Needle group structure for embroidery adhesion machine

A technology of patching machines and needle groups, which is applied to the mechanism of embroidery machines, embroidery machines, automatic control embroidery machines, etc., can solve the problems of time-consuming, laborious, limited stability, etc., and achieve fast and convenient positioning, high practicability, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

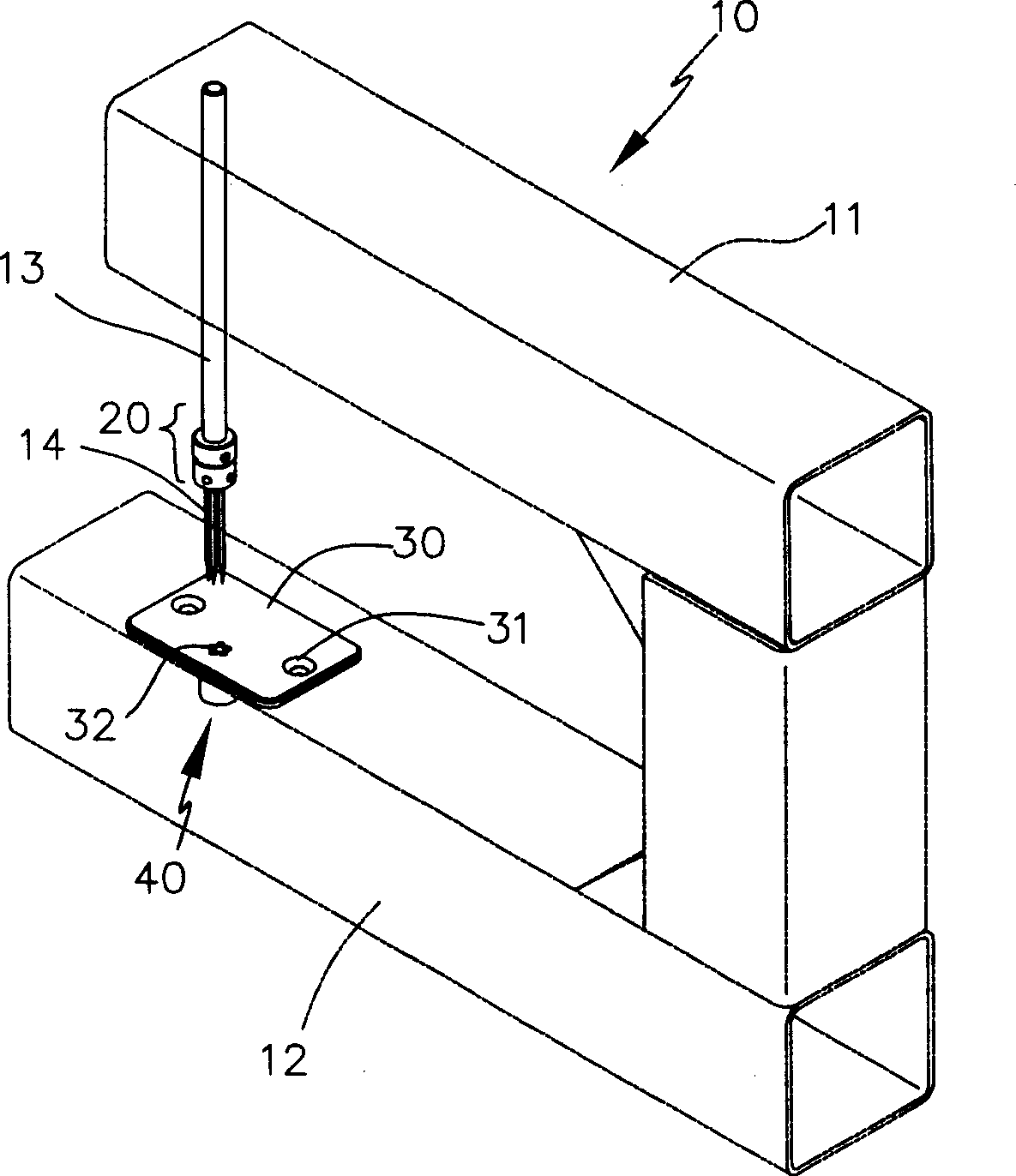

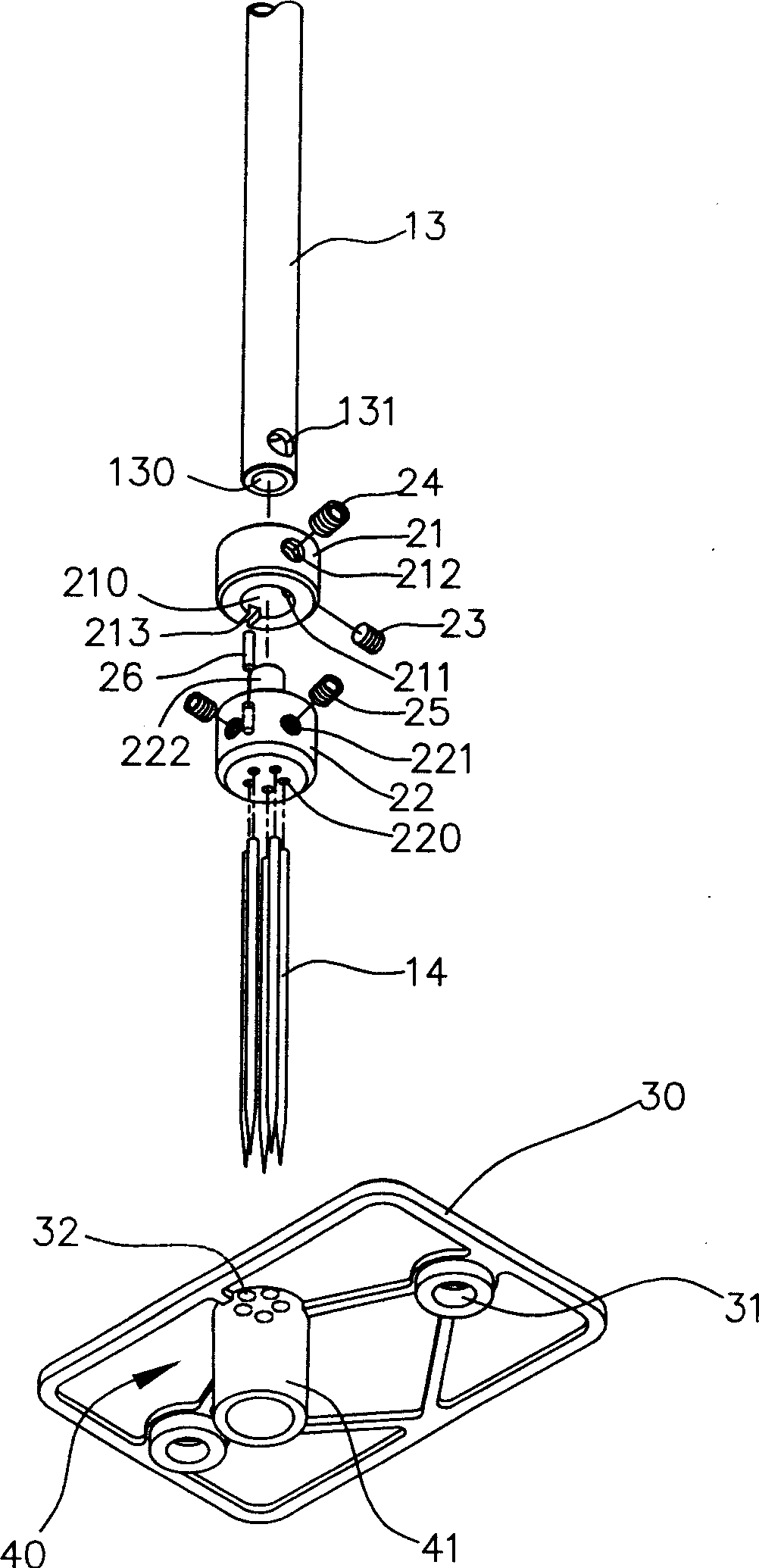

