A Pressure Adaptive High Speed Lightweight Underwater Cutting Tool

An underwater cutting and self-adaptive technology, applied in the field of auxiliary equipment for diving operations, can solve the problems of oil leakage or water ingress, inconvenience for divers to work, low reliability, etc., to prevent oil and medium water leakage, and high popularization and application The effect of value, function and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

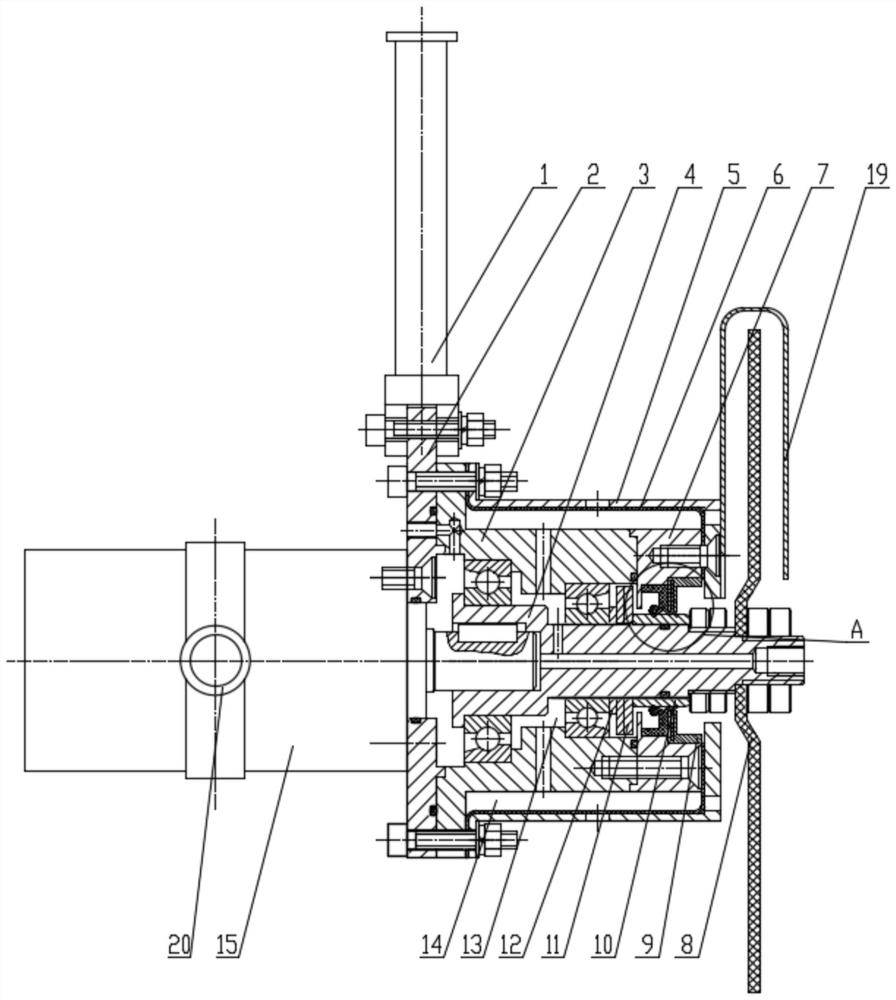

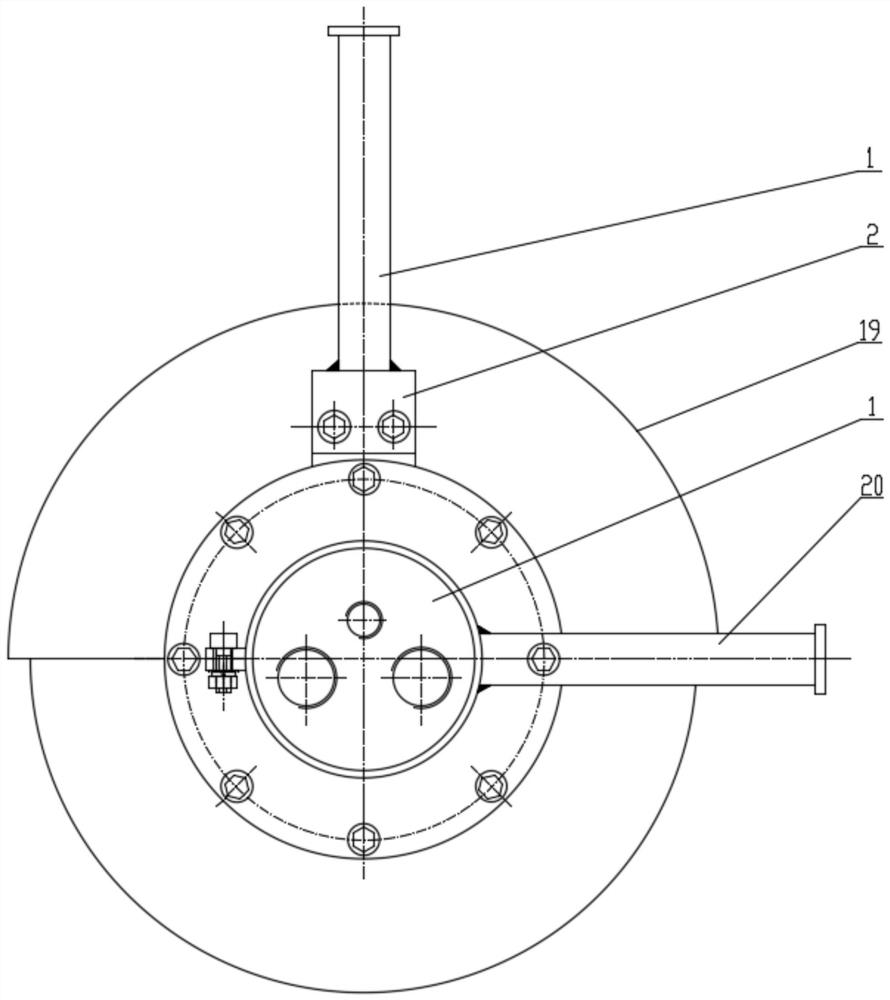

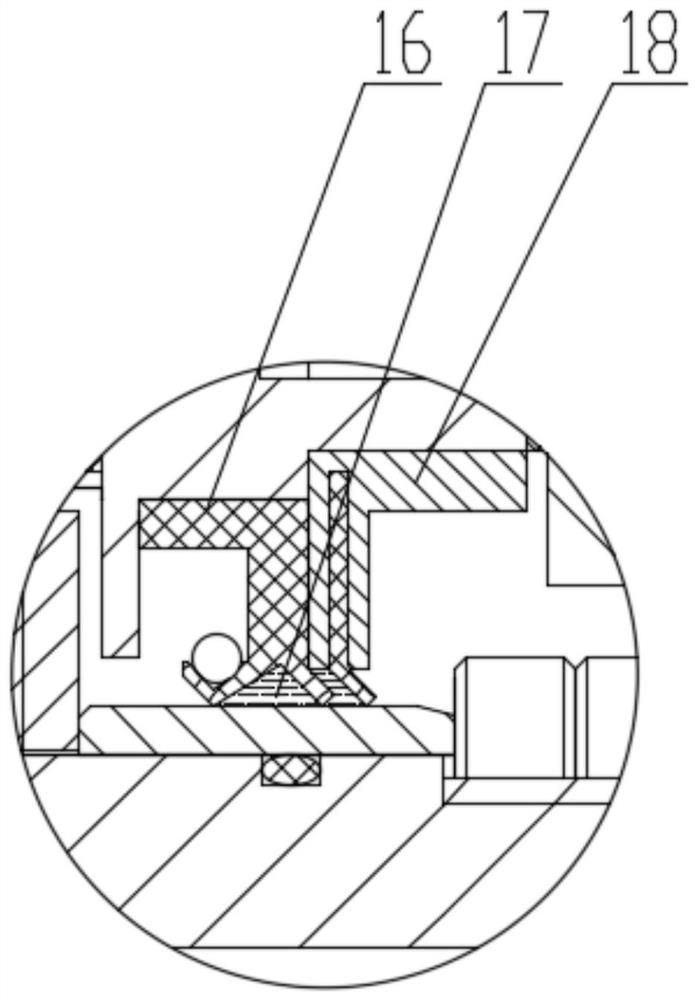

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 and image 3 As shown, the pressure-adaptive high-speed light-duty underwater cutting tool of this embodiment includes a power element 15, and an output shaft 4 is installed through a key at the outlet of the power element 15. The output shaft 4 is stepped, and the first step surface and the The outer circumferential surface of the second stepped surface is equipped with a bearing chamber housing 3 through deep groove ball bearings, and one end of the bearing chamber housing 3 is installed with a flange 2 through a fastener, and a first handle is installed on the upper part of the flange 2 1. The flange 2 is locked with the power element 15 at the same time; a gasket 12 and a pair of disc springs 11 are installed outside the deep groove ball bearing on the second step surface, and a sleeve is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com