Sealing and guiding structure of a breaking hammer

A technology of guiding structure and breaking hammer, applied in the directions of piston rings, mechanical equipment, engine components, etc., can solve the problems of high requirements on concentricity of piston and cylinder seals, scrapped pistons and cylinders, and short life of seals. Maintenance and repair costs, reduced machining costs, and improved sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, invention is described in further detail.

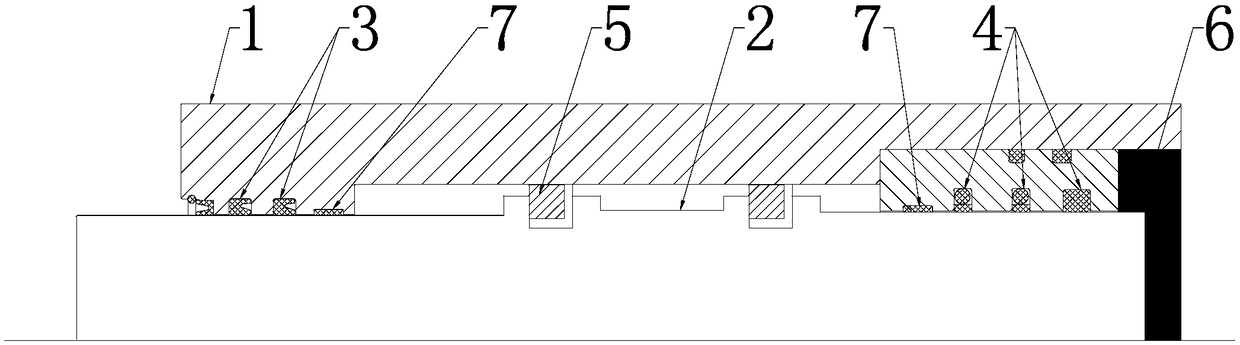

[0010] Such as figure 1 As shown, a sealing and guiding structure of a breaking hammer includes a cylinder body 1, a piston 2, a lower cavity seal 3 between the cylinder body 1 and the piston 2, a nitrogen gas seal 4, and nitrogen gas 6 in the cylinder body 1. A guide ring 7 is arranged in the cavity formed by the cylinder body 1 and the piston 2 between the lower cavity seal 3 and the nitrogen gas seal 4 , and a floating seal 5 is arranged between the cylinder body 1 and the piston 2 . A guide ring 7 is added at the upper and lower ends of the cavity where the seals are installed to guide the movement of the piston 2 . In addition, the gap seal of the piston 2 is changed to a floating seal, and the floating seal can have one or several upper and lower seals. The floating seal 5 is installed on the piston 2. The outer ring surface of the floating seal 5 is attached to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com