Combined honeycomb seal made of polyether-ether-ketone resin materials and method for manufacturing combined honeycomb seal

A technology of polyetheretherketone resin and honeycomb sealing, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of friction coefficient grinding shaft, small design gap, metal honeycomb seal corrosion, etc., and achieve stable product quality, Improve processing efficiency and save material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

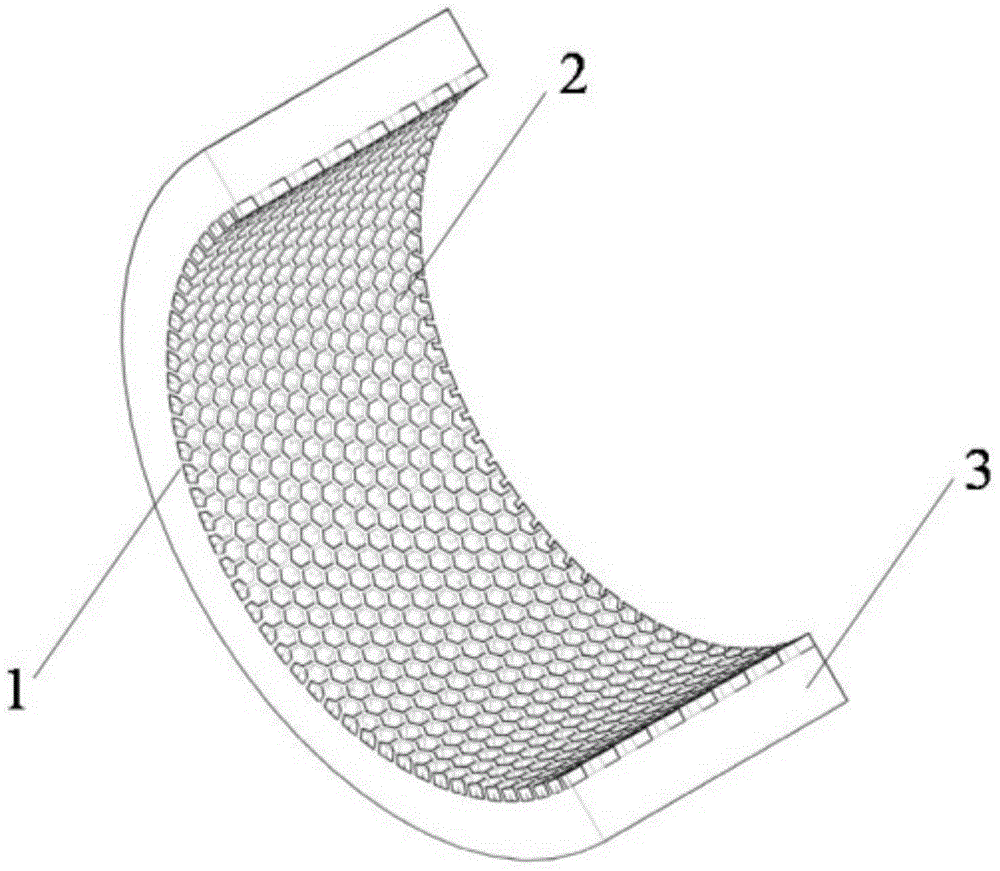

[0023] Such as figure 1 As shown, the combined honeycomb seal 1 prepared in Example 1 is obtained by assembling a polyether ether ketone resin non-metallic honeycomb sealing tape 2 and a metal base 3, and its size is 200 mm in outer diameter, 100 mm in inner diameter, and 30 mm in height.

[0024] The honeycomb sealing tape 2 is made of polyether ether ketone resin non-metallic materials by injection molding, and the specific preparation process is:

[0025] a. According to the size and technical requirements of the sealing body, the size of the honeycomb sealing tape 2 is designed to be 104mm in outer diameter, 100mm in inner diameter, and 30mm in height. In addition, the honeycomb sealing hole on the honeycomb sealing tape 2 is a regular hexagonal through hole with a regular shape, with a side distance of 4mm, a wall thickness of 1mm, and a depth of 2mm.

[0026] b. Design the corresponding injection mold according to the size of the honeycomb sealing tape 2;

[0027] c. Dry the pe...

Embodiment 2

[0032] Such as figure 1 As shown, the combined honeycomb seal 1 prepared in Example 2 is obtained by assembling a polyether ether ketone resin non-metallic honeycomb sealing tape 2 and a metal base 3, and has an outer diameter of 400 mm, an inner diameter of 200 mm, and a height of 170 mm.

[0033] The honeycomb sealing tape 2 is made of polyether ether ketone resin non-metallic materials by injection molding, and the specific preparation process is:

[0034] a. According to the size and technical requirements of the sealing body, the size of the honeycomb sealing tape 2 is designed to be 212mm in outer diameter, 200mm in inner diameter and 170mm in height. In addition, the honeycomb sealing hole on the honeycomb sealing tape 2 is a regular hexagonal blind hole with a regular shape, with a side distance of 10mm, a wall thickness of 2mm, and a depth of 5mm.

[0035] b. Design the corresponding injection mold according to the size of the honeycomb sealing tape 2;

[0036] c. Dry the pe...

Embodiment 3

[0041] The difference from Embodiment 1 lies in that the honeycomb sealing holes on the honeycomb sealing tape 2 are regular hexagonal through holes, with regular shape, 6mm edge distance, 0.5mm wall thickness and 1.6mm depth. The mold heating temperature was set to 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com