Strip steel flattening machine

A technology of levelling machine and strip steel, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of poor leveling effect, easy strip steel stuck, uneven strip tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

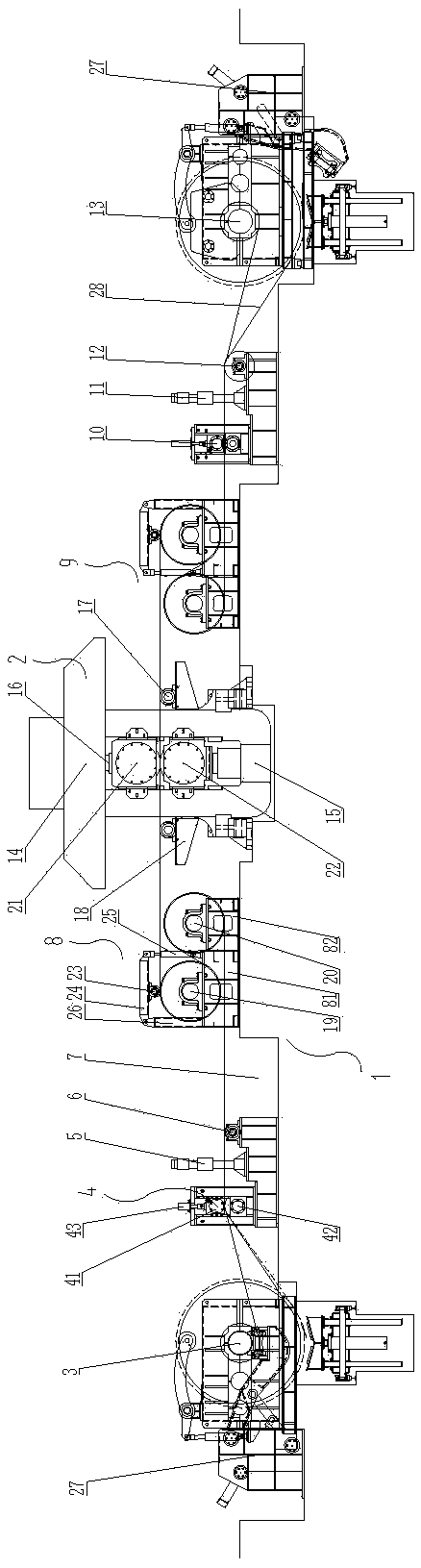

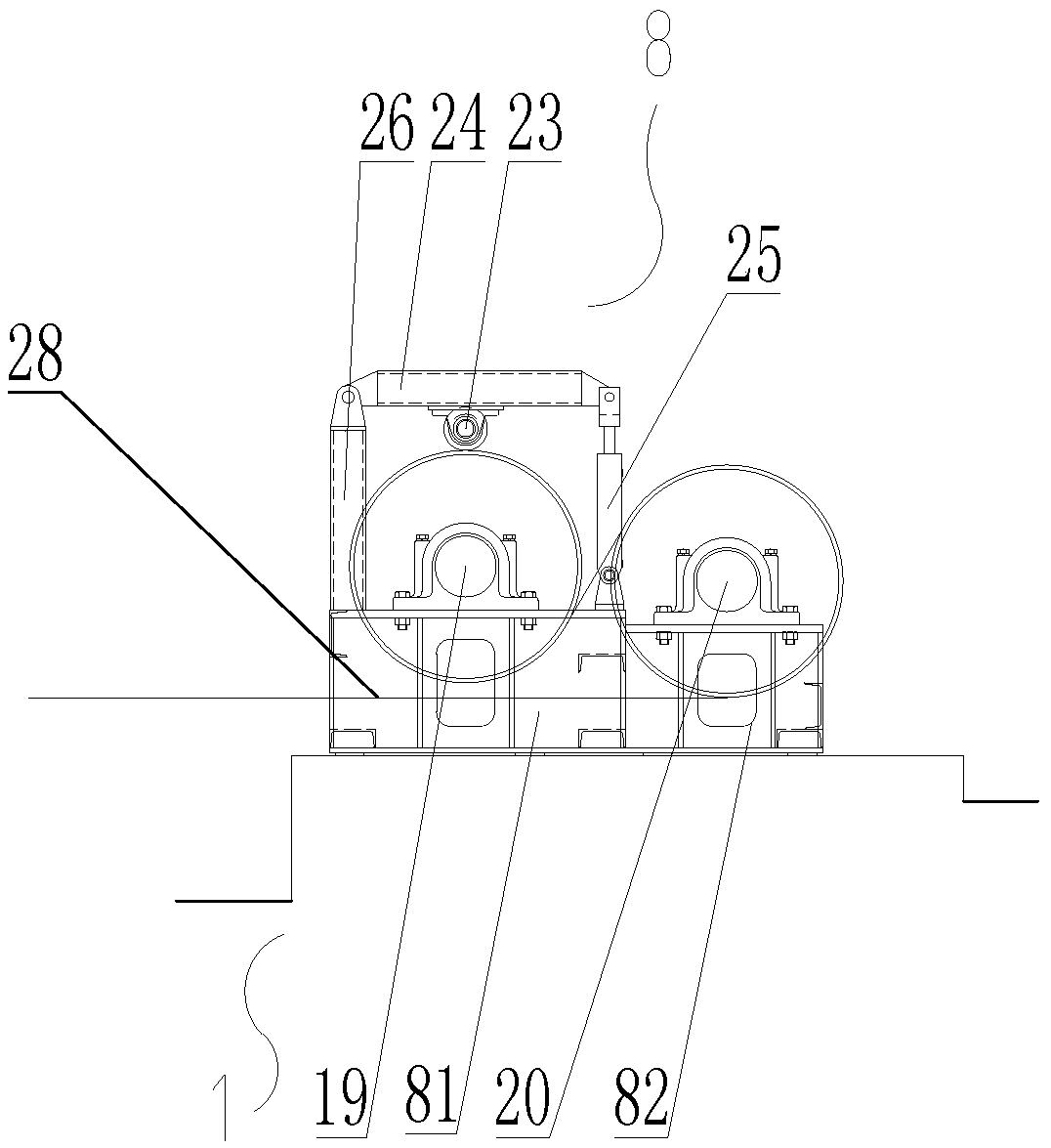

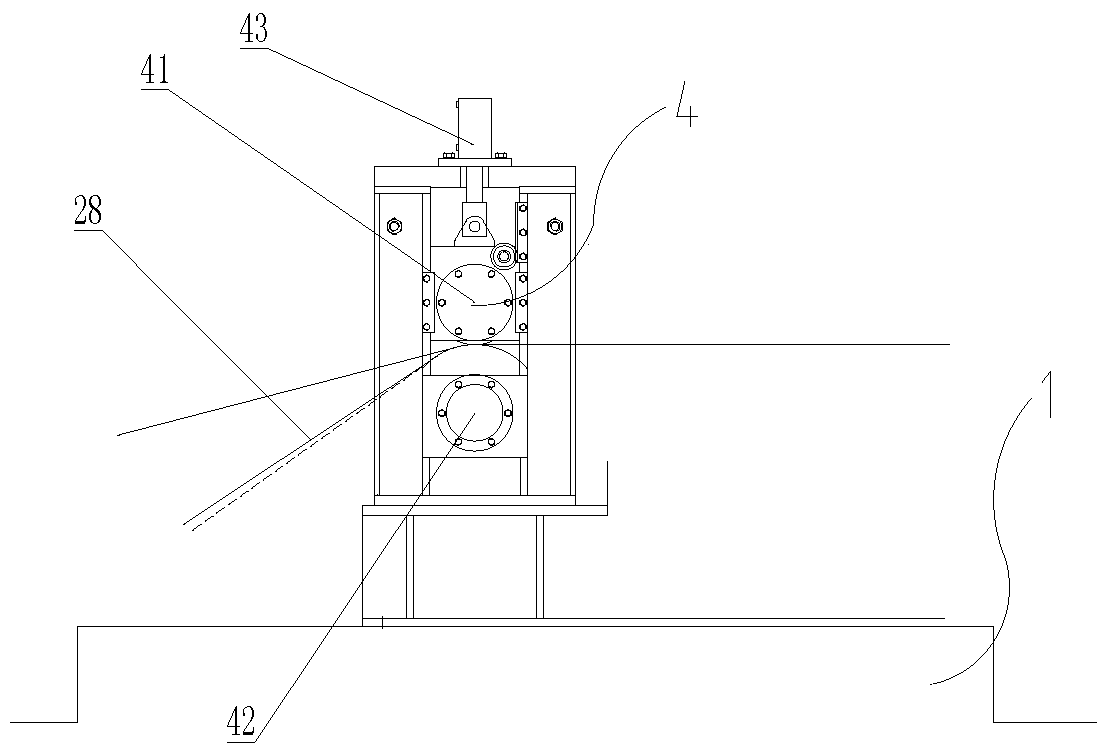

[0016] Such as figure 1 , figure 2 , image 3 As shown, a strip steel tempering machine includes a base 1, and the rolls are installed on the base 1 through a roll support. The rolls include a two-roll tempering machine 2, and one side of the two-roll tempering machine 2 is sequentially provided with a first tension S roller 8, welding machine reserved gap 7, first steering idler roller 6, first hydraulic shear 5, first pinch roller 4, uncoiler 3, and the other side of the two-roller skin passer 2 is sequentially provided with a second The tension S roller 9, the second pinch roller 10, the second hydraulic shear 11, the second diverting roller 12, the winder 13, and the side of the winder 13 and the uncoiler 3 are respectively equipped with a lifting trolley 27; The tempering machine 2 comprises an upper roller 21 and a lower roller 22 arranged symmetrically up and down respectively on the upper base 14 and the lower base 15, and the upper end of the upper roller 21 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com