste and a preparation method thereof. The preparation method of the ceramic specifically includes the following steps:

[0030] Step 1, mix Si 3 N 4 Powder and sintering aid form ceramic powder, in which Si 3 N 4 The powder is used as the matrix, the mass proportion is 70-90%, the balance is the sintering aid, and the mass percentage of the two is 100%; the sintering aid includes Y 2 o 3 Powder, Al 2 o 3 Powder, SiO 2 Powder, any one of them or a mixture of several, when it is a mixture, the mixing ratio is any ratio; the mixing of the entire ceramic powder adopts particle grading, and 0.5μm Si 3 N 4 Powder, 3.5μm Si 3 N 4 Powder and 0.5μm sintering aid constitute ceramic powder, among which, 3.5μm Si 3 N 4The powder accounts for 70-75% of the mass of the ceramic powder, and the...

Embodiment 1

[0035] Mixed Si 3 N 4 powder and sintering aid to form ceramic powder, Si 3 N 4 The mass proportion of powder is 73%, Y 2 o 3 Powder mass fraction is 5%, Al 2 o 3 Powder mass fraction is 3%, SiO 2 The mass fraction of the powder is 19%; the Si of 3.5μm 3 N 4 Powder mass fraction is 70%, 0.5μm Si 3 N 4 The mass fraction of the powder is 3%, and the balance is 0.5 μm of sintering aid, and stearic acid powder of 3% of the mass of the ceramic powder is added to the mass of the ceramic powder to form a ceramic mixed powder; according to the mass ratio of 0.96:2.25:1.74: 0.87:0.87:1.31:10:7.16 Mix polyurethane, bisphenol A, HDDA, IBOMA, DPHA, TPGDA and TMPTA mixed solution and high refractive index resin to form mixture A, add the photoinitiator TPO of mixture A quality 5%, pass Mix with a homogenizer to obtain a premix; add the ceramic mixed powder and dispersant to the premix, the quality of the premix is 40% of the mass of the ceramic mixed powder, the amount of Tego...

Embodiment 2

[0040] Step 2, paste preparation

[0041] Mixed Si 3 N 4 powder and sintering aid to form ceramic powder, Si 3 N 4 The mass proportion of powder is 75%, Y 2 o 3 Powder mass fraction is 8%, Al 2 o 3 Powder mass fraction is 6%, SiO 2 The mass fraction of the powder is 11%; the Si of 3.5μm 3 N 4 Powder mass fraction is 72%, 0.5μm Si 3 N 4 The mass fraction of the powder is 3%, and the balance is 0.5 μm of sintering aid, and stearic acid powder of 6% of the mass of the ceramic powder is added to the mass of the ceramic powder to form a ceramic mixed powder; according to the mass ratio of 0.93:2.3:1.85: 0.9:0.7:1.2:10:7.3 Mix polyurethane, bisphenol A, HDDA, IBOMA, DPHA, TPGDA and TMPTA mixed solution and high refractive index resin to form mixture A, add 6% photoinitiator TPO of mixture A quality, pass Mix with a homogenizer to obtain a premixed solution; add ceramic mixed powder and dispersant to the premixed solution, the quality of the premixed solution is 35% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com