Hardening agent for road and roadbed hardening method

A curing agent and road technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of inability to meet the comprehensive requirements of road construction, low strength of the curing agent, poor curing effect, etc., and achieve the production process. Non-toxic and harmless, good road performance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

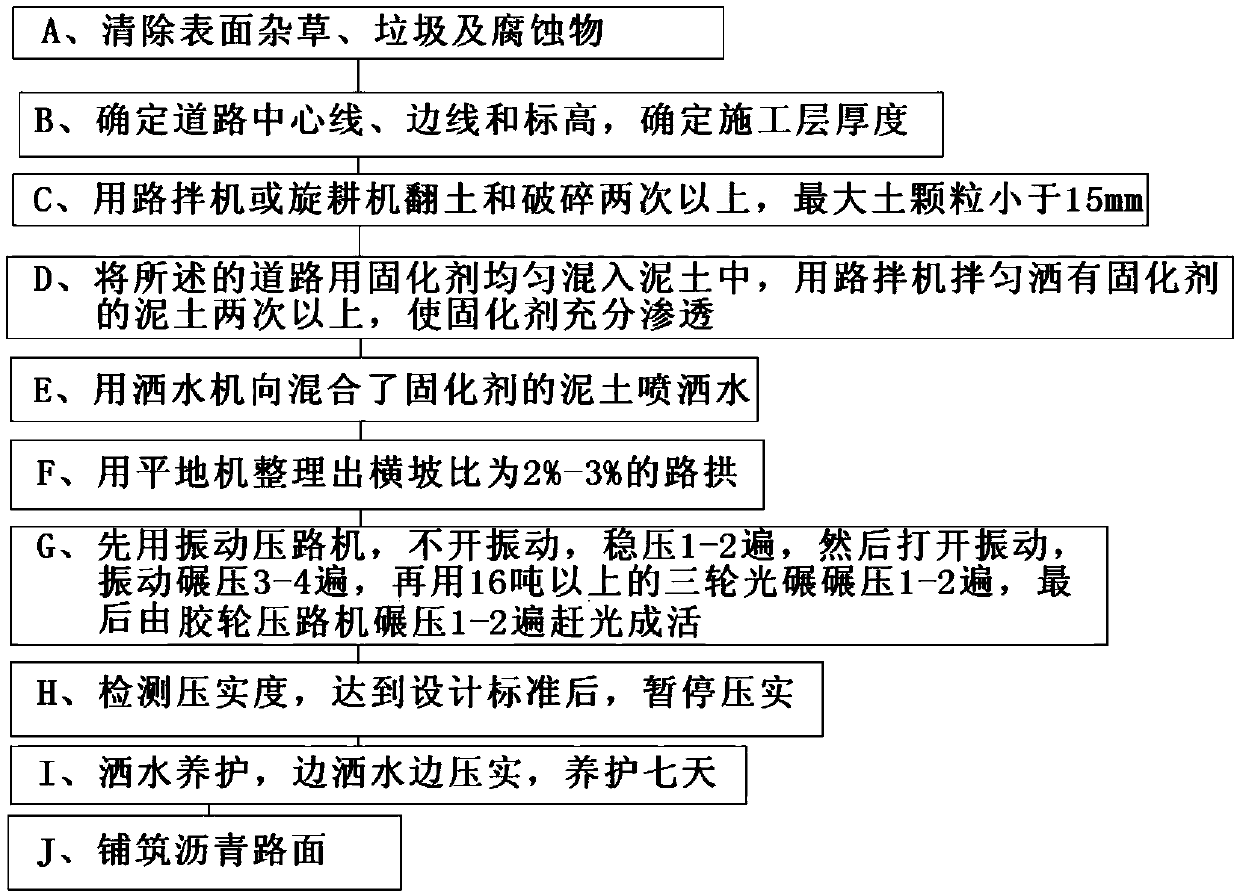

Method used

Image

Examples

Embodiment 1

[0043] The road curing agent of the present invention comprises the following components: by weight percentage, cement 10%-15%, lime 1%-5%, fly ash 2%-3%, gypsum 2%-3%, coal gangue 1%-2%, zeolite 1%-2%, sulfonated oil 3%-15%, phosphate 1%-2%, caustic 1%-2%, potassium permanganate 1%-2%, chloride Sodium 2%-4%, Sodium Carbonate 2%-4%, Calcium Carbonate 2%-3%, Silicon Fume 2%-3%, Asphalt 1%-2%, Water Glass 5%-10%, Polyacrylamide 1 %-2%, polyacrylic acid 1%-2%, magnesium sulfate 1%-2%, calcium carbonate 1%-2%, tar 7%-10%, epoxy resin 0.1%-1%, furfural aniline 0.6%- 1%, calcium acrylate 0.3%-1% and carboxymethyl cellulose 0.5%-2%,

[0044] The curing agent is added with water during use;

[0045] The cement, lime, fly ash and gypsum chemically react under the action of water to form gel-like hydrates, including calcium silicate hydrate, calcium aluminate hydrate and calcium hydroxide, which surround the soil particles and harden Form a skeleton, interact with soil particles to f...

Embodiment 2

[0068] As a further preferred embodiment, the road curing agent includes the following components: cement 120KG, lime 3KG, fly ash 30KG, gypsum 30KG, coal gangue 20KG, zeolite 20KG, sulfonated oil 100KG, phosphate 20KG, caustic soda 20KG, potassium permanganate 20KG, sodium chloride 30KG, sodium carbonate 30KG, calcium carbonate 30KG, silicon powder 30KG, asphalt 20KG, water glass 80KG, polyacrylamide 20KG, polyacrylic acid 20KG, magnesium sulfate 20KG, calcium carbonate 20KG, tar 90KG, epoxy resin 10KG, furfural aniline 10KG, calcium acrylate 10KG and carboxymethyl cellulose 20KG.

[0069] Except for the above content, other parts of the curing agent for roads described in the second embodiment are the same as those of the curing agent for roads described in the first embodiment.

Embodiment 3

[0071] As a further preferred embodiment, the road curing agent includes the following components: by weight percentage, cement 150KG, lime 50KG, fly ash 30KG, gypsum 30KG, coal gangue 20KG, zeolite 20KG, sulfonated oil 150KG, phosphoric acid Salt 20KG, caustic alkali 20KG, potassium permanganate 20KG, sodium chloride 40KG, sodium carbonate 40KG, calcium carbonate 30KG, silicon powder 30KG, asphalt 20KG, water glass 100KG, polyacrylamide 20KG, polyacrylic acid 20KG, magnesium sulfate 20KG, Calcium carbonate 20KG, tar 100KG, epoxy resin 10KG, furfural aniline 10KG, calcium acrylate 10KG and carboxymethyl cellulose 20KG,

[0072] Except for the above content, other parts of the road curing agent described in Embodiment 3 are the same as those described in Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com