Cement concrete pavement Y-shaped joint cutting device and cut joint filling and sealing process

A technology of cement concrete and joint cutting, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of poor driving comfort, short service life, and high labor intensity of operators, so as to achieve good autonomy and mobility and overcome labor intensity. Large, overcome the effect of poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

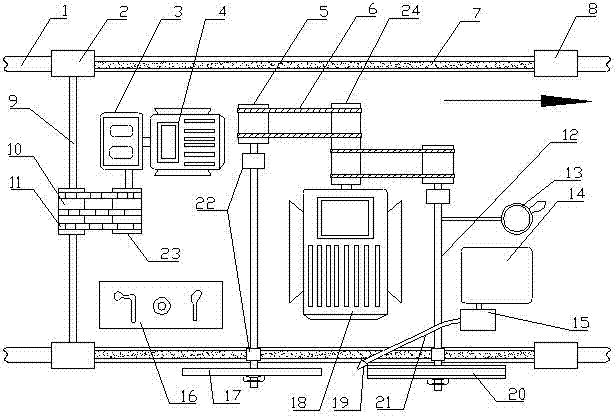

[0046] like figure 1 As shown, a Y-shaped slit device for cement concrete pavement includes a frame 7, and the frame 7 is provided with a traveling mechanism, a cutting mechanism and a cooling mechanism,

[0047] Wherein the traveling mechanism comprises the wheel shaft 9 arranged at the rear portion of the frame 7, the traveling motor 4, the gearbox 3 and the driven wheel 8 arranged at the front end of the frame 7, the two ends of the wheel shaft 9 are provided with driving wheels 2, and the middle end of the wheel shaft 9 A driven sprocket 10 is provided, the main shaft end of the traveling motor 4 is connected with the input shaft of the gearbox 3, and the output shaft of the gearbox 3 is provided with a driving sprocket 23, and the driving sprocket 23 and the driven sprocket 10 pass through the chain 11 connect;

[0048] The cutting mechanism includes a cutting motor 18 arranged in the middle of the frame 7 and two power shafts 12 arranged in parallel. The main shaft end ...

Embodiment 2

[0064] like figure 1 As shown, a Y-shaped slit device for cement concrete pavement includes a frame 7, and the frame 7 is provided with a traveling mechanism, a cutting mechanism and a cooling mechanism,

[0065] Wherein the traveling mechanism comprises the wheel shaft 9 arranged at the rear portion of the frame 7, the traveling motor 4, the gearbox 3 and the driven wheel 8 arranged at the front end of the frame 7, the two ends of the wheel shaft 9 are provided with driving wheels 2, and the middle end of the wheel shaft 9 A driven sprocket 10 is provided, the main shaft end of the traveling motor 4 is connected with the input shaft of the gearbox 3, and the output shaft of the gearbox 3 is provided with a driving sprocket 23, and the driving sprocket 23 and the driven sprocket 10 pass through the chain 11 connect;

[0066] The cutting mechanism includes a cutting motor 18 arranged in the middle of the frame 7 and two power shafts 12 arranged in parallel. The main shaft end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com