Variable-tooth and variable-gap type magnetic fluid reciprocating sealing structure for hydraulic cylinder

A sealing structure and magnetic fluid technology, applied in the direction of engine sealing, fluid pressure actuating device, engine components, etc., can solve the problems of wasting cost, increasing the volume of magnetic fluid sealing structure, etc., and achieve the effect of improving the sealing pressure resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

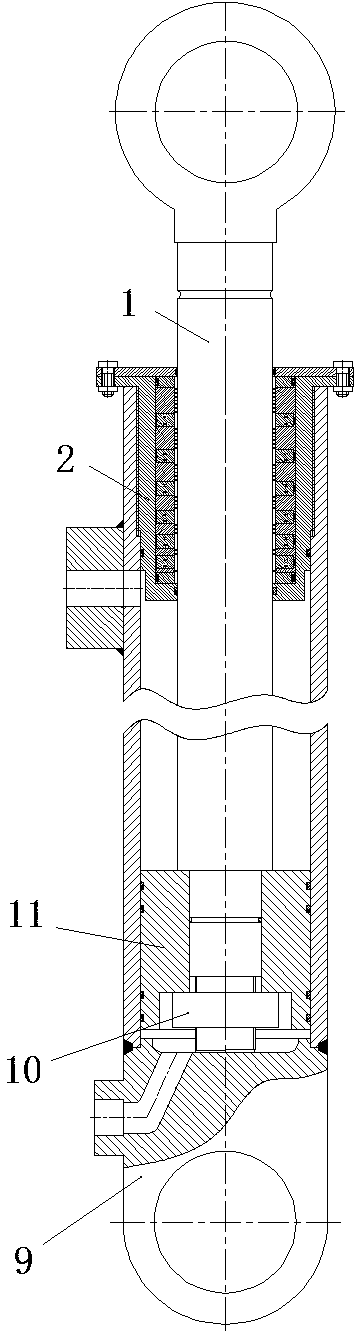

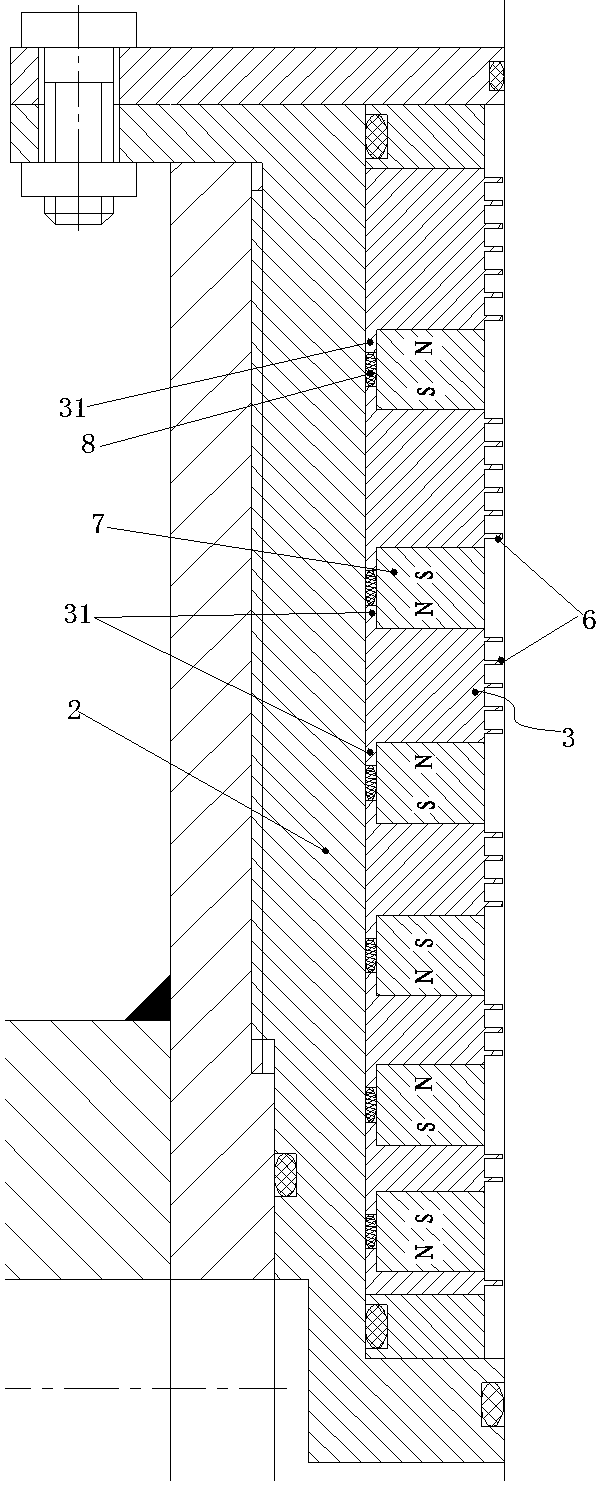

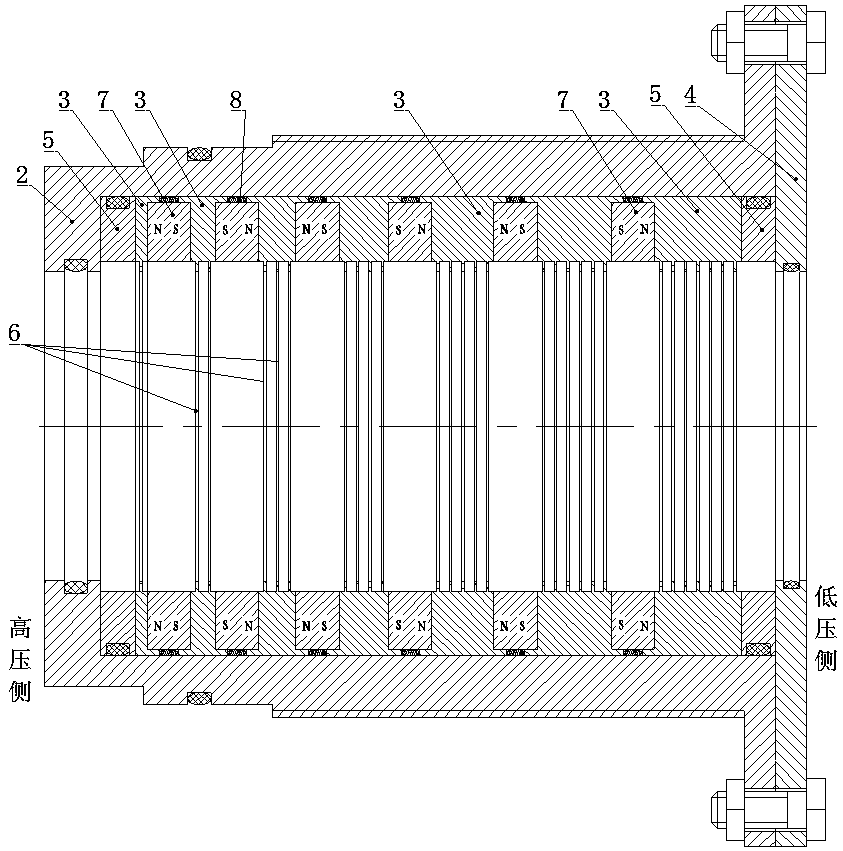

[0032] Such as Figure 1-3 As shown, a variable-tooth variable-gap ferrofluid reciprocating sealing structure for a hydraulic cylinder includes a hollow shell 2, one end of which is closed and the other end is open. A through hole is opened in the center of the closed end face of the housing 2 . It also includes the piston rod 1 penetrating from the through hole to the inner cavity of the housing 2 .

[0033] In the space between the outer surface of the piston rod 1 and the inner wall of the housing 2, a plurality of annular pole pieces 3 are axially spaced apart. Pole teeth 6 are arranged on the inner surface of the pole shoe 3 . An axially magnetized permanent magnet ring 7 is sandwiched between two adjacent pole pieces 3 .

[0034] The cross sections of the pole piece 3 closest to the closed end of the housing 2 and the pole piece 3 closest to the open end of the housing 2 are both L-shaped, and the axial extensions 31 of the two pole pieces 3 face each other. All pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com