Finger-joint assembled type wood floor

A wood floor and wood strip technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of insufficient strength and inability to maximize the use of leftover wood, so as to improve the connection strength, ensure the service life, and improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

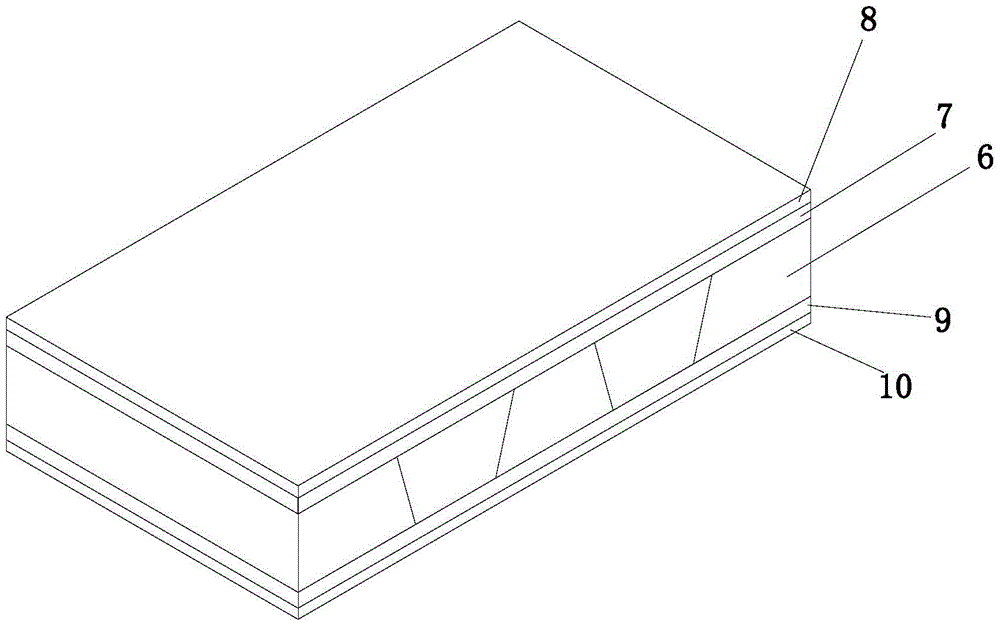

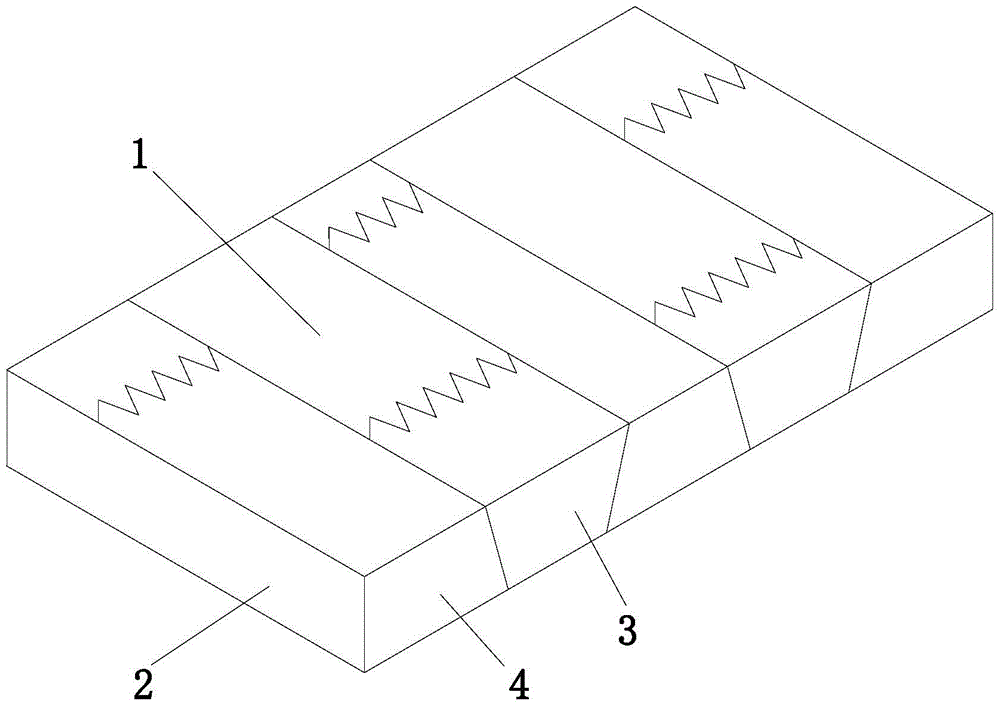

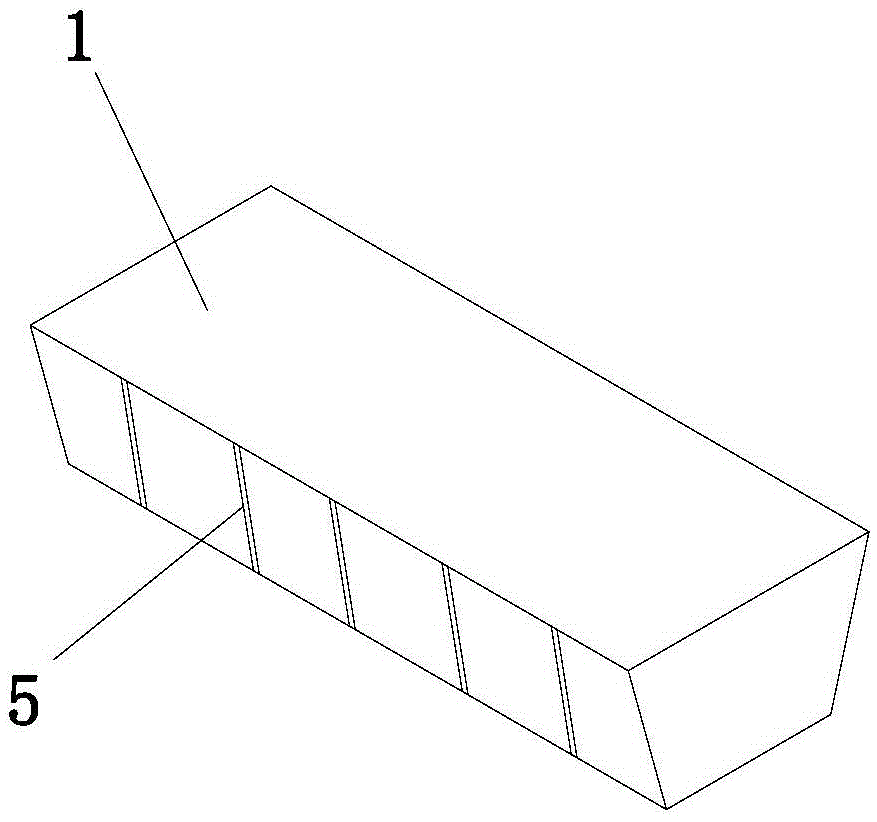

[0014] Example. A finger-jointed assembled wooden floor, constituted as figure 1 , 2 As shown in and 3, it includes a substrate 6, on which a crack-proof layer 7 and an upper veneer 8 are sequentially arranged, and below the substrate 6, a moisture-proof layer 9 and a lower veneer 10 are successively provided, and the substrate 6 includes a plurality of interlaced middle fingers The cross-section of the middle finger-joined wood bar 1 is an isosceles trapezoid 3, and the two sides of the plurality of interlaced middle finger-joined wood bars 1 are respectively provided with side finger-joined wood bars 2. The cross-section is a right-angled trapezoid 4; the inclination angles of the inclined surfaces on both sides of the middle finger-jointed wooden strip 1 and the inclined surface on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com