Smart card overturning module

A card and card flipping technology, applied in the field of smart card flipping modules, can solve problems such as inability to use the module, slow speed, and inappropriate flipping, and achieve the effects of improving customer satisfaction, reducing the phenomenon of card flipping, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

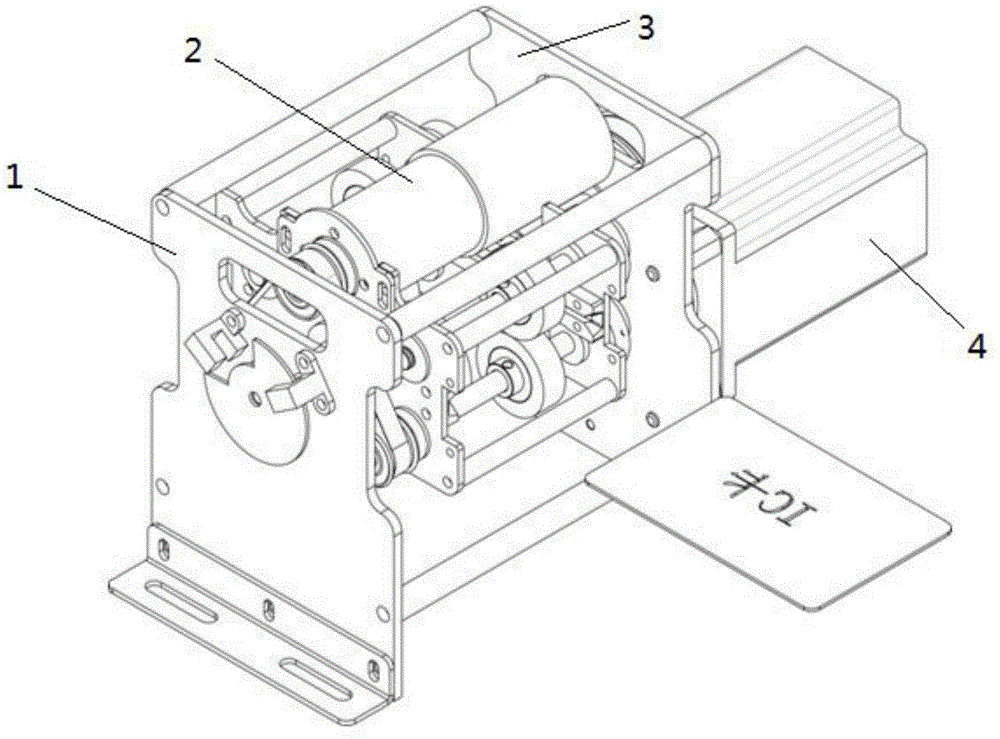

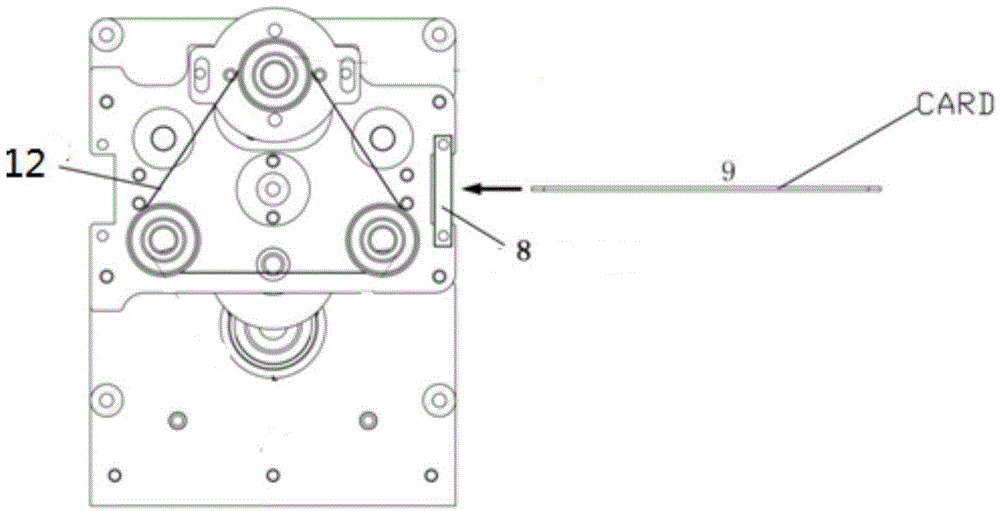

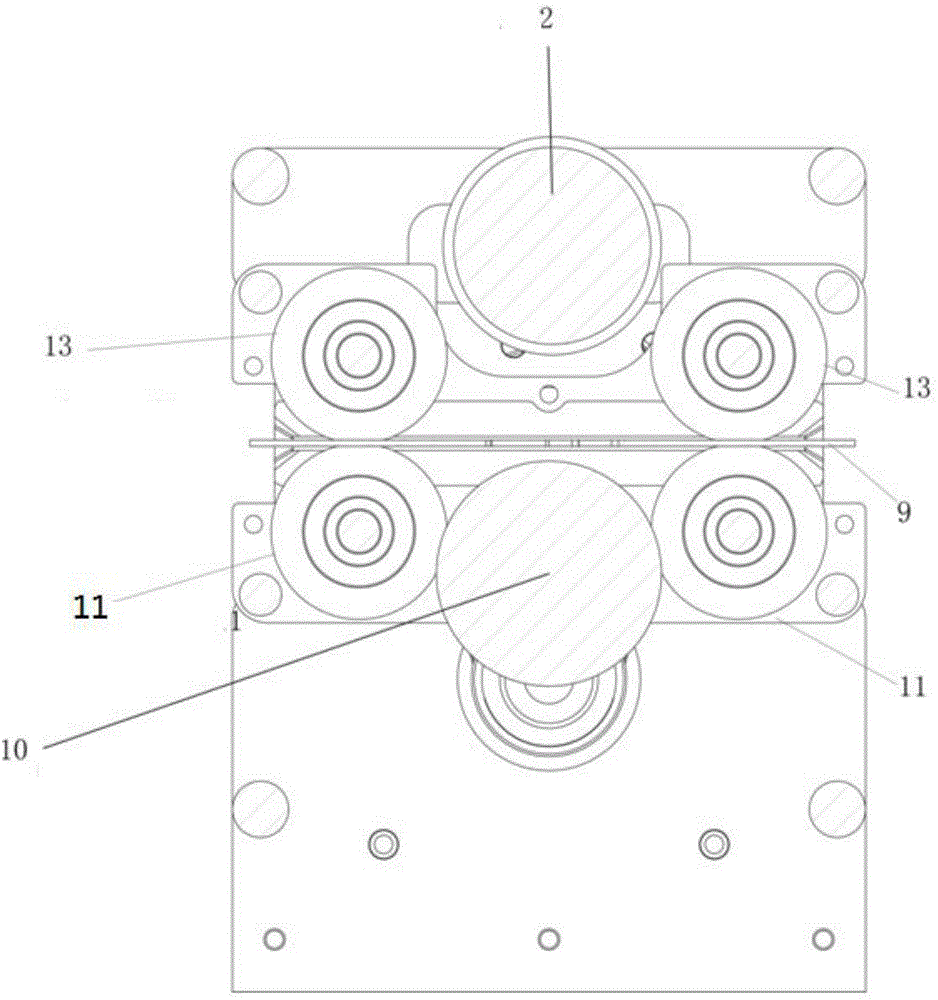

[0021] see Figure 1-6 , a smart card flip module, the smart card flip module is installed on the base of the card printer, the card flip module is generally used in cooperation, and two or more card surface information printing mechanisms are used in conjunction , the first card surface information printing mechanism prints the front information of the card, and after the card is turned 180 degrees by the card turning module, it is sent to the second card surface information printing device to print the reverse side of the card, and the second card surface information is printed After the equipment prints the information on the back of the card, it is sent to the second card turning module, which then turns the card 180 degrees and sends it out from the front. Regarding the increase in the number of card-turning modules, it can be increased accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com