Filtering driving device and intelligent robot integrated system

A technology of intelligent robots and driving devices, applied in manipulators, manufacturing tools, etc., can solve the problems of shortened service life, poor workmanship, and reduced mechanical efficiency of equipment, and achieve simple manufacturing and processing technology, low manufacturing cost, and easy installation and debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

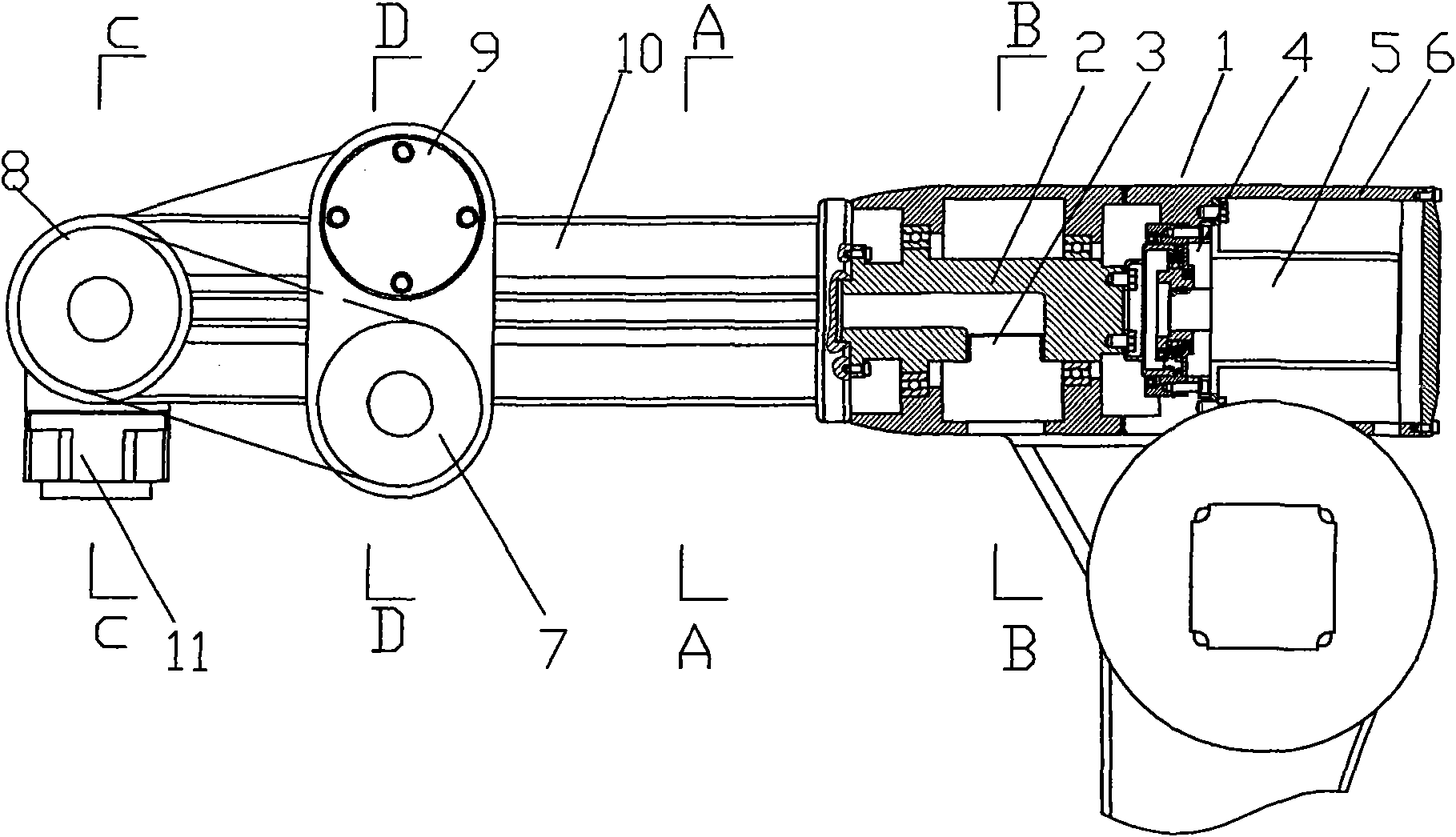

