Turntable

A technology of turntable and rotating table, which is applied in the direction of workbench, mechanical energy control, electrical components, etc. It can solve the problems of insufficient bearing capacity, inability to adapt to parts of different sizes, overturning, etc., and achieve enhanced load capacity, simple structure, and improved transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

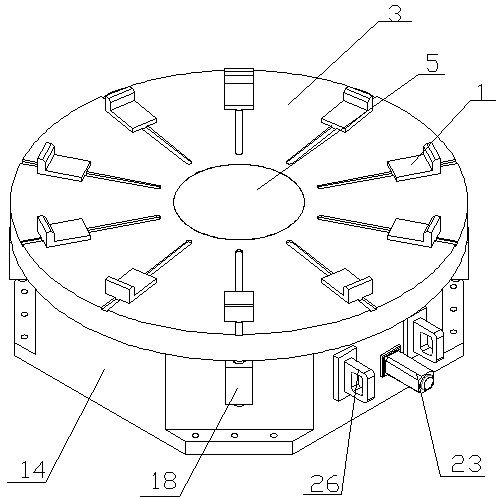

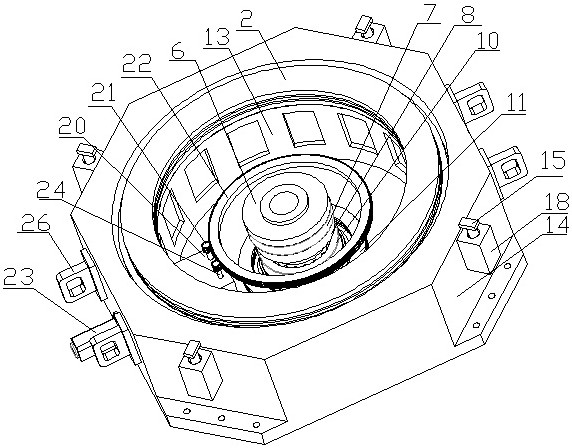

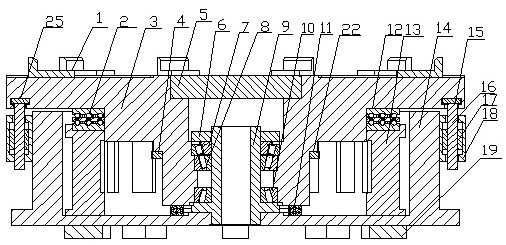

[0022] Such as figure 1 , figure 2 with image 3 As shown, the turntable of the present invention is mainly composed of a rotary support system, a drive system, a leveling system, and a deceleration and locking system. The rotary support system includes a base 14 and a rotating table 3 supported on the base 14. The body of the rotating table 3 is a revolving body, and a through hole is provided in the center as a seat hole. A cover plate 5 is provided on the upper end of the seat hole. 14 is connected with the rotary table 3 through the main shaft 9 and the bearing group arranged in the seat hole. Among the end faces of the ends, the end face of one end is a working plane, the upper surface of the cover plate 5 is flush with the working plane, and more than three trapezoidal grooves are symmetrically arranged in the center of the working plane, and the trapezoidal grooves are opened along the radial direction of the rotary table top 3, Each trapezoidal groove is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com