Calorific equipment equipped with coaxial heat exchanger

A technology of heat exchangers and equipment, applied in the field of thermal equipment, can solve the problems of lack of elasticity of non-hermetic sealing materials, wear of sealing materials, and inability to be compensated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

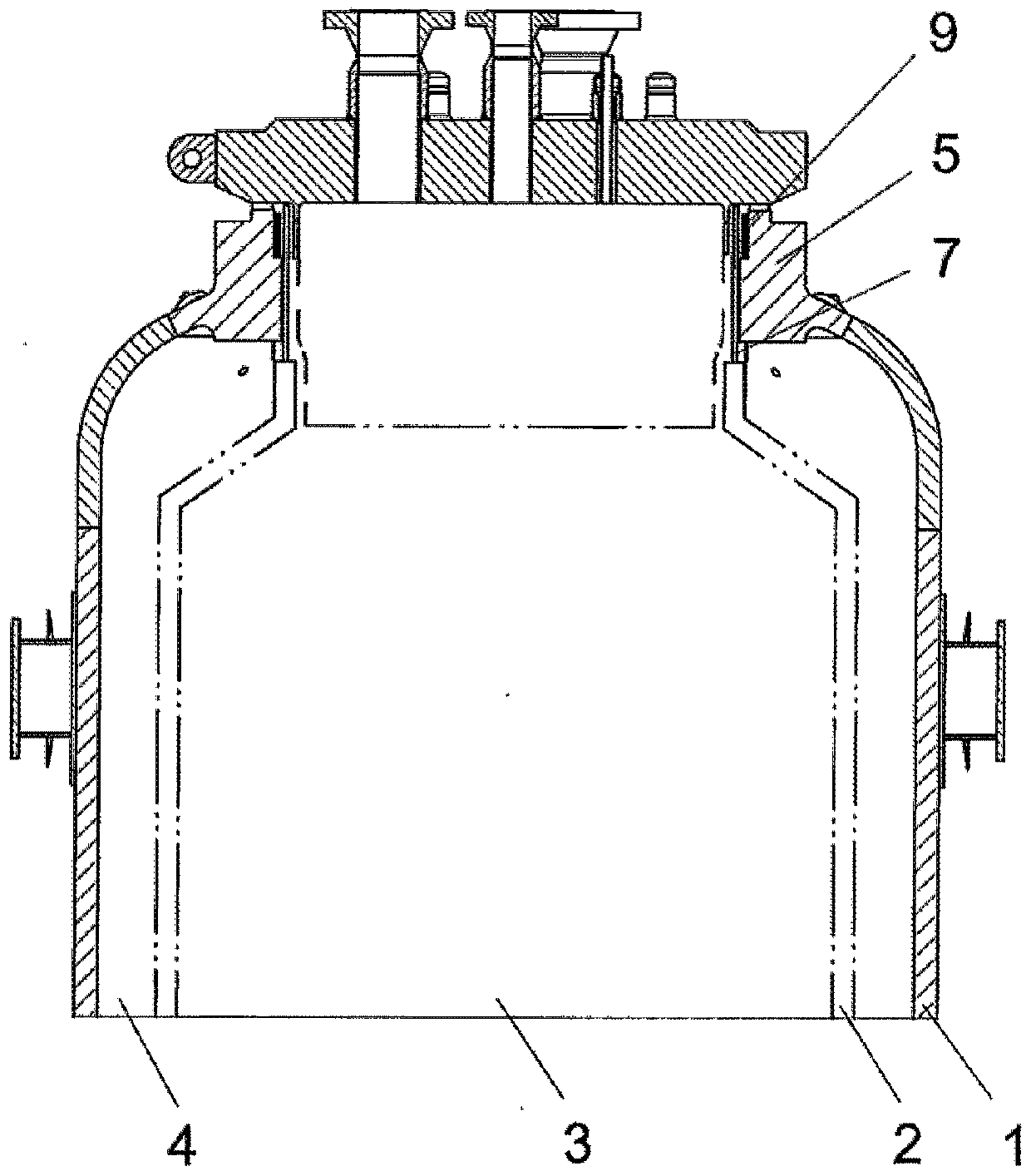

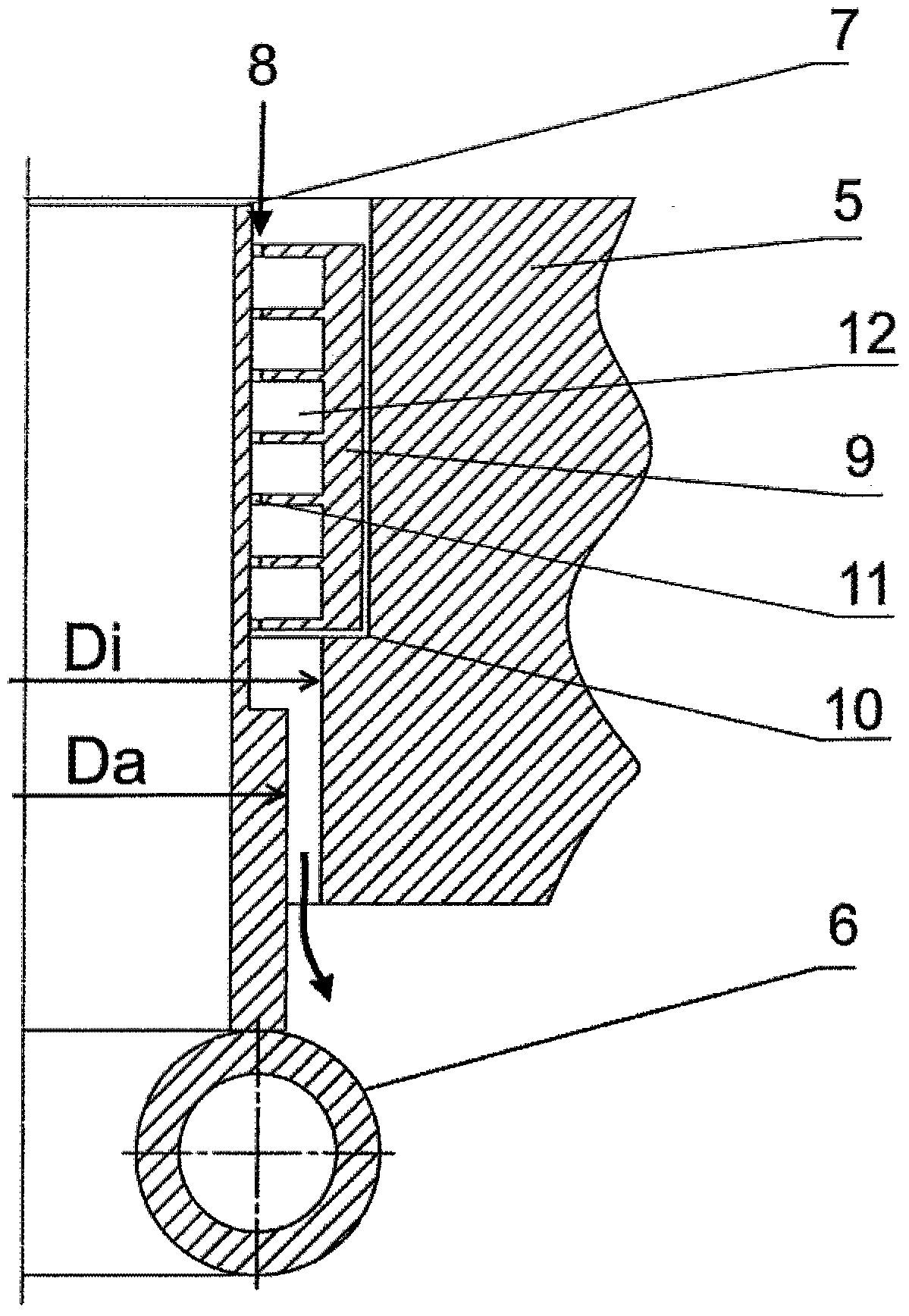

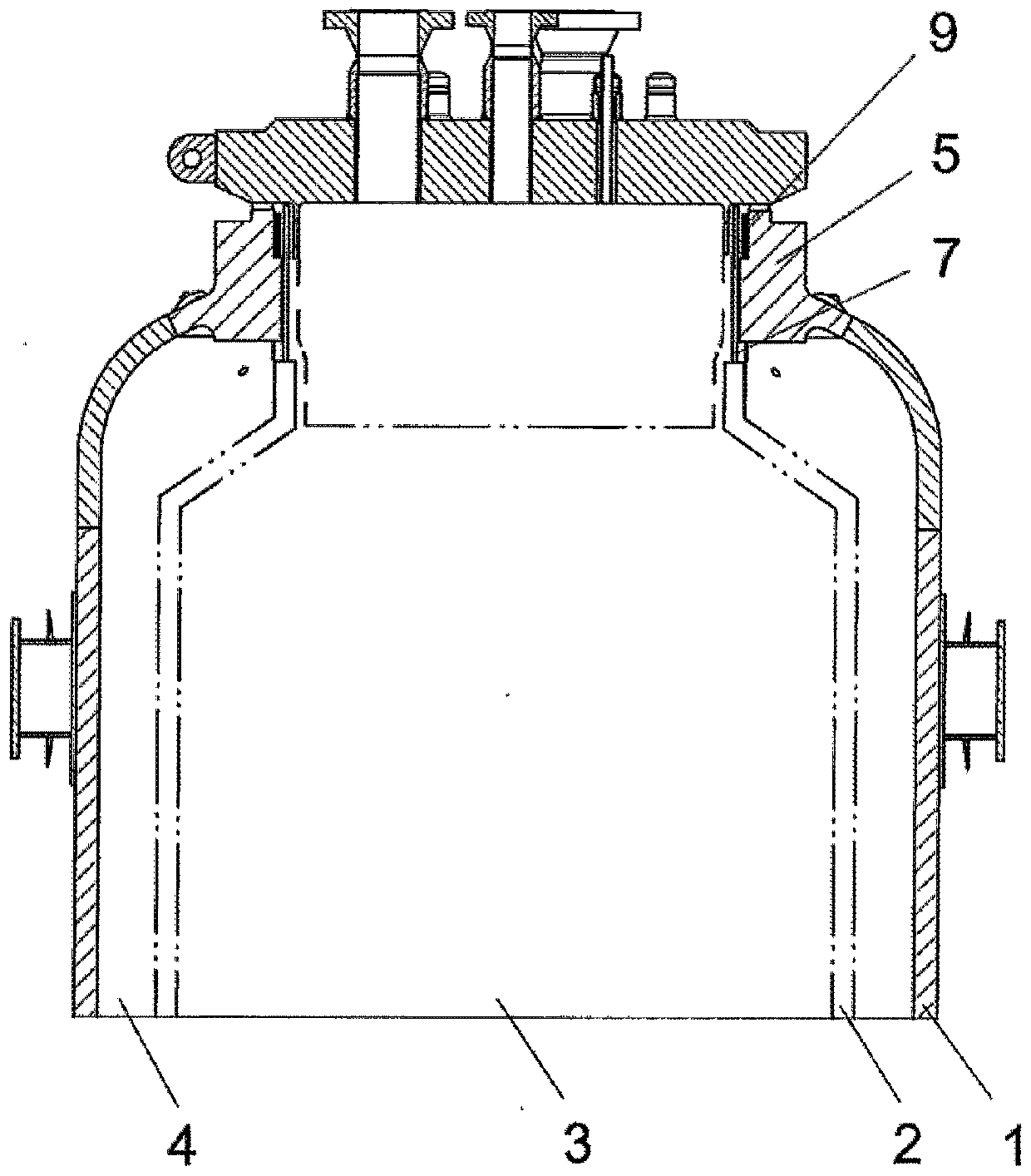

[0025] exist figure 1 In the upper section of a cylindrical gasification reactor with a pressure-tightly closable pressure enclosure 1 shown in , an internal, near-wall heat exchanger 2 (in the gas In the case of chemical reactors, known as cooling screens) are arranged coaxially. The cooling screen is supported on a device bottom (not shown) and forms an annular space 4 opposite the pressure housing 1, wherein the pressure housing 1 has a closable cover flange 5 opposite to the is arranged centrally on the axis of the device and has an inner diameter Di ( figure 2 ).

[0026] The cover flange 5 (which generally also serves to receive the holder of the gasification combustion chamber) is pressure-tightly closed with a flange cover (no reference symbol).

[0027] as from figure 2 As can be seen in the sectional illustration in , the heat exchanger 2 has a plurality of gas-tightly connected coolant channels (here symbolically represented by an upper cooling tube 6 ) and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com