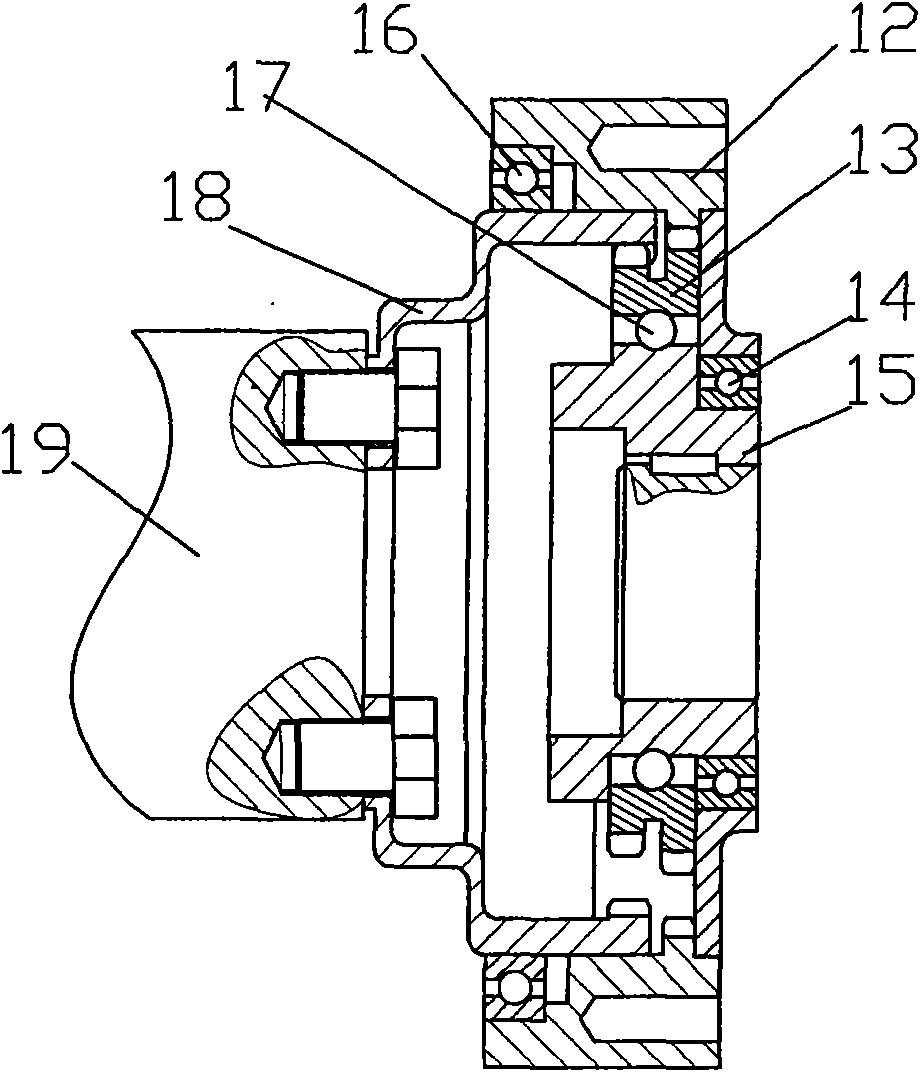

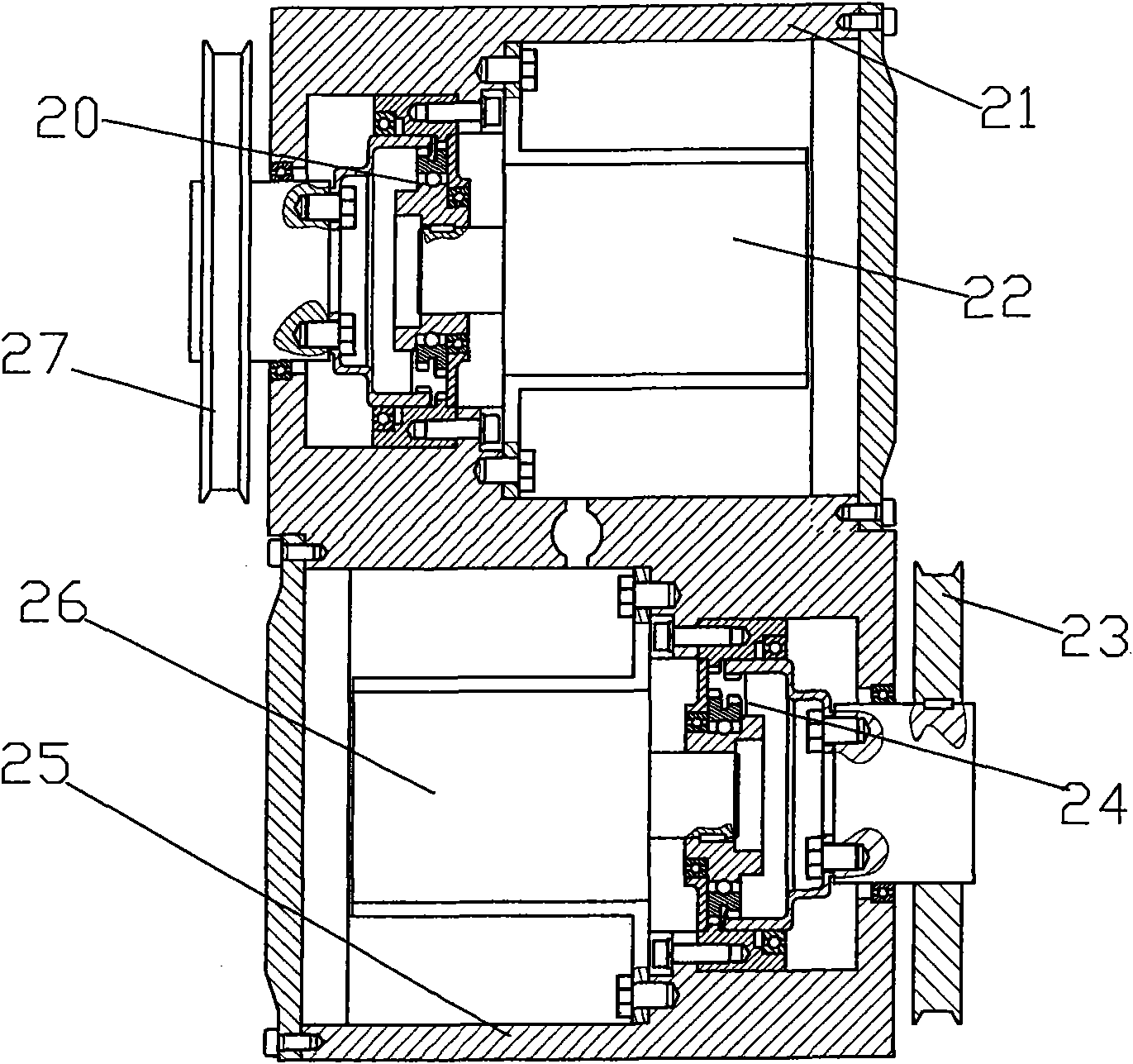

[0027] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the reducer with small tooth difference in the present invention, image 3 for figure 1 Sectional view along A-A direction, Figure 4 for figure 1 Sectional view along B-B direction, Figure 5 for figure 1 Sectional view along C-C direction, Figure 6 for figure 1 Sectional view along D-D direction, Figure 7 It is a schematic diagram of the cross-section of the mechanical wrist joint shell, as shown in the figure: the integrated system of the filter drive device and the intelligent robot in this embodiment includes a mechanical arm 10 and a mechanical wrist 11, and one end of the mechanical arm 10 is provided with a device to drive it to rotate around its own axis Arm driving device 1, the other end of which is hinged with a single degree of freedom of mechanical wrist 11 through a mechanical wrist joint 8. The mechanical wrist joint 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com