Multi-liquid transmission rotary device and pipe grabber

A slewing device, multi-fluid circuit technology, applied in the direction of pipe components, pipe laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problem that hydraulic oil pipes cannot achieve dynamic and static state transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

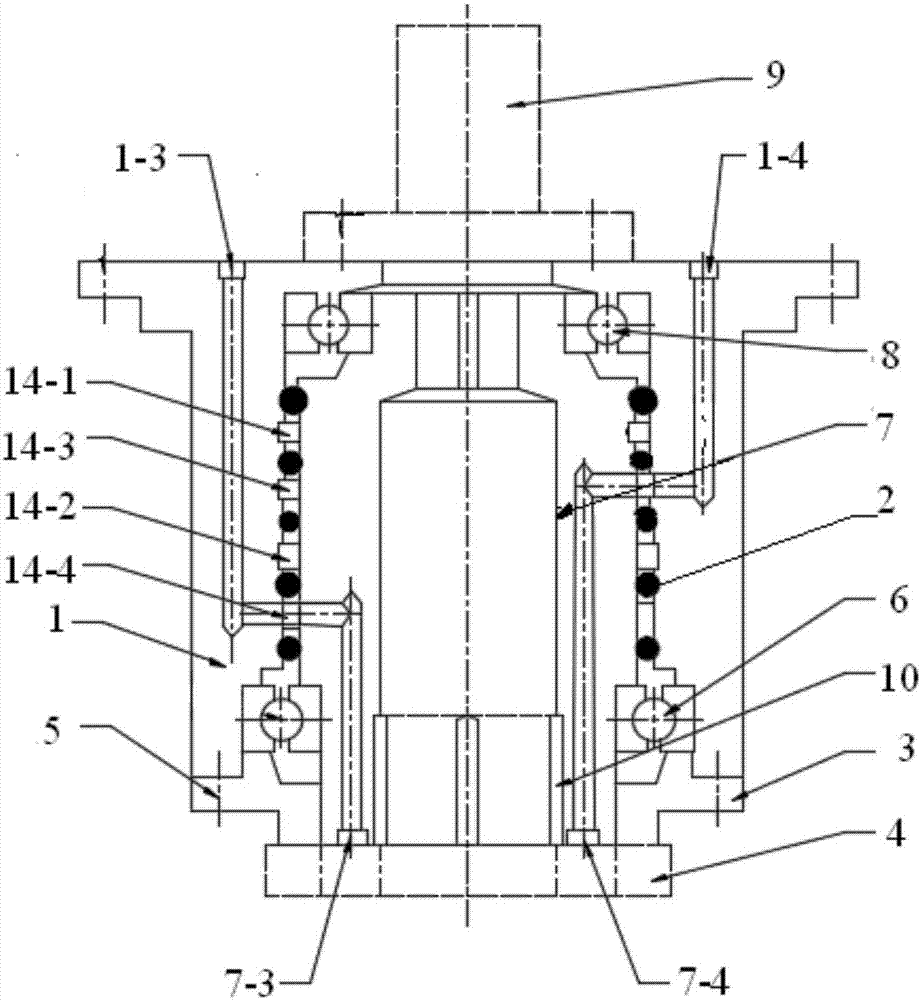

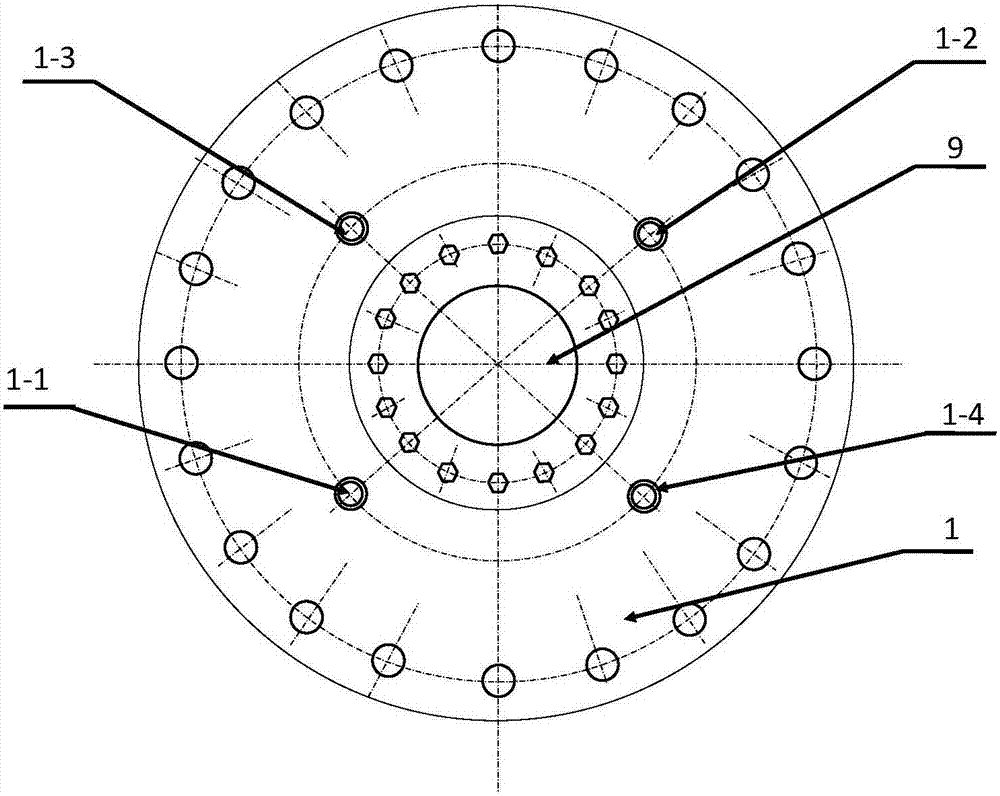

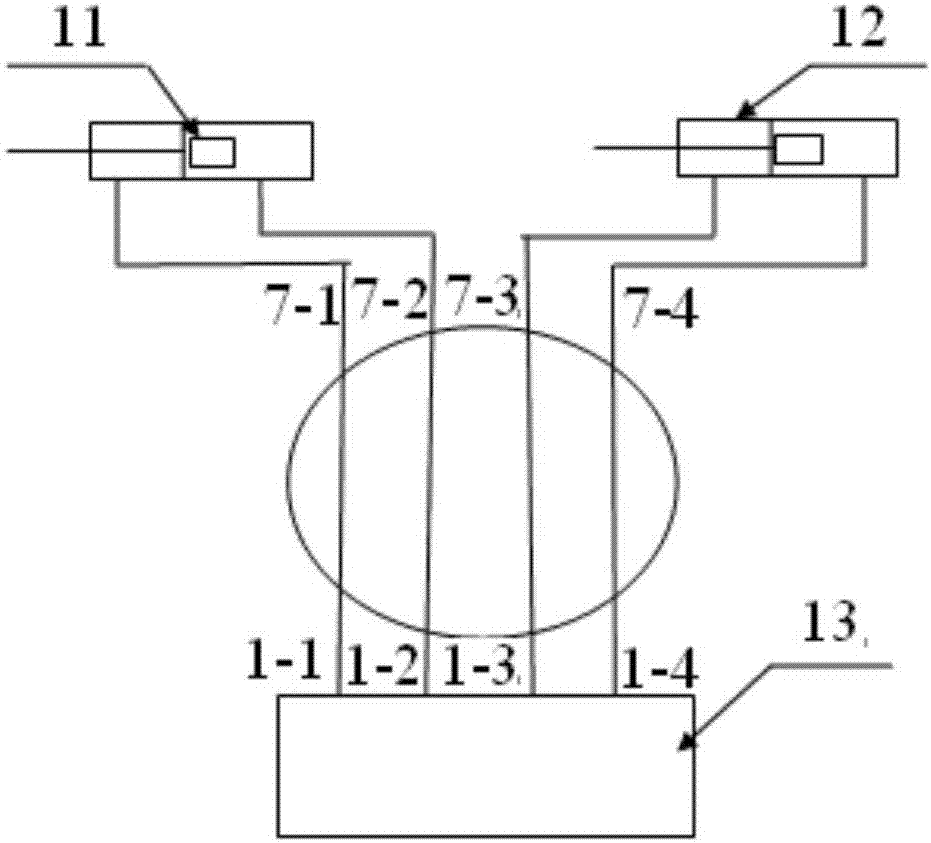

[0038] like figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention provides a multi-fluid transmission rotary device, which is applied to a special pipe grabber, wherein the pipe grabber includes a side thrust hydraulic cylinder group 11, a pipe grab hydraulic cylinder group 12 and a control system valve group 13. The multi-fluid transmission rotary device includes: a fixed sleeve 1, a rotary mechanism and a driving cylinder 9.

[0039] The fixed sleeve 1 is provided with a first oil pipe 1-1, a second oil pipe 1-2, a third oil pipe 1-3 and a fourth oil pipe 1-4, the first oil pipe 1-1, the second oil pipe 1-2, the third oil pipe The oil pipe 1-3 and the fourth oil pipe 1-4 are respectively connected with the valve group 13 of the control system.

[0040] The slewing mechanism is arranged at the center of the fixed sleeve 1, and the slewing mechanism is provided with a fifth oil pipe 7-1, a sixth oil pipe 7-2, a seventh oil pipe 7-3 and an eighth ...

Embodiment 2

[0054] like figure 1 , figure 2 As shown, a multi-fluid transmission rotary device provided in the embodiment of the present application drives the rotary drive cylinder 9 to rotate when performing rotary work, so that the rotary shaft 7 is rotated relative to the fixed sleeve 1 under the action of the driving force of the rotary drive cylinder 9 sports. The first bearing 6 and the second bearing 8 are fixed in the inner circular step of the fixed sleeve 1, and at the same time, the rotating shaft 7 is fixed between the first bearing 6 and the second bearing 8, so that the rotating shaft 7 rotates smoothly and the rotation resistance is small .

[0055] combine image 3 As shown, the multi-fluid transmission rotary device provided by the embodiment of the present application is between the fixed sleeve 1 and the rotating shaft 7, providing a 2-in-2 hydraulic cylinder group 11 and a pipe-grabbing hydraulic cylinder group 12 in the outer rotary structure. Out of the hydraul...

Embodiment 3

[0057] The embodiment of the present application also provides a pipe grabber, the pipe grabber includes the above-mentioned multi-liquid path transmission rotary device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com