Die for producing computer display screen base and guide structure thereof

A guide structure and mold technology, applied in the field of molds, can solve problems such as jamming, limited service life and effect of guide posts and guide sleeves, long friction between guide posts and guide sleeves, etc. The effect of reducing the amount of heat generation and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

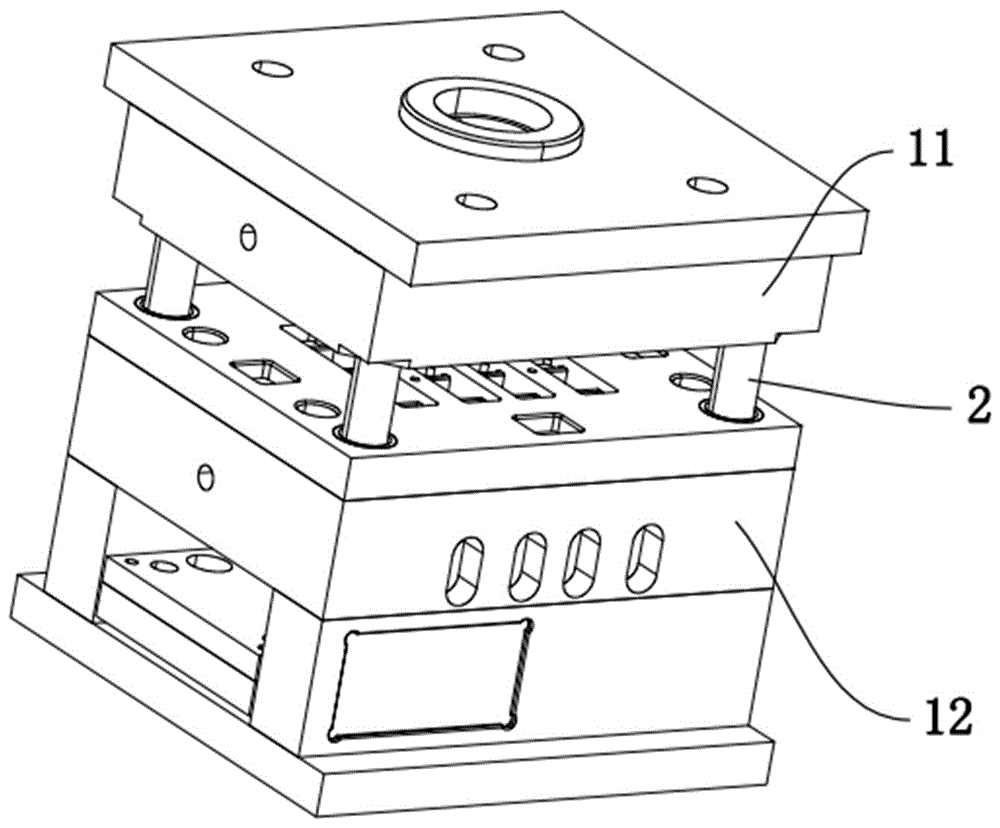

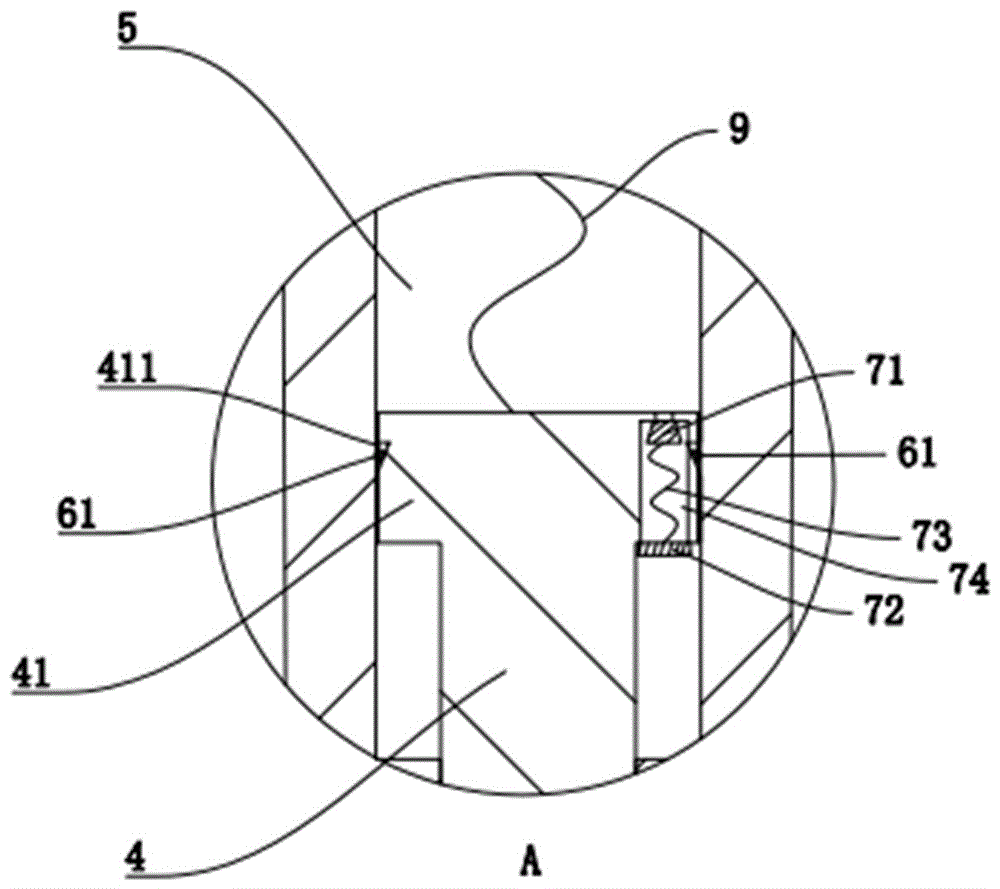

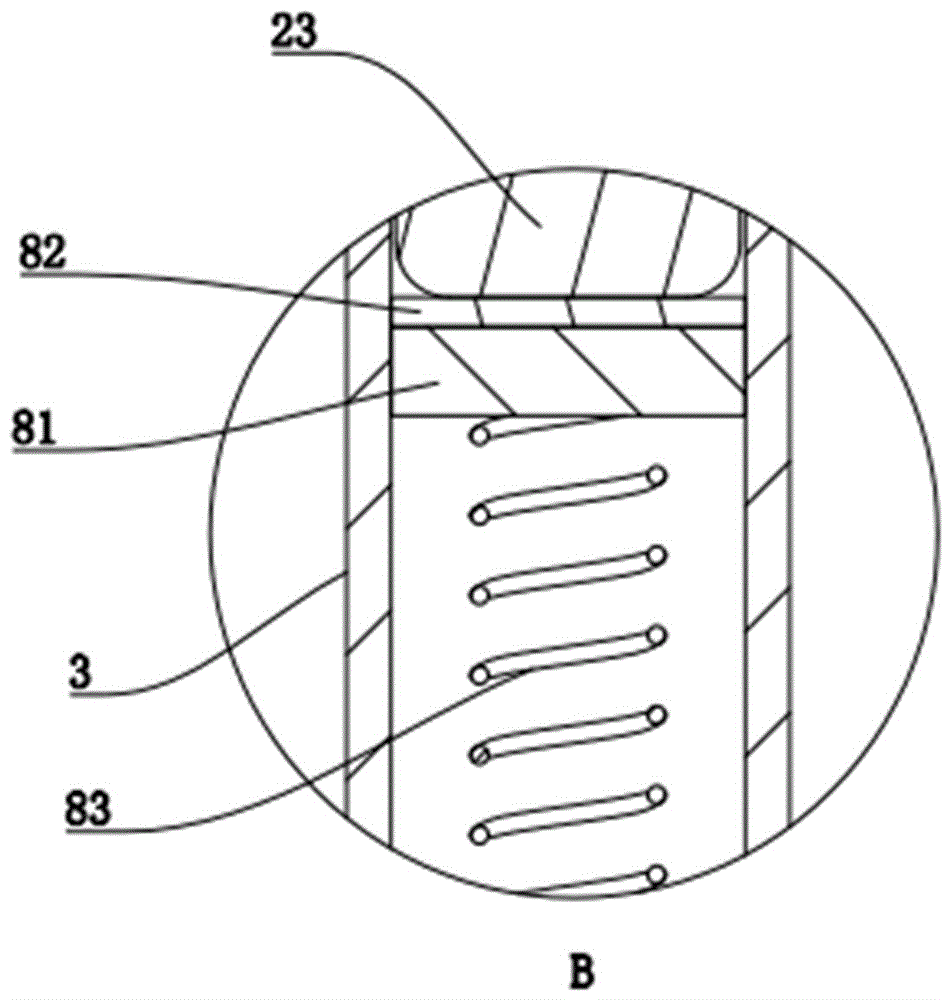

[0037] Embodiment 1, a kind of mold that is used to produce computer display screen base and its guiding structure, refer to the attached figure 1 , is the state diagram of the mold when the mold is opened. At this time, the cooperation between the guide post 2 and the guide sleeve 3 is in the figure 2 status, please refer to the attached image 3 , guide column 2 is divided into fixed column 21 fixed with movable mold 12 here, a second movable column 22 and first movable column 23, between second movable column 22 and fixed column 21, first movable column 23 and The connection between the second movable columns 22 is realized through the interspersed column 4 and the sliding chamber 5 , and the end of the intersecting column 4 is provided with a sliding block 41 which is slidably connected with the sliding chamber 5 .

[0038] A one-way air outlet structure is provided on the sliding block 41, see the attached Figure 4 , including a mouth hole 74 arranged on the sliding b...

Embodiment 2

[0042] Embodiment two, see appendix Figure 6 and 7 The difference from Embodiment 1 lies in the change of the one-way air intake structure. Here, a cone-shaped second sealing ring 62 is set on the side ring wall of the sliding block 41, and the periphery of the second sealing ring 62 is in line with the sliding block. The inner wall of the sliding chamber 5 is in conflict, and the large end opening of the second sealing ring 62 in contact with the inner wall faces the inside of the sliding chamber 5, so that when the sliding block 41 slides to the inside of the sliding chamber 5, the air in the sliding chamber 5 Compressed, the compressed air will reversely act on the second sealing ring 62, forcing the large end opening of the second sealing ring 62 to expand and squeeze the inner wall of the sliding chamber 5 to form an effective seal, and the air will not be able to Discharge from the gap between the sliding block 41 and the sliding chamber 5; when the sliding block 41 sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com