Method for keeping expansion of steel tube concrete

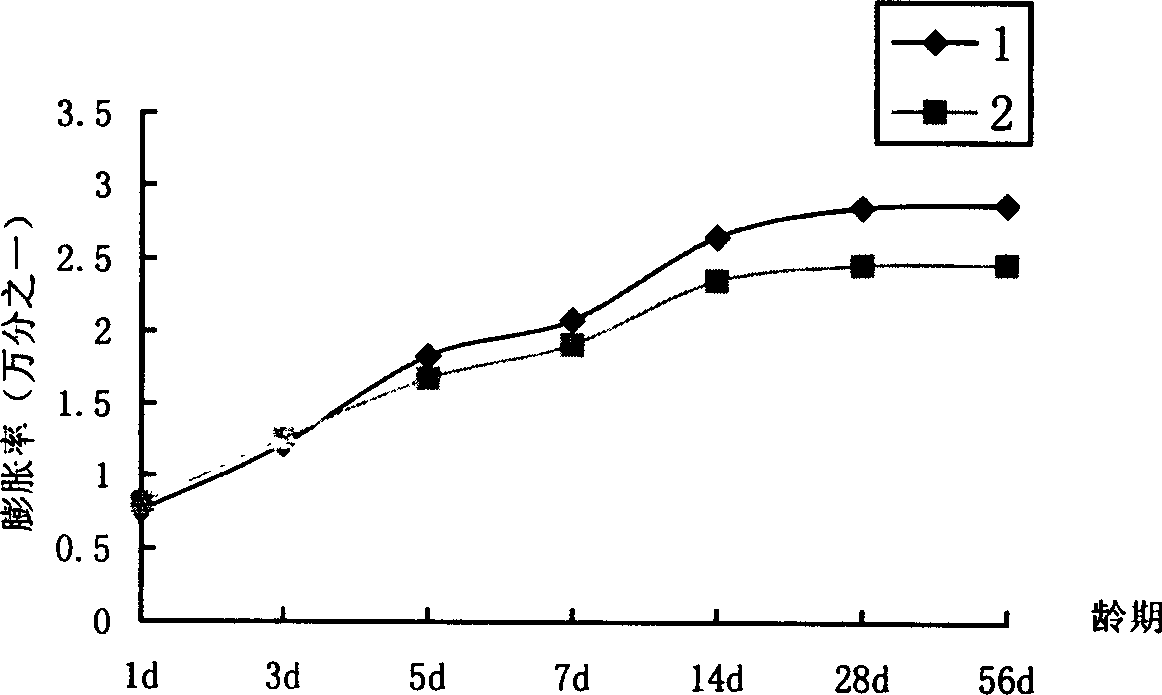

A steel pipe concrete, stable technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of lack of expansion agent, difficulty in functioning, low water consumption, etc., to achieve reduced shrinkage, construction performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0014] Cement: 52.5 # Ordinary Portland Cement;

[0015] Coarse aggregate: 5-20mm continuous graded crushed stone with particle size, crushing value < 10%, needle flake content < 10%;

[0016] Fine aggregate: sand with a fineness modulus of 2.6;

[0017] Lightweight aggregate: high-quality high-strength lightweight aggregate with a water absorption rate of 10% and a cylinder compressive strength greater than 10Mpa;

[0018] Fly ash: Class I fly ash;

[0019] Expansion agent: UEA expansion agent

[0020] Water: tap water;

[0021] Water-reducing and plastic-retaining agent: sulfamate-based high-efficiency water-reducing agent (aminoarylsulfonate-phenol-formaldehyde condensate), with a water-reducing rate of 30%.

[0022]

Preface

No

(Kg / m 3 )

Cement Consumption

(Kg / m 3 )

expansion agent

quantity

(Kg / m 3 )

Fly ash mixed

quantity

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com