Method for preparing self-supporting diamond film

A diamond film, self-supporting technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of pollution, Si non-reusable environment, prone to cracks, etc., to reduce costs and prevent long-term The effect of distance diffusion and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

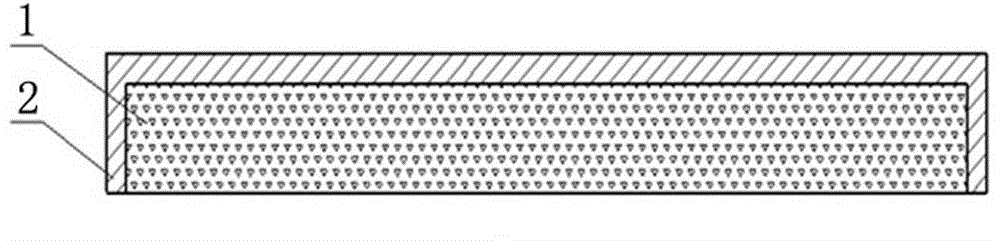

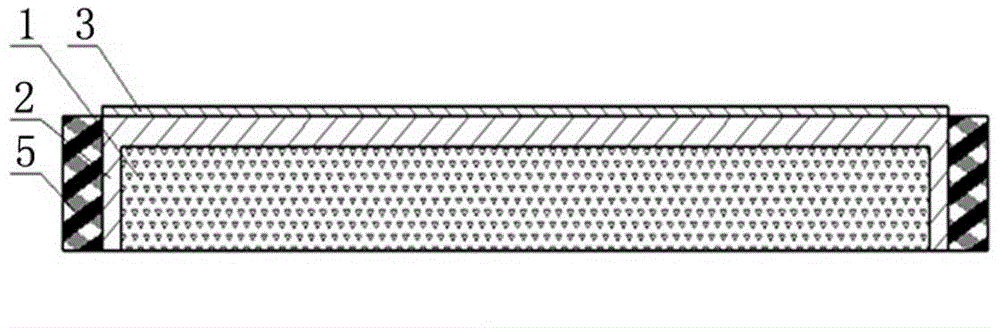

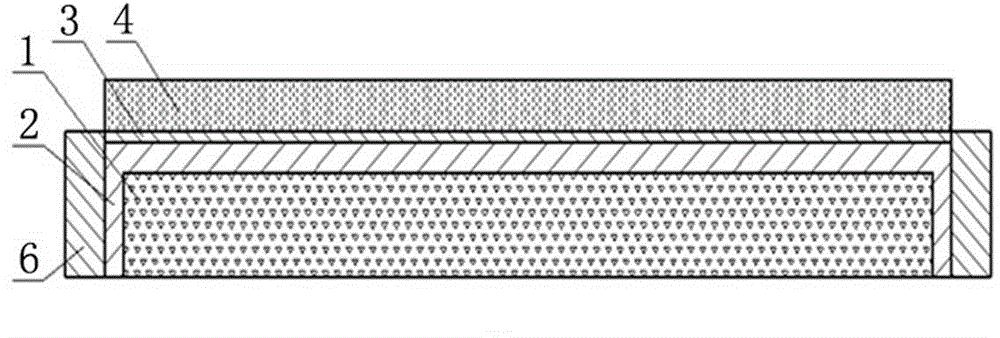

[0029] Such as Figure 1 to Figure 5 Shown, a kind of preparation method of self-supporting diamond film comprises the following steps:

[0030] 1) Titanium coating preparation: take a silicon substrate 1 with a thickness of 3-5 mm, ultrasonically clean it with deionized water and acetone, and dry it with hot air. Prepare a layer of titanium metal coating 2 with a thickness of 10-20 μm on the upper surface and side surface of the silicon substrate 1;

[0031] 2) Preparation of molybdenum coating: using a double-glow plasma metallization method to prepare a layer of molybdenum metal coating 3 with a thickness of 2-4 μm on the titanium metal coating 2 on the upper surface of the silicon substrate 1;

[0032] 3) Preparation of diamond film: use diamond powder with a particle size of 3-10 μm to grind the surface of the molybdenum metal coating 3 on the upper surface of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com