Compound milling shoes with various cutting elements

A cutting element and compound grinding technology, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as jamming, excessive debris particles, etc., to enhance the life of grinding shoes, improve adaptability, and improve drilling and grinding effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

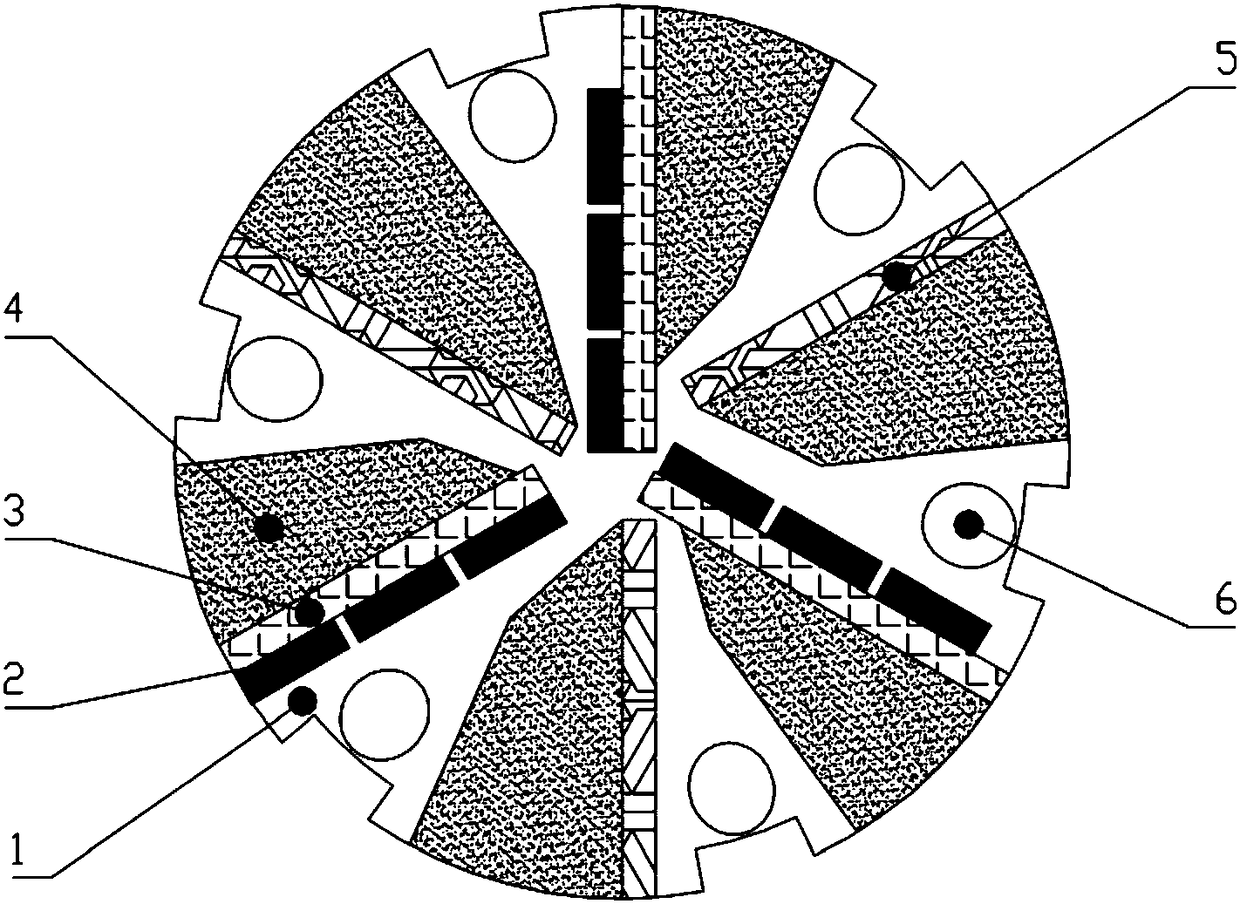

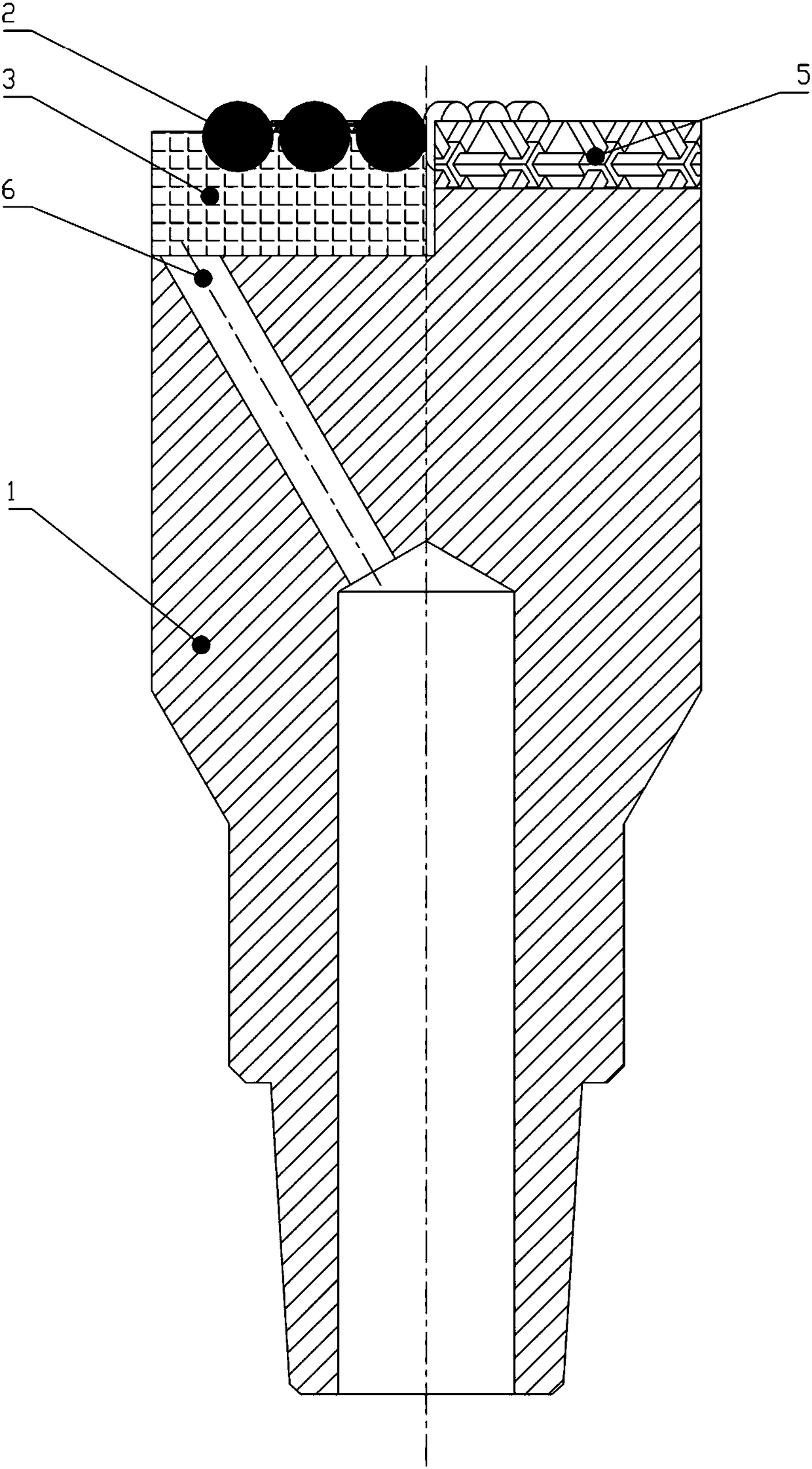

[0013] refer to figure 1 , the structure of the present invention is to include the main body of the grinding shoe 1, the main body of the grinding shoe 1 is distributed with a polycrystalline diamond composite blade 3 and a second-stage cutting blade 5 at intervals, and in front of the polycrystalline diamond composite blade 3 along the radial direction A plurality of polycrystalline diamond composite sheets 2 are arranged, and irregular hard alloy cutting particles 4 are surfacing at the back of each polycrystalline diamond composite sheet blade 3 and the second-stage cutting blade 5; the fluid passes through every two The water hole 6 that arranges between two blades cools down the grinding shoes of work and the debris of drilling and grinding is taken out of the bottom of the well.

[0014] The polycrystalline diamond composite blade 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com