Gear Pump

a gear pump and gear technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve problems such as unstable pump performance, and achieve the effect of stabilizing pump performance and suppressing fluid from leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

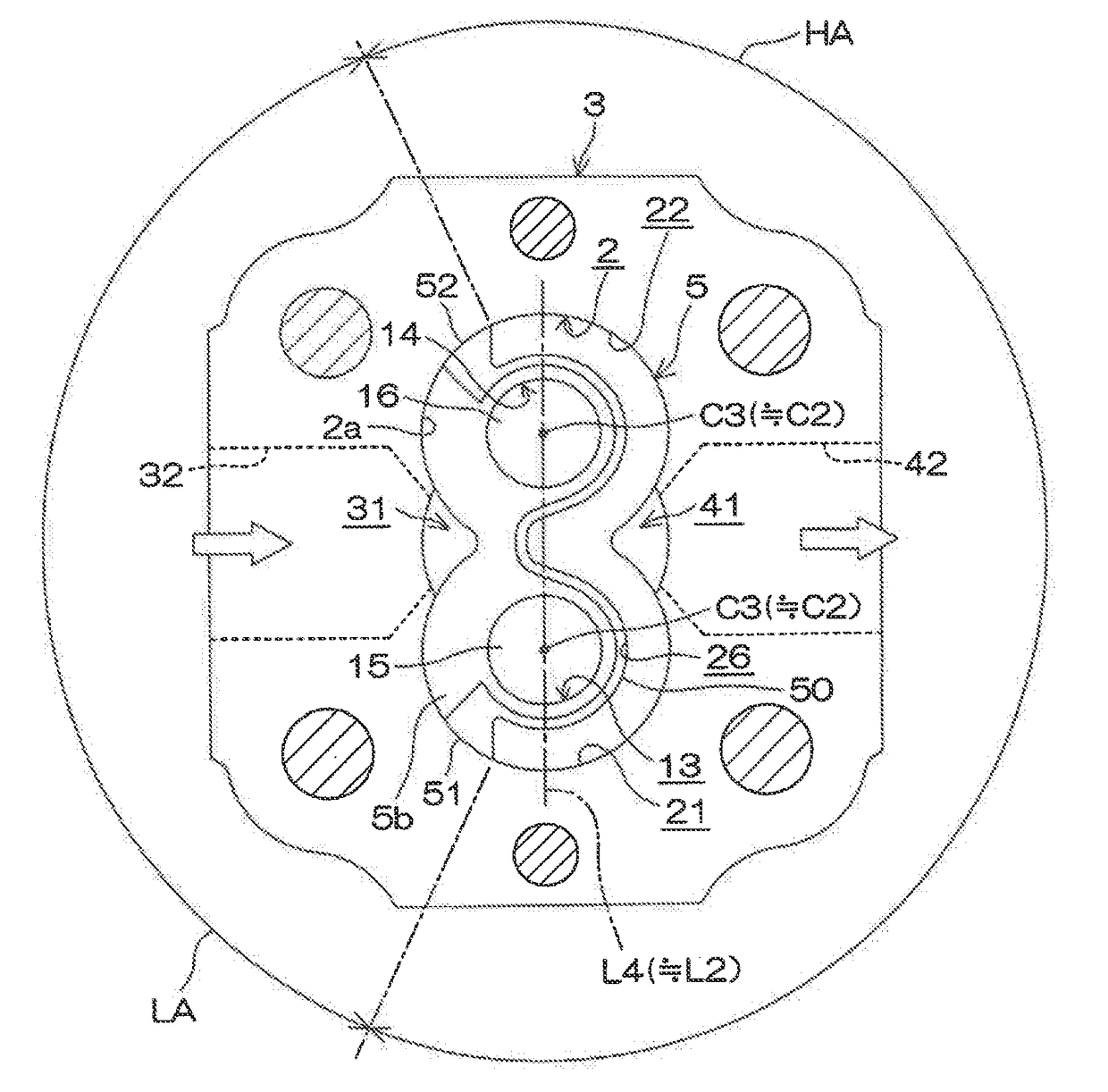

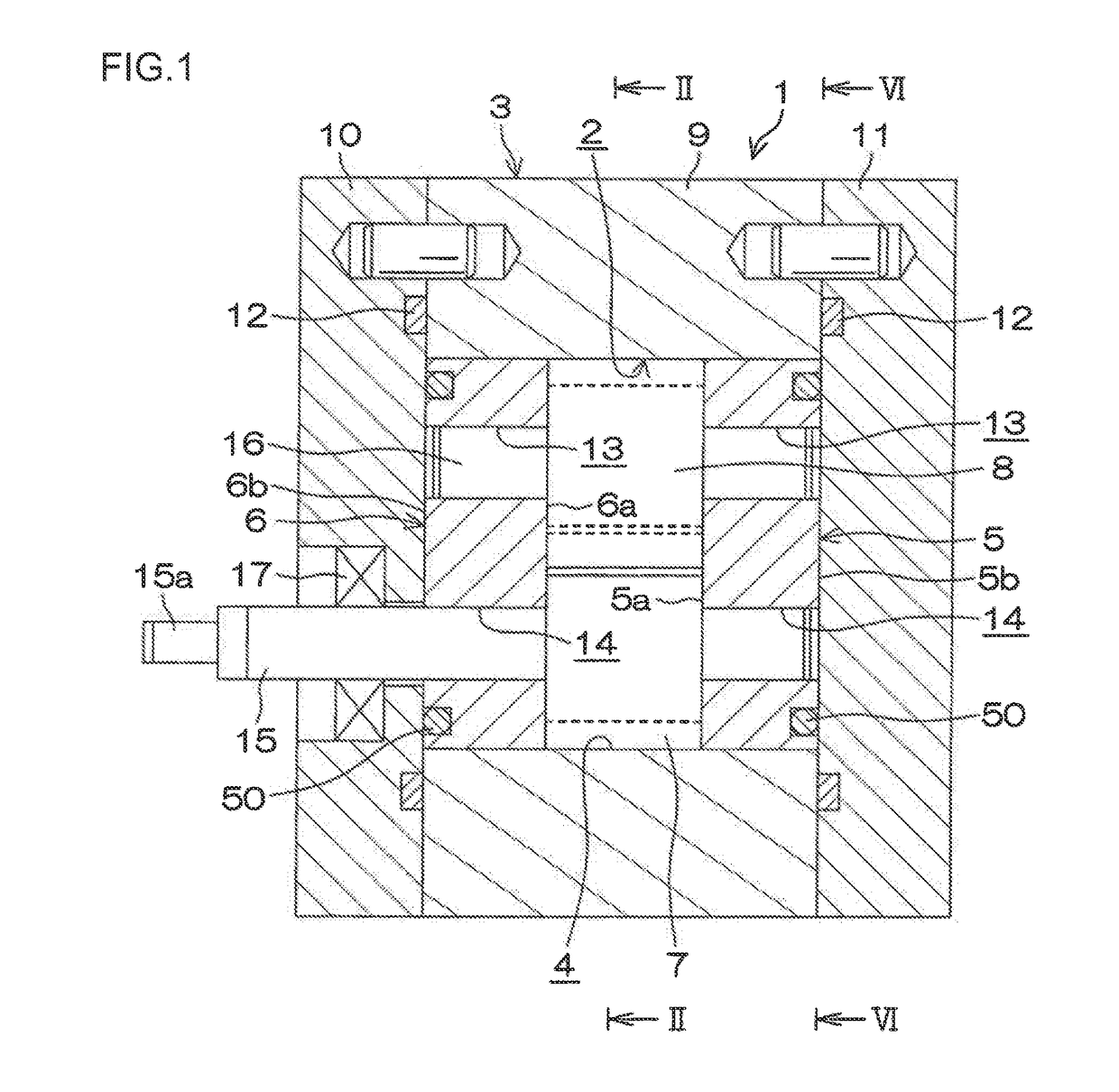

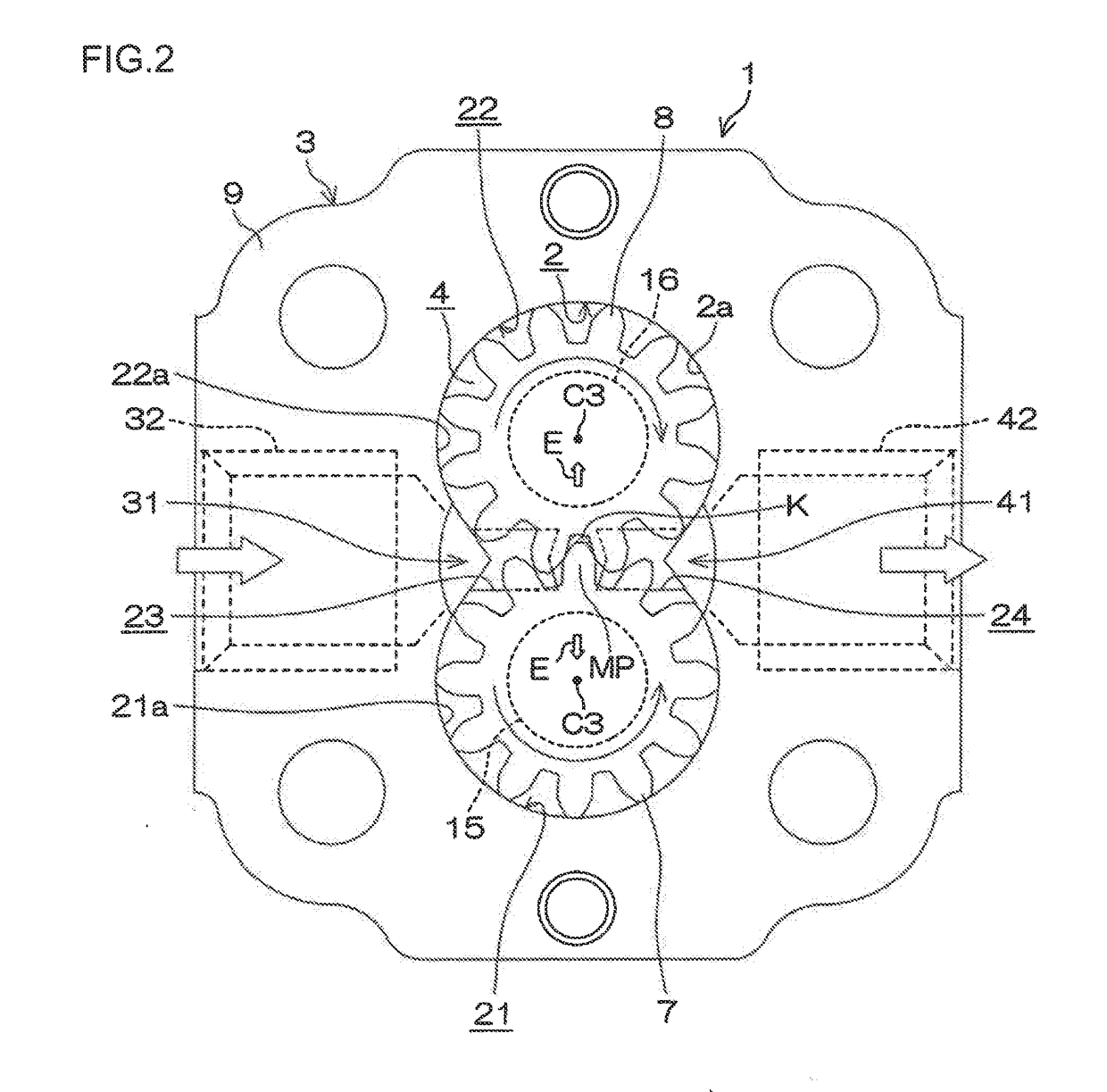

Embodiment Construction

[0023]Example embodiments of the invention will be described with reference to the accompanying drawings. FIG. 1 is a front sectional view of a gear pump according to an embodiment of the invention. FIG. 2 is a sectional view taken along line II-II in FIG. 1, in which hatching representing sections is omitted. As illustrated in FIG. 1 and FIG. 2, a gear pump 1 includes a housing 3, a pair of side plates 5, 6, and a pair of a drive gear 7 and a driven gear 8. The housing 3 has a housing hole 2. The side plates 5, 6 are disposed in the housing hole 2 so as to face each other. The side plates 5, 6 are disposed apart from each other such that a gear chamber 4 is defined therebetween. The drive gear 7 and the driven gear 8 are disposed in the gear chamber 4 so as to be meshed with each other.

[0024]The housing 3 includes a tubular main body 9 and a pair of cover plates 10, 11. The cover plates 10, 11 are screwed to the tubular main body 9 so as to cover both axial end surfaces of the tubu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com