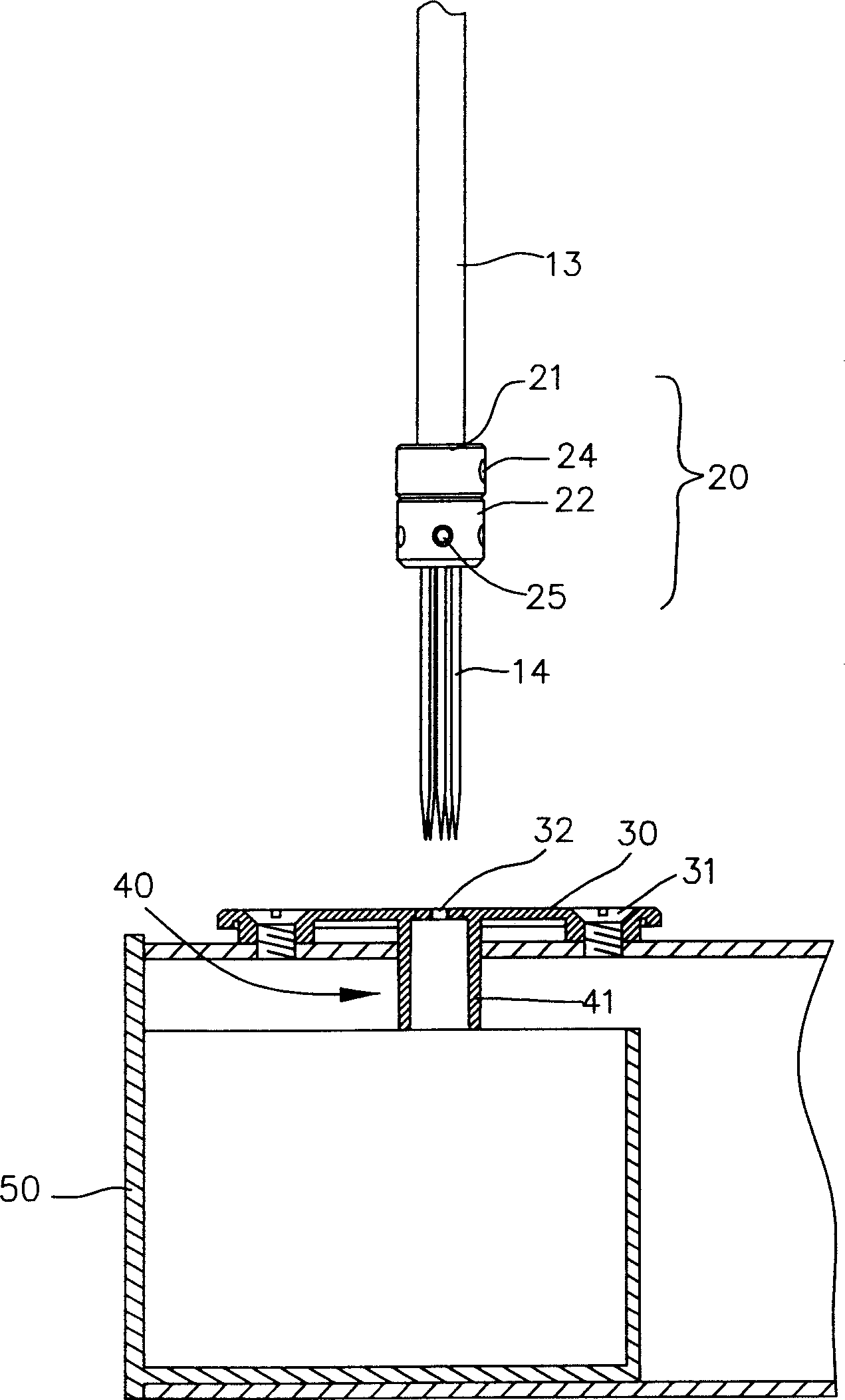

[0039] Example 1, please refer to Figure 1-Figure 3 As shown, the structure of the host machine 10 of the present invention has a cantilever 11, and the bottom of the cantilever 11 is connected with a horizontal machine base 12, and the end of the cantilever 11 drives a needle bar 13 with a driving device, which is the same as a conventional sewing machine It is not the key point of the present invention so it is not intended to go into details here; and the end of its needle bar 13 is provided with an array of needles 14 in addition, and a quick coupling device 20 is provided between its needles 14 and needle bars 13, and the mechanism below the needles 14 A needle plate 30 is provided on the base 12, a shielding device 40 is provided under the needle plate 30, and a crumb receiving body 50 is provided at the port of the machine base 12 to receive the cloth crumbs falling from the needle plate 30; It becomes an automatic embroidery appliqué machine with high security and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com