Concrete admixture and preparation method thereof

A technology of concrete admixture and water reducing agent, applied in the field of building materials, can solve the problems of poor compatibility of water reducing agent, segregation and stratification, etc., and achieve the effects of low cost, low reaction temperature and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

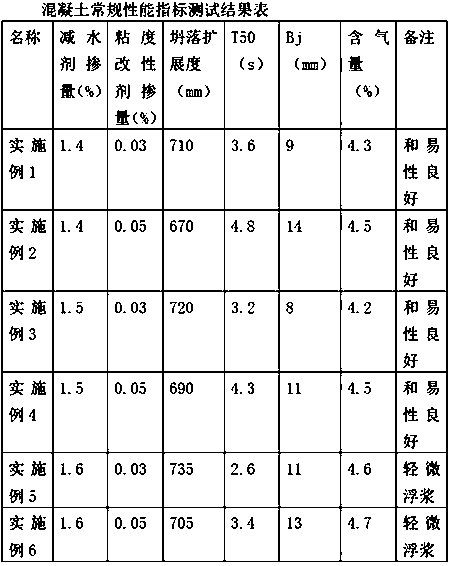

Examples

Embodiment 1

[0018] A concrete admixture, the total mass is 1000g, the concrete admixture is composed of the following raw materials in parts by weight: 280g of water reducer, 6g of viscosity modifier, 100g of expansion agent, and the rest is water;

[0019] In this example, the water reducer is an ether polycarboxylate high-performance water reducer, the viscosity regulator is an industrial grade water-soluble polyvinyl acetate redispersible latex powder, and the expansion agent is a soluble slow-release cement-based gelling material. plastic expansion agent;

[0020] The preparation method of concrete admixture comprises the following steps:

[0021] Add the water reducer, viscosity modifier, expansion agent and water into the disperser in sequence in proportion, raise the temperature to 50-60°C, stir and mix at 2000-2500r / min for 40-50min to obtain an emulsion;

[0022] Step 2: Cool to room temperature after the reaction, and discharge to obtain the concrete admixture.

[0023] Get ab...

Embodiment 2

[0025] A concrete admixture, the total mass is 1000g, the concrete admixture is composed of the following raw materials in parts by weight: 280g of water reducer, 10g of viscosity modifier, 100g of expansion agent, and the rest is water;

[0026] In this example, the water reducer is an ether polycarboxylate high-performance water reducer, the viscosity regulator is an industrial grade water-soluble polyvinyl acetate redispersible latex powder, and the expansion agent is a soluble slow-release cement-based gelling material. plastic expansion agent;

[0027] The preparation method of concrete admixture comprises the following steps:

[0028] Add the water reducer, viscosity modifier, expansion agent and water into the disperser in sequence in proportion, raise the temperature to 50-60°C, stir and mix at 2000-2500r / min for 40-50min to obtain an emulsion;

[0029] Step 2: Cool to room temperature after the reaction, and discharge to obtain the concrete admixture.

[0030] Get a...

Embodiment 3

[0032] A concrete admixture, the total mass is 1000g, the concrete admixture is composed of the following raw materials in parts by weight: 300g of water reducer, 6g of viscosity modifier, 100g of expansion agent, and the rest is water;

[0033] In this example, the water reducer is an ether polycarboxylate high-performance water reducer, the viscosity regulator is an industrial grade water-soluble polyvinyl acetate redispersible latex powder, and the expansion agent is a soluble slow-release cement-based gelling material. plastic expansion agent;

[0034] The preparation method of concrete admixture comprises the following steps:

[0035] Add the water reducer, viscosity modifier, expansion agent and water into the disperser in sequence in proportion, raise the temperature to 50-60°C, stir and mix at 2000-2500r / min for 40-50min to obtain an emulsion;

[0036] Step 2: Cool to room temperature after the reaction, and discharge to obtain the concrete admixture.

[0037] Get ